Description

Product Overview

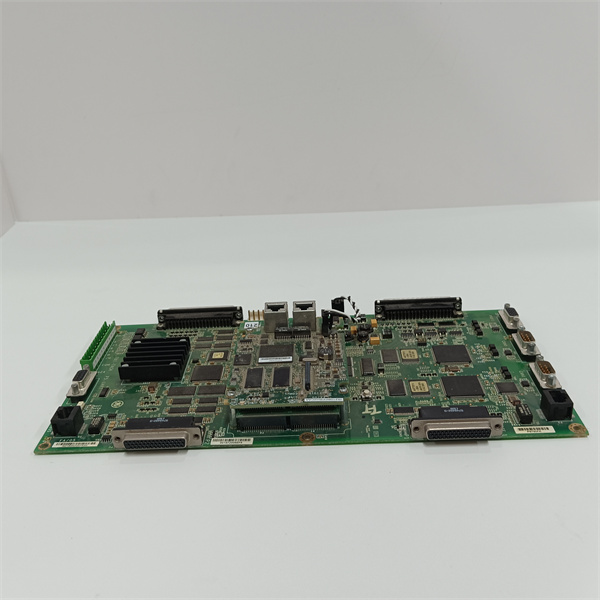

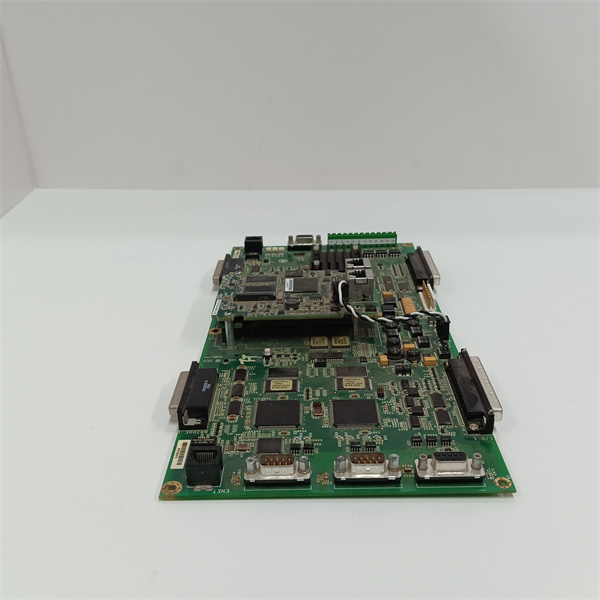

The GE IS210MACCH1AGG is a high – performance processor card that forms an integral part of the GE Mark VIe control system. Engineered by General Electric, a global leader in industrial technology, this card is designed to meet the exacting demands of real – time control and data processing in a wide range of industrial applications.

At its core, the GE IS210MACCH1AGG features a high – speed embedded processor. This powerful computational engine enables the card to execute complex control algorithms with precision and efficiency. Whether it’s managing the intricate operations of a gas turbine or ensuring seamless coordination in an industrial automation setup, the IS210MACCH1AGG can handle the load. It supports multi – tasking capabilities, allowing it to simultaneously manage multiple control functions and data streams. This is crucial in large – scale industrial systems where numerous processes need to be monitored and controlled in real – time. By integrating the GE IS210MACCH1AGG into an industrial control infrastructure, users can expect enhanced system performance, improved reliability, and optimized operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210MACCH1AGG |

| Manufacturer | GE |

| Product Type | Processor Card |

| Compatible System | GE Mark VIe control system |

| Processor Type | High – performance embedded processor |

| Communication Interfaces | Ethernet, RS – 232, RS – 485 |

| Power Requirements | Industrial standard input voltage |

| Operating Temperature Range | – 30°C to 70°C |

| Storage Temperature Range | – 40°C to 85°C |

| Humidity Range | 5% – 95% non – condensing |

| Dimensions | [Specify if available] |

| Weight | [Specify if available] |

| Data Processing Speed | High – speed for real – time applications |

IS210MACCH1AGG

Main Features and Advantages

High – Performance Processing

The GE IS210MACCH1AGG is equipped with a high – speed embedded processor. This allows it to execute complex control algorithms rapidly, making it suitable for applications where split – second decisions are crucial. For example, in a gas turbine control system, the card can quickly process data from various sensors and adjust the turbine’s operation parameters to maintain optimal performance.

Multi – Tasking Capability

With its ability to support multi – tasking, the card can manage multiple control functions simultaneously. In an industrial automation plant, it can oversee the operation of conveyors, robotic arms, and other equipment at the same time, ensuring smooth coordination and efficient production. This multi – tasking feature enhances the overall productivity of the system.

Robust Connectivity

Featuring a variety of communication interfaces such as Ethernet, RS – 232, and RS – 485, the IS210MACCH1AGG offers seamless connectivity. It can easily communicate with other devices within the industrial network, including sensors, actuators, and other control units. This enables data sharing and system integration, allowing for a more comprehensive and unified control environment.

Wide Operating Range

Designed to operate in harsh industrial environments, the card has a wide operating temperature range from – 30°C to 70°C and can withstand humidity levels of 5% – 95% non – condensing. This makes it suitable for use in factories, power plants, and other industrial settings where environmental conditions can vary significantly.

Application Field

Power Generation

In power generation facilities, the GE IS210MACCH1AGG is extensively used in gas and steam turbine control systems. It processes data from sensors monitoring parameters like temperature, pressure, and speed. Based on this data, it adjusts the turbine’s operation to ensure efficient power generation. For example, in a natural gas – fired power plant, the card helps in optimizing the combustion process of the gas turbine, leading to increased energy output and reduced fuel consumption.

Industrial Automation

In industrial automation plants, this processor card plays a vital role. It controls and coordinates the operation of various components such as programmable logic controllers (PLCs), robotic arms, and conveyor belts. In an automotive manufacturing plant, the IS210MACCH1AGG can manage the movement of robotic arms during the car assembly process, ensuring precise and timely operations. It also enables real – time monitoring and control, allowing for quick response to any production issues.

Energy Management

For energy management systems, the GE IS210MACCH1AGG is used to monitor and control energy – consuming devices. In a large commercial building, it can manage the operation of HVAC systems, lighting, and other electrical equipment. By analyzing energy usage data, it can implement energy – saving strategies, such as adjusting the temperature setpoints of air – conditioning units during off – peak hours, thereby reducing overall energy consumption.

IS210MACCH1AGG

Related Products

- GE IS210MACCH1AFG: A related processor card in the same product line. It may have similar basic functions to the IS210MACCH1AGG but could differ in terms of specific performance characteristics or interface options, catering to different subsets of industrial applications.

- GE IS210MACCH2AGG: This is another model within the series. It might offer enhanced features, such as higher processing power or additional communication capabilities, making it suitable for more complex industrial control setups compared to the IS210MACCH1AGG.

- GE IS210AEACH1A: A master input/output board. It can work in tandem with the GE IS210MACCH1AGG in an industrial control system. The IS210MACCH1AGG can process data, and the IS210AEACH1A can handle the input and output of signals to and from external devices.

- GE IS420UCECH1B: A Mark VIe controller. It can be integrated with the IS210MACCH1AGG to provide a more comprehensive control solution. The IS210MACCH1AGG focuses on data processing, while the IS420UCECH1B can manage overall control functions in the system.

- GE IS220PAOCH1A: An analog output module. It can be used in conjunction with the GE IS210MACCH1AGG to output analog signals based on the processed data from the processor card. This is useful in applications where analog – controlled devices need to be regulated.

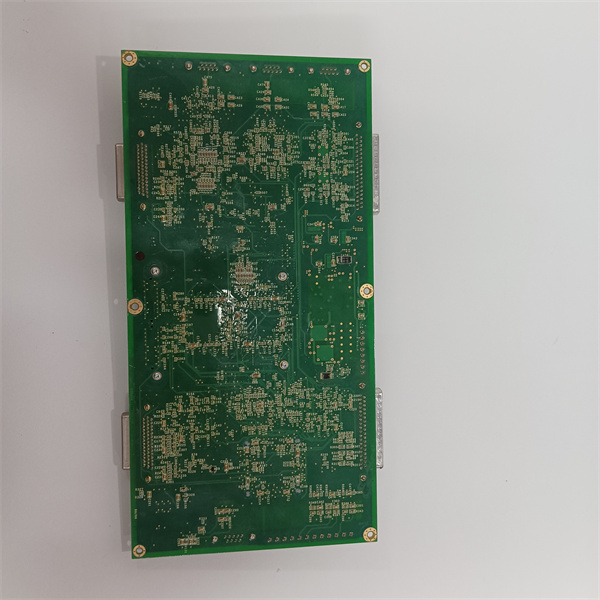

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210MACCH1AGG, carefully review the installation manual provided by GE. Ensure that the Mark VIe control system where it will be installed is powered off and properly grounded. Check the physical condition of the card for any signs of damage during transit. Verify that the communication interfaces and power requirements of the card match the existing system infrastructure. Make sure to handle the card with anti – static precautions to avoid electrostatic discharge that could damage the sensitive components.

Maintenance recommendations: Regularly monitor the GE IS210MACCH1AGG for any signs of overheating. Check the communication interfaces for any loose connections or signal irregularities. Periodically update the card’s firmware as recommended by GE to benefit from the latest features and security enhancements. Clean the card gently to remove dust and debris, as these can accumulate and affect the performance. If any issues arise, such as processing errors or communication failures, refer to the troubleshooting guide in the product manual. Consider scheduling preventive maintenance checks at regular intervals to ensure long – term reliable operation.

Maintenance recommendations: Regularly monitor the GE IS210MACCH1AGG for any signs of overheating. Check the communication interfaces for any loose connections or signal irregularities. Periodically update the card’s firmware as recommended by GE to benefit from the latest features and security enhancements. Clean the card gently to remove dust and debris, as these can accumulate and affect the performance. If any issues arise, such as processing errors or communication failures, refer to the troubleshooting guide in the product manual. Consider scheduling preventive maintenance checks at regular intervals to ensure long – term reliable operation.

Product Guarantee

GE stands firmly behind the quality of the GE IS210MACCH1AGG processor card. The product undergoes rigorous quality control procedures during manufacturing to meet high – industry standards. GE offers a comprehensive warranty for the IS210MACCH1AGG, covering any defects in materials and workmanship. Their global network of technical support teams is available to assist customers. Whether it’s answering installation – related questions, helping with complex troubleshooting, or providing advice on maintenance, GE’s experts are dedicated to ensuring the long – term reliable operation of the processor card. This reflects GE’s confidence in the product and its commitment to customer satisfaction.