Description

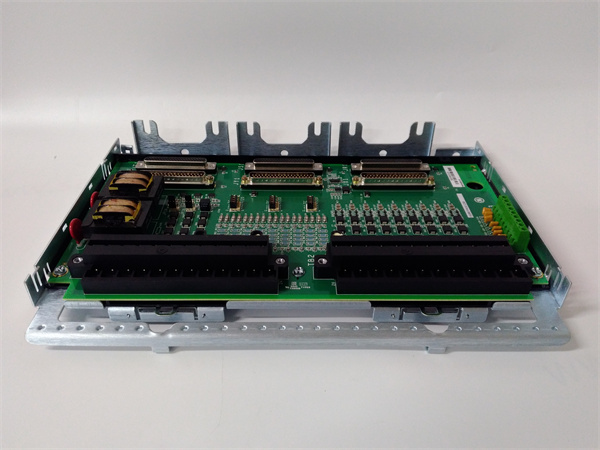

Product Overview

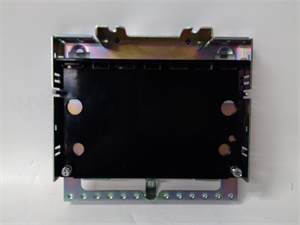

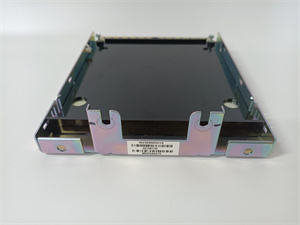

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230STAOH2A |

| Manufacturer | GE |

| Product Type | Analog Output Module |

| Output Channels | 8 |

| Output Voltage Range | ± 10 V |

| Resolution | 16 – bit |

| Sampling Rate | 100 kHz |

| Operating Voltage | 24 V DC |

| Environmental Rating | IP20 |

| Weight | 1.5 kg |

| Dimensions | 160 x 100 x 70 mm |

| Isolation Voltage | 500 Vrms |

| Communication Interface | Compatible with Mark VI system protocols |

IS200TTURH1CFD

Main Features and Advantages

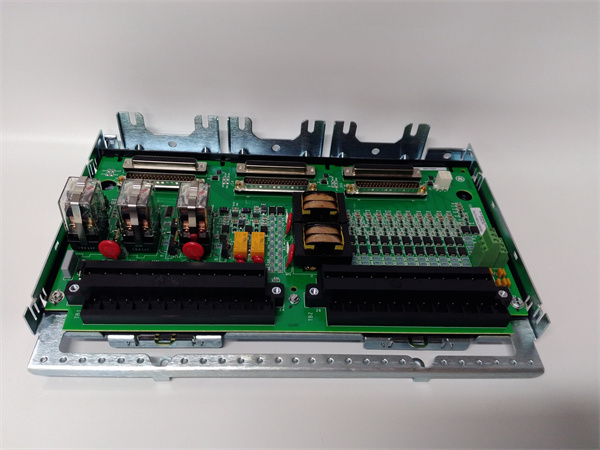

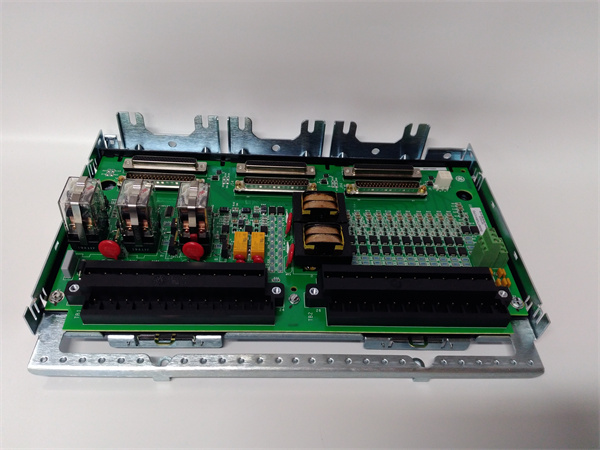

High – Precision Output: The GE IS230STAOH2A offers 16 – bit resolution, ensuring highly accurate analog signal output. This precision is crucial for applications where even the slightest deviation in control signals can lead to significant process inefficiencies. It allows for the fine – tuning of equipment operation, resulting in more consistent and reliable industrial processes.

Multiple Output Channels: Equipped with 8 output channels, the module provides a high – density solution. This enables it to control multiple field devices simultaneously, reducing the need for additional modules and simplifying the overall system architecture. It is particularly beneficial for complex industrial setups with numerous control points.

Fast Sampling Rate: With a sampling rate of 100 kHz, the module can quickly respond to changes in control commands. This rapid response time ensures that the control system can adapt to dynamic industrial processes in a timely manner, enhancing the overall system’s ability to handle real – time control requirements.

Reliable in Harsh Environments: Designed with an IP20 environmental rating, the IS230STAOH2A can withstand common industrial environmental conditions, such as dust and limited exposure to moisture. Its robust construction and reliable performance make it suitable for continuous operation in demanding industrial settings, minimizing the risk of system failures due to environmental factors.

Easy Integration: As part of the Mark VI series, the module is seamlessly compatible with other components in the Mark VI system. This compatibility simplifies the integration process, allowing for quick and hassle – free deployment in existing or new industrial automation projects. It reduces the complexity of system configuration and maintenance, saving both time and resources.

IS200TPROS1CBB

Application Field

Industrial Manufacturing: In manufacturing facilities, this module is employed to control various types of machinery. For example, it can precisely control the speed of motors in conveyor systems, adjust the position of robotic arms, or regulate the flow of materials in production lines. Its high – precision analog output capabilities enable manufacturers to achieve consistent product quality and efficient production processes.

Process Control in Chemical and Petrochemical Industries: In chemical and petrochemical plants, the IS230STAOH2A is crucial for controlling chemical reactions, fluid flow, and temperature. It can control the opening and closing of valves to regulate the flow of chemicals, adjust the speed of pumps, and manage the operation of heaters and coolers. This precise control is essential for ensuring the safety and efficiency of chemical processes and for producing high – quality chemical products.

Water and Wastewater Treatment: In water treatment plants, the module is used to control the operation of pumps, valves, and other equipment involved in the water treatment process. It can adjust the dosage of chemicals for water purification, control the flow rate of water through treatment tanks, and manage the operation of filtration systems. In wastewater treatment, it helps in the proper treatment and disposal of sewage by controlling the relevant equipment, ensuring compliance with environmental regulations.

Related Products

GE IS230SNRLH2A: This could be another module in the same product family, perhaps with different functionality such as signal conditioning or communication – related tasks. It may work in tandem with the IS230STAOH2A to enhance the overall performance and capabilities of the industrial automation system.

GE Mark VI System Controllers: These are the central control units of the Mark VI system. The IS230STAOH2A is designed to interface with these controllers, receiving control commands from them and outputting analog signals based on those commands to control field devices.

GE Power Supply Modules for Mark VI Series: To ensure the proper operation of the IS230STAOH2A, reliable power supply modules are required. These power supply modules are specifically designed for the Mark VI series and provide the stable 24 V DC power that the IS230STAOH2A needs to function effectively.

GE Communication Modules for Mark VI: These modules facilitate communication between the IS230STAOH2A and other components in the industrial network. They can support various communication protocols, enabling the module to transmit and receive data, status information, and control commands, thus integrating the module into a larger, interconnected industrial automation system.

Installation and Maintenance

Maintenance recommendations: Regularly monitor the GE IS230STAOH2A for any signs of abnormal operation. Check the output signals using appropriate testing equipment to ensure they are within the expected range. Clean the module periodically to remove dust and debris that could potentially affect its performance, especially in dusty industrial environments. If any error indicators on the module are activated, refer to the troubleshooting section of the product manual. In case of component failure, replace the faulty parts with genuine GE – approved components. Additionally, periodically review and update the module’s configuration settings to adapt to any changes in the industrial process or control system requirements.