Description

Product Overview

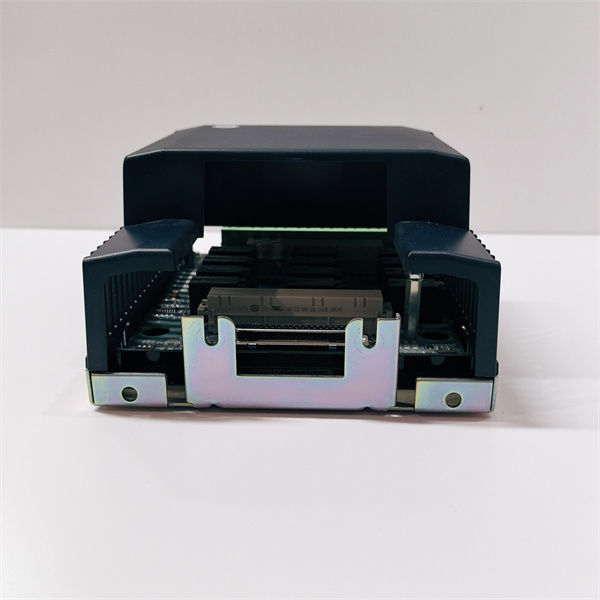

The GE IS410SRLYS2A is a pivotal single – simplex relay output terminal board within the GE Mark VIe series. It is designed to play a crucial role in industrial control systems, providing reliable relay – based output for various applications. With its 7 – inch DIN rail S – type card design, it offers compatibility with other S – type terminal boards, making system integration a seamless process. This module can accept YD OA I/O components and features 48 client terminals, which are used to supply 12 form C relay output circuits. Each relay has isolated contact pairs for position feedback to the I/O component, enhancing the accuracy and reliability of the control system. The GE IS410SRLYS2A is engineered to meet the high – demand requirements of industrial automation, ensuring stable and efficient operation in complex industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS410SRLYS2A |

| Manufacturer | General Electric |

| Product Type | Relay Output Terminal Board |

| Relay Configuration | 12 form C relays |

| Relay Contact Ratings | Multiple ratings available to suit different loads |

| Terminal Count | 48 client terminals |

| Mounting Type | 7 – inch DIN rail S – type card |

| Input Voltage Range | Compatible with specific voltage levels in industrial settings |

| Output Current Capacity | Adequate for driving common industrial loads |

| Operating Temperature | – 10 °C to 55 °C |

| Relative Humidity | 5% – 95% non – condensing |

| Dimensions | Specific dimensions suitable for standard industrial enclosures |

| Weight | Appropriate for easy installation and handling |

IS410SRLYS2A IS400SRLYS2ABB

Main Features and Advantages

Reliable Relay Performance: The 12 form C relays in the GE IS410SRLYS2A are built to endure the rigors of industrial use. They can handle a wide range of load types, from small – signal devices to larger industrial actuators. The isolated contact pairs for position feedback ensure that the control system always has accurate information about the relay’s state, minimizing the risk of misoperation.

Flexible Power Options: When paired with certain sub – boards, the IS410SRLYS2A can offer diverse power distribution methods. For example, with the IS400WROBH1A sub – board, it can provide fused and inductive power distribution for the first six relays and a dedicated power supply for the last one. This flexibility allows for customized power solutions based on the specific needs of the connected equipment.

Enhanced Protection: Some sub – boards, like the IS400WROFH1A, add an extra layer of protection. They have a single fuse in series with each relay common connection and provide fuse voltage feedback. This protects the relays and downstream equipment from over – current situations, increasing the overall reliability of the system.

Flexible Power Options: When paired with certain sub – boards, the IS410SRLYS2A can offer diverse power distribution methods. For example, with the IS400WROBH1A sub – board, it can provide fused and inductive power distribution for the first six relays and a dedicated power supply for the last one. This flexibility allows for customized power solutions based on the specific needs of the connected equipment.

Enhanced Protection: Some sub – boards, like the IS400WROFH1A, add an extra layer of protection. They have a single fuse in series with each relay common connection and provide fuse voltage feedback. This protects the relays and downstream equipment from over – current situations, increasing the overall reliability of the system.

Application Field

Power Generation: In power plants, the GE IS410SRLYS2A is used to control critical components in gas and steam turbines. It can precisely operate valves that regulate the flow of fuel or steam, ensuring optimal turbine performance. For instance, it controls the fuel – injection solenoids in gas turbines, adjusting the fuel supply according to the load requirements.

Industrial Automation: In manufacturing plants, this module is employed to control automated machinery. It can drive pneumatic and hydraulic cylinders, which are essential for tasks such as material handling, assembly, and packaging. For example, in an automotive assembly line, it can control the movement of robotic arms that pick and place car parts with high precision.

Oil and Gas: In the oil and gas industry, the IS410SRLYS2A is utilized in various processes. It can control pumps and compressors in pipelines, ensuring the smooth transportation of oil and gas. Additionally, it can be used to operate valves in refineries, regulating the flow of fluids during the refining process.

Industrial Automation: In manufacturing plants, this module is employed to control automated machinery. It can drive pneumatic and hydraulic cylinders, which are essential for tasks such as material handling, assembly, and packaging. For example, in an automotive assembly line, it can control the movement of robotic arms that pick and place car parts with high precision.

Oil and Gas: In the oil and gas industry, the IS410SRLYS2A is utilized in various processes. It can control pumps and compressors in pipelines, ensuring the smooth transportation of oil and gas. Additionally, it can be used to operate valves in refineries, regulating the flow of fluids during the refining process.

Related Products

IS400SRLYS2ABB: Likely related to the IS410SRLYS2A, it may be a complementary or alternative product. It could have different features or be optimized for specific applications within the same industrial control context.

IS400WROBH1A: This sub – board can be used with the IS410SRLYS2A to change its power distribution capabilities, providing more flexibility in powering the relays.

IS400WROFH1A: Adds enhanced protection features to the IS410SRLYS2A by incorporating fuses and fuse voltage feedback in the relay circuits.

GE Mark VIe Series Control Processors: These processors work in tandem with the IS410SRLYS2A, sending control signals to the relay board based on the overall system requirements.

YD OA I/O Components: The IS410SRLYS2A is designed to accept these components, and they work together to expand the input and output capabilities of the industrial control system.

IS400WROBH1A: This sub – board can be used with the IS410SRLYS2A to change its power distribution capabilities, providing more flexibility in powering the relays.

IS400WROFH1A: Adds enhanced protection features to the IS410SRLYS2A by incorporating fuses and fuse voltage feedback in the relay circuits.

GE Mark VIe Series Control Processors: These processors work in tandem with the IS410SRLYS2A, sending control signals to the relay board based on the overall system requirements.

YD OA I/O Components: The IS410SRLYS2A is designed to accept these components, and they work together to expand the input and output capabilities of the industrial control system.

IS410SRLYS2A IS400SRLYS2ABB

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS410SRLYS2A, ensure that the installation area is clean, free of dust, and within the specified temperature and humidity range. Verify the compatibility of the module with the existing control system components, including power supply voltages and communication protocols. Mount the 7 – inch DIN rail securely and then carefully install the IS410SRLYS2A on it. Connect the wiring according to the provided wiring diagrams, making sure all connections are tight to prevent loose contacts.

Maintenance recommendations: Regularly inspect the GE IS410SRLYS2A for any signs of physical damage, such as cracks on the circuit board or loose components. Check the relay contacts for wear and tear, as excessive wear can affect their performance. Monitor the operating temperature of the module, as overheating can lead to failures. If possible, use diagnostic tools to check the functionality of the relays and the position feedback system. Replace any faulty relays or sub – boards promptly to maintain the integrity of the control system.

Product Guarantee

General Electric stands firmly behind the quality of the GE IS410SRLYS2A. The product undergoes stringent quality control procedures during manufacturing to ensure it meets the highest industry standards. GE offers a comprehensive warranty that covers manufacturing defects for a specified period. In case of any such defects, they will provide prompt repair or replacement services. Their team of highly skilled technical experts is always available to offer technical support for installation, operation, and troubleshooting. This commitment not only reflects GE’s confidence in the product but also provides customers with peace of mind, knowing that their industrial control systems are backed by a reliable and reputable company.