Description

Product Overview

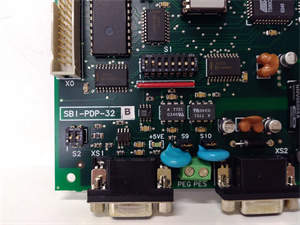

The GE SBI – PDP – 32 is an advanced industrial module crafted by General Electric, renowned for its high – performance capabilities in industrial automation systems. This module is designed to offer reliable data processing and seamless communication, making it a vital component in a wide range of industrial applications.

As a programmable logic relay (PLC) interface card module, the GE SBI – PDP – 32 stands out for integrating logic functions into a compact unit. It can be directly inserted into a module consisting of eight PLC relays, significantly simplifying the system architecture. This integration not only reduces the number of components but also enhances the overall reliability of the system. It is an ideal solution for applications where space is at a premium, yet high – level control and functionality are required. In the realm of industrial automation, the GE SBI – PDP – 32 plays a crucial role in enabling efficient control and monitoring, thereby optimizing production processes and reducing operational costs.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SBI – PDP – 32 |

| Manufacturer | General Electric |

| Product Type | PLC Interface Card Module |

| Input Voltage Range | 9 – 30 VDC |

| Output Voltage Range | 12 – 24 VDC |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Humidity Range | 5% – 95% non – condensing |

| Communication Protocols | Modbus, Profibus, Ethernet/IP |

| Input Channels | 32 |

| Data Processing Rate | Up to 100 MHz |

| Memory Capacity | 1 GB |

| Protection Rating | IP67 |

| Dimensions | 15 x 10 x 5 cm |

| Weight | 0.5 kg |

SBI-PDP-32

Main Features and Advantages

Compact and Integrated Design

The GE SBI – PDP – 32 features an integrated design where logic functions are packed into a small module. This allows for direct insertion into an eight – relay PLC module, simplifying the system structure. The entire PLC logic system, when connected to a group of eight relays, is only 50 millimeters wide, demonstrating its space – saving nature. This compact design is highly beneficial in industrial settings where space is often limited.

Compatibility and Configuration Flexibility

It is compatible with a wide range of Phoenix Contact’s electromechanical and solid – state relays, and can operate across various voltage ranges. Using the Logic + programming software, users can easily configure the system through simple drag – and – drop operations. The software offers commands for setting up timers, counters, thresholds, and more, all of which can be downloaded for free. This flexibility in configuration allows for customization according to specific industrial requirements.

Hot – Swappable Relays

Equipped with hot – swappable relay functionality, individual relays can be replaced without shutting down the entire system. This feature is a game – changer in terms of maintenance, as it significantly reduces maintenance time and costs. In industrial operations where downtime can be costly, the GE SBI – PDP – 32‘s hot – swappable relays ensure continuous operation and minimal disruptions.

Application Field

Industrial Production Automation

In manufacturing plants, the GE SBI – PDP – 32 is extensively used for controlling and monitoring production lines. It can manage the operation of conveyors, robotic arms, and other manufacturing equipment. For example, it can precisely control the speed and movement of robotic arms to ensure accurate assembly of products, thereby improving production efficiency and product quality.

Mining and Energy

In the mining and energy sectors, this module is used to control and protect critical equipment. In a coal mine, it can monitor and control the operation of conveyor belts that transport coal, ensuring their safe and efficient operation. In power generation plants, it can be used to manage the control systems of turbines, helping to optimize power generation and prevent equipment failures.

Transportation

In the transportation industry, the GE SBI – PDP – 32 finds applications in areas such as railway signaling systems. It can control and monitor the signals, ensuring the safe and smooth movement of trains. In addition, it can be used in the automation systems of vehicle manufacturing plants, contributing to the efficient production of vehicles.

SBI-PDP-32

Related Products

- GE SBI – PDP – 16: Similar to the GE SBI – PDP – 32, but with 16 input channels instead of 32. It is a more cost – effective option for applications that do not require a large number of input channels.

- GE PLC – Series X: This is a series of programmable logic controllers by GE. The GE SBI – PDP – 32 can be integrated with these PLCs to enhance their functionality, providing additional logic control and data processing capabilities.

- Phoenix Contact Relay Modules: As the GE SBI – PDP – 32 is compatible with Phoenix Contact’s relays, these relay modules can be used in conjunction with it. They offer different voltage ratings and contact configurations to meet various industrial needs.

- Logic + Programming Software (Upgraded Version): An updated version of the software used to configure the GE SBI – PDP – 32. It may offer more advanced features, better user interfaces, and enhanced compatibility with the latest operating systems.

- GE Industrial Communication Modules: These modules can be used to expand the communication capabilities of the GE SBI – PDP – 32. They support additional communication protocols and can improve the module’s connectivity within complex industrial networks.

Installation and Maintenance

Pre – installation preparation: Before installing the GE SBI – PDP – 32, ensure that the installation environment meets the specified temperature and humidity requirements, ranging from – 40 °C to + 85 °C and 5% – 95% non – condensing respectively. Check the power supply to ensure it falls within the 9 – 30 VDC input voltage range. Verify the compatibility of the module with the existing system components, such as the PLC and other connected devices. Also, have the necessary installation tools on hand, and make sure the mounting location has enough space to accommodate the 15 x 10 x 5 cm module.

Maintenance recommendations: Regularly inspect the GE SBI – PDP – 32 for any signs of physical damage, such as cracks or loose connections. Monitor the operating temperature to ensure it remains within the specified range. Check the communication status with other devices to ensure seamless data transfer. If any issues arise, refer to the product manual for troubleshooting steps. Additionally, keep the module clean to prevent dust and debris from affecting its performance.

Product Guarantee

General Electric stands firmly behind the quality of the GE SBI – PDP – 32. The product is built to high – quality standards, ensuring reliable performance over an extended period. GE offers a comprehensive after – sales service, including technical support for installation, configuration, and troubleshooting. In case of any manufacturing defects, the company provides replacement or repair services within the warranty period. This commitment to quality and customer satisfaction reflects GE’s confidence in the GE SBI – PDP – 32 and its ability to meet the demands of industrial automation applications.