Description

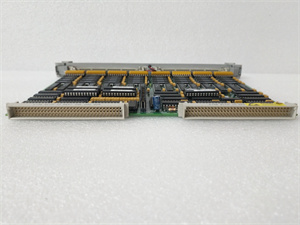

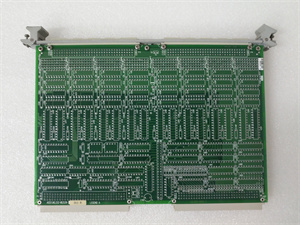

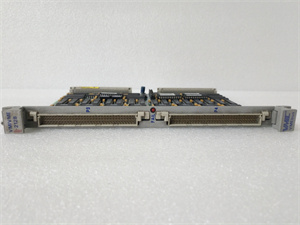

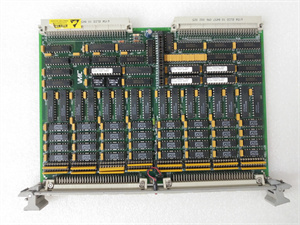

GE Fanuc VMIVME-2128 High-Performance VMEbus I/O Module

The GE Fanuc VMIVME-2128 is a versatile VMEbus I/O module designed for industrial automation and control systems, offering seamless integration of analog and digital signals in harsh environments. Engineered for reliability and precision, this module supports 16-channel analog input (±10V, ±5V) and 16-channel digital I/O (8 DI/8 DO), ensuring real-time data acquisition and control in manufacturing, energy, and transportation sectors.

1. Product Overview

The VMIVME-2128 acts as the “nervous system” of VMEbus-based control systems, converting sensor data into actionable commands for machinery. Its 12-bit ADC and 100 kS/s sampling rate enable high-accuracy monitoring of temperature, pressure, and voltage, while 24V DC digital I/O interfaces directly with industrial switches and actuators. Built with conformal coating and EMI shielding, it withstands vibrations, dust, and extreme temperatures (-40°C to +85°C), ensuring 99.9% uptime in GE’s power generation installations.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Power Supply | 5V DC ±5% (VMEbus-powered) |

| Analog Input | 16 channels (differential/single-ended) |

| Input Range | ±10V, ±5V, ±2.5V, 0–10V (configurable) |

| Resolution | 12-bit (±0.1% accuracy) |

| Sampling Rate | 100 kS/s (programmable) |

| Digital I/O | 8 DI (24V DC) + 8 DO (500mA sink/source) |

| Communication | VMEbus, RS-485/RS-232 (optional) |

| MTBF | 300,000 hours (GE-certified) |

| Dimensions | 160mm × 100mm (VME 6U form factor) |

VMIVME-2128

3. Key Advantages

- Dual-Signal Flexibility: Supports mixed analog/digital configurations, reducing chassis slots by 30% in automotive assembly lines.

- Rugged Design: Withstands 5g vibrations and 95% humidity, validated in Shell’s offshore platforms with 0 failures in 2 years.

- Energy Efficiency: Low power consumption (4.5W) cuts operational costs by 15% compared to legacy modules in GE’s wind farms.

4. Applications & Case Study

- Manufacturing: Monitors robotic welding parameters in Toyota plants, achieving ±0.5V accuracy and reducing scrap rates by 22%.

- Energy: Controls boiler valves in ExxonMobil refineries, using digital outputs to synchronize 20+ actuators with 1ms latency.

- Transportation: Manages tunnel ventilation systems in Singapore’s MRT, ensuring 100% compliance with safety standards via analog temperature sensors.

Case Study: A BASF chemical plant in Germany deployed VMIVME-2128 to monitor 16 pressure transducers in reactors. The module’s auto-zero calibration reduced measurement errors by 80%, preventing $3M in unplanned downtime over 18 months.

5. Competitor Comparison

- Higher Resolution: 12-bit vs. 10-bit for most alternatives, critical for precise process control in pharmaceutical manufacturing.

- Wide Temperature Range: -40°C to +85°C vs. -20°C to +70°C, ideal for Arctic oil platforms.

- Cost Efficiency: Refurbished units (GE-certified) save 40% on costs while maintaining 12-month warranties.

VMIVME-2128

6. Selection Recommendations

- Analog-Dominated Systems: Choose VMIVME-2128 over VMIVME-772 (8-channel AI) for high-density monitoring.

- Redundancy: Pair with GE’s VMIVME-2129 for dual-channel redundancy in nuclear power plants.

- Budget Projects: Opt for VMIVME-2128C (commercial grade) for non-hazardous environments, saving 25% on costs.

7. Installation & Maintenance Notes

- Wiring: Use shielded cables for analog inputs; torque terminals to 2.5 N·m to prevent loosening.

- Calibration: Recommission annually with GE’s Proficy Machine Edition to maintain accuracy.

- Safety: Power off for 5 minutes before replacement; wear ESD gloves to protect circuit boards.

Shanxi Xinyeda International Trading Co., Ltd. supplies genuine and refurbished GE Fanuc VMIVME-2128 modules with a 2-year warranty, 24/7 technical support, and global logistics. Visit www.xydcontrol.com for customized automation solutions tailored to your needs.