Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

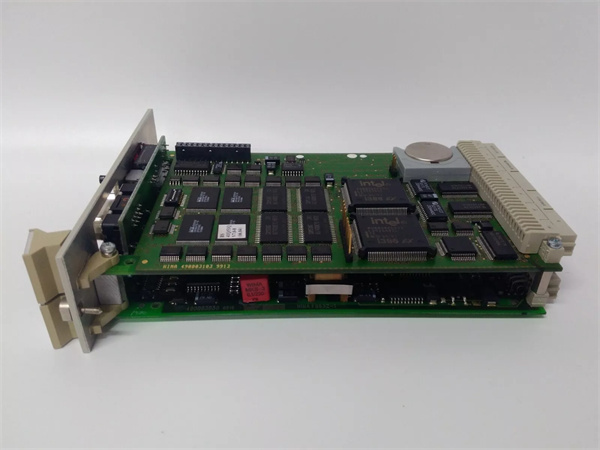

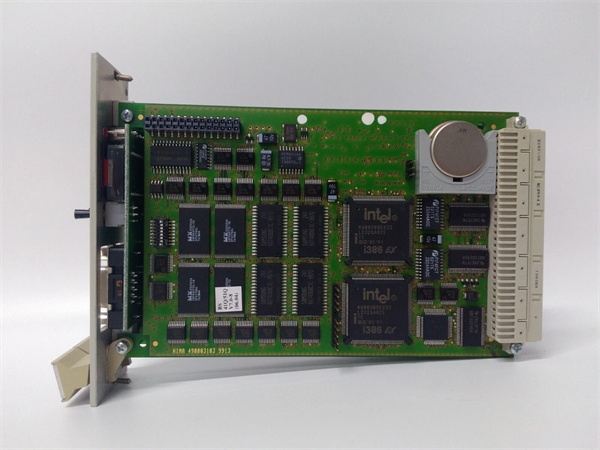

| Product Model | HIMA F8652E |

| Manufacturer | HIMA |

| Product Category | Safety CPU Module |

| Processor | Intel 386EX, 32-bit |

| Clock Frequency | 25 MHz |

| Memory | 1 MB Flash-EPROM (OS), 1 MB Flash-EPROM (User), 1 MB SRAM (Data) |

| Input Voltage | 24V DC ±15% |

| Communication Interfaces | Ethernet, RS-485, CANopen, Profibus DP |

| Operating Temperature Range | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% (non-condensing) |

| Dimensions | 100mm x 75mm x 20mm |

| Weight | 0.3 kg |

| Certifications | SIL 3 (IEC 61508), ATEX Ex ia IIC T6 |

HIMA 8652E

Product Introduction

The HIMA F8652E is a high-performance safety CPU module designed for critical safety applications. It is part of the HIQuad H41q/H51q safety controller series and is widely used in the process industry for reliable control and monitoring.

Core Advantages and Technical Highlights

High Safety Integrity Level

The HIMA F8652E is certified to SIL 3 (IEC 61508) and ATEX Ex ia IIC T6, making it suitable for high-risk applications.

Redundant Design

The module features dual Intel 386EX processors running in clock synchronization, ensuring high fault tolerance and system availability.

Comprehensive Diagnostics

It includes a four-digit alphanumeric display and LED indicators for detailed diagnostic information, simplifying on-site troubleshooting.

High-Speed Processing

The module supports a high sampling rate of 25 microseconds, ensuring rapid response to input changes and providing accurate detection data in real time.

Typical Application Scenarios

The HIMA F8652E is widely used in:

-

Oil and Gas: For emergency shutdown systems (ESD) and fire & gas detection systems.

-

Power Generation: For turbine overspeed protection and generator safety interlocks.

-

Chemical Processing: For controlling safety interlocks in reactors and storage tanks.

Related Model Recommendations

-

HIMA F8627: An Ethernet communication module for seamless integration.

-

HIMA F8621A: A coprocessor module for enhanced system performance.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation

Ensure the environment meets the specified temperature and humidity requirements. Use appropriate tools and safety equipment to secure the module in place. Connect the input and output cables according to the manufacturer’s guidelines.

Maintenance Suggestions

Regularly inspect the module for signs of wear or damage. Keep the unit clean and free from dust to prevent overheating and ensure efficient operation.