Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CC – MCAR01

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Carrier channel component

|

|

Electrical performance

|

Operating voltage: 24VDC (common, can be adapted to other voltages in some applications); Power consumption: Less than 6W (low – power design)

|

|

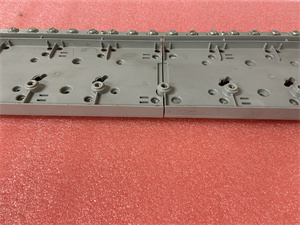

Physical size

|

Approximately 120mm×75mm×67mm (compact design for space – saving installation)

|

|

Interface type

|

Supports coaxial cable, twisted – pair cable and other transmission media interfaces

|

|

Communication protocol

|

Compatible with multiple industrial – standard protocols such as Profibus DP

|

|

Environmental requirements

|

Operating temperature range: – 20℃ – 70℃; Resistant to a certain degree of dust, humidity and electromagnetic interference

|

|

Installation method

|

Designed for easy installation in industrial control cabinets, with secure mounting options

|

|

Performance indicators

|

High – reliability design; Can achieve long – distance signal transmission, up to 10Mbps signal transmission rate (adjustable according to configuration); In Profibus DP network, it can connect up to 32 slave devices

|

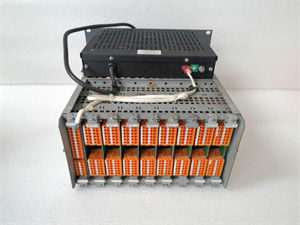

Honeywell CC-MCAR01

Product introduction

The Honeywell CC – MCAR01 is a carrier channel component developed by the renowned industrial automation giant, Honeywell. As a key part of industrial control systems, the CC – MCAR01 plays a crucial role in enabling seamless communication among various devices in industrial settings. It is designed to be integrated into a wide range of industrial automation platforms, facilitating the transmission of data between sensors, actuators, and controllers.

This component utilizes advanced carrier signal technology to modulate and transmit data. By doing so, it can effectively overcome the challenges of long – distance transmission and interference in industrial environments. In complex industrial systems, the CC – MCAR01 acts as a reliable data bridge, ensuring that real – time information can be accurately delivered, which is essential for the stable operation and precise control of industrial processes.

Core advantages and technical highlights

Reliable and stable

The CC – MCAR01 is engineered with high – quality materials and advanced circuit design, enabling it to operate stably in harsh industrial environments. Its excellent anti – interference ability can filter out various electromagnetic noises, ensuring that the signal transmission remains accurate and stable. For example, in factories with a large number of motors and electrical equipment, the CC – MCAR01 can still maintain reliable communication without being affected by electromagnetic interference.

Long – distance transmission

Equipped with advanced carrier signal technology, the CC – MCAR01 can achieve long – distance data transmission. In large – scale industrial plants where devices are widely distributed, it can transmit data over long distances without significant signal attenuation. This feature reduces the need for additional signal repeaters, simplifying the system structure and reducing costs.

Multiple isolation protection

To prevent interference signals from invading the system, the CC – MCAR01 is equipped with multiple isolation protection mechanisms. Electrical isolation is achieved through isolation transformers and opto – couplers, which not only improve the quality of signal transmission but also protect the internal circuit from damage caused by abnormal external voltages and currents, enhancing the overall safety and stability of the industrial control system.

Flexible configuration

In response to the diverse needs of different industrial applications, the CC – MCAR01 offers flexible configuration options. It supports a variety of transmission media, allowing users to choose according to actual wiring conditions, transmission distance, and anti – interference requirements. In addition, through the supporting configuration tools, users can customize parameters such as signal transmission rate, modulation method, and communication protocol to adapt to different industrial devices and control systems.

Honeywell CC-MCAR01

Typical application scenarios

In the manufacturing industry, especially in large – scale production lines such as automotive manufacturing and electronics manufacturing, the CC – MCAR01 is widely used. For example, in an automotive assembly line, it can connect various automated devices, such as robotic arms, conveyors, and inspection equipment. By transmitting real – time data between these devices and the central control system, it enables precise control of the production process, ensuring the accurate assembly of automotive parts and improving production efficiency and product quality.

In the power generation industry, whether it is a thermal power plant, hydropower plant, or wind power plant, the CC – MCAR01 is also an essential component. In a thermal power plant, it can connect sensors for monitoring parameters such as temperature, pressure, and flow rate of boilers, turbines, and generators, and transmit this data to the power monitoring system. The monitoring system can then issue control commands through the CC – MCAR01 to adjust the operation of relevant equipment, ensuring the stable and efficient operation of the power generation process.

In the chemical industry, where the production process is complex and requires precise control of multiple parameters, the CC – MCAR01 plays a vital role. It can connect sensors and control valves on reaction vessels, pipelines, and pumps to monitor and control key parameters such as temperature, pressure, flow rate, and chemical concentration in real – time. This helps to ensure that chemical reactions proceed under optimal conditions, improving product quality, production efficiency, and safety.

Related model recommendations

CC – MCAR02

Belongs to the same series as the CC – MCAR01. It may have some upgraded features in terms of performance, such as higher – speed data transmission or more powerful anti – interference capabilities. It can be considered as an upgrade option for applications with more demanding requirements.

FC – MCAR – 02

This is another input – focused module from Honeywell. If the application mainly requires high – performance data collection from various sensors, the FC – MCAR – 02 can be a better choice. It can work in conjunction with the CC – MCAR01 in a more complex industrial control system, with the CC – MCAR01 handling overall control and monitoring tasks, and the FC – MCAR – 02 specializing in input data acquisition.

CC – SCMB02

This module is more related to signal conditioning. It can be used in combination with the CC – MCAR01 to expand the capabilities of the overall control system. For example, the CC – SCMB02 can pre – process certain signals before they are input into the CC – MCAR01, improving the performance of the entire system.

CC – TCF901

It may have a specific focus on temperature – related control functions. In industrial processes where temperature control is crucial, the CC – TCF901 can be used together with the CC – MCAR01. The CC – MCAR01 manages the overall system control, while the CC – TCF901 is dedicated to precise temperature regulation, collaborating to ensure the smooth operation of the industrial process.

CC – TCNT01

This model may be related to time – based control or counting operations. When the industrial process requires accurate time – stamping of events or counting of specific occurrences, the CC – TCNT01 can be integrated with the CC – MCAR01. The CC – MCAR01 is responsible for general control tasks, and the CC – TCNT01 handles time – and count – related operations, complementing each other to meet the complex requirements of the industrial automation system.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – MCAR01, carefully check the installation environment. Ensure that the ambient temperature is within the specified range of – 20℃ to 70℃, and the humidity level is within the acceptable range. The installation area should be free from excessive dust and strong electromagnetic interference sources. Prepare the necessary installation tools, such as screwdrivers and pliers. Thoroughly inspect the module for any signs of damage during transportation. Follow the installation manual provided by Honeywell strictly when making physical connections, ensuring that the module is securely installed in the control cabinet. When connecting electrical wires, double – check the wiring diagrams to avoid incorrect connections that may cause malfunctions or safety hazards.

Maintenance suggestions

Regularly inspect the CC – MCAR01 for any physical damage, such as cracks or loose connections. Clean the module periodically with a soft, dry brush to remove dust accumulation, as dust can affect its performance. Monitor the operating temperature of the module. If overheating occurs, check the ventilation in the control cabinet. In case of abnormal behavior or error messages, refer to the troubleshooting guide in the product manual. When replacing components, always use genuine Honeywell spare parts to ensure the performance and reliability of the module. Keep the software and firmware of the module up – to – date by installing the latest updates provided by Honeywell, as these updates often include performance improvements and bug fixes.

Service and guarantee commitment

Honeywell provides a comprehensive service and guarantee for the CC – MCAR01. The module comes with a standard warranty that covers defects in materials and workmanship for a specified period. Honeywell’s global network of technical support teams is available around the clock. These teams are highly trained and experienced in handling industrial control products. They can provide assistance during installation, commissioning, and troubleshooting. Customers can contact the technical support team through multiple channels, such as email, phone, or online chat. Honeywell also offers regular software updates to optimize the performance of the module and keep it compatible with the latest industrial control technologies. If a product failure occurs within the warranty period, Honeywell will promptly provide free repair or replacement services, demonstrating its confidence in the product quality and its commitment to customer satisfaction.