Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CC – PAIH02

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

HART Analog Input Module

|

|

Electrical performance

|

Power supply: 24 VDC; Power capacity: 60W

|

|

Physical size

|

Compact design for easy installation in tight spaces

|

|

Interface type

|

Standardized interfaces for sensor connection

|

|

Communication protocol

|

Supports HART protocol

|

|

Environmental requirements

|

Can operate in a wide temperature range; Resistant to certain levels of dust and humidity

|

|

Installation method

|

DIN – rail mounting

|

|

Performance indicators

|

16 channels; Supports input types: 4 – 20 mA, 1 – 5 V, 0 – 5 V; Differential / single – ended input option

|

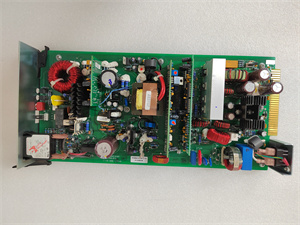

Honeywell CC-PAIH02

Product introduction

The Honeywell CC – PAIH02 is a high – performance HART analog input module, designed to play a pivotal role in industrial automation systems. As part of Honeywell’s comprehensive range of industrial control products, it is engineered to meet the demands of modern manufacturing and process control environments.

This module is responsible for receiving analog signals from an array of industrial sensors. These sensors could be measuring critical parameters such as temperature, pressure, or flow rate. Once the analog signals are received, the CC – PAIH02 converts them into digital signals that can be easily processed by Programmable Logic Controllers (PLCs) or Distributed Control Systems (DCS). By doing so, it enables real – time monitoring and precise control of industrial processes, ensuring smooth operations and high – quality output.

Core advantages and technical highlights

HART protocol support

The CC – PAIH02 stands out with its support for the HART protocol. This allows for two – way communication with HART – enabled smart instruments. It not only facilitates the transfer of analog data but also enables the configuration and diagnostics of these instruments. For example, in a large – scale industrial plant, operators can remotely access the status of sensors and make necessary adjustments, reducing the need for on – site inspections and maintenance time.

Multiple input channels

Featuring 16 channels, the module has the capacity to simultaneously connect to multiple sensors. This significantly increases data acquisition efficiency. In a complex industrial process where numerous parameters need to be monitored, such as in a chemical plant with multiple reaction vessels, the CC – PAIH02 can handle all the sensor inputs, providing a comprehensive view of the process in real – time.

Versatile input types

It is compatible with a wide range of analog input types, including 4 – 20 mA, 1 – 5 V, and 0 – 5 V. This versatility makes it suitable for use with various sensors commonly found in industrial settings. Whether it’s a current – outputting pressure sensor or a voltage – based temperature sensor, the CC – PAIH02 can accurately capture the signals, ensuring seamless integration with different types of industrial equipment.

Robust design

Engineered with a robust build, the CC – PAIH02 can withstand harsh industrial environments. It is resistant to temperature fluctuations, dust, and humidity, which are common in manufacturing plants, refineries, and power generation facilities. This durability ensures stable performance over an extended period, minimizing downtime and maintenance costs.

Honeywell CC-PAIH02

Typical application scenarios

Chemical industry

In chemical manufacturing, precise control of process parameters is crucial for product quality and safety. The CC – PAIH02 can be connected to sensors monitoring temperature, pressure, and chemical composition in reactors and pipelines. For instance, in a polymerization process, accurate temperature control is essential. The module’s ability to precisely convert analog signals from temperature sensors enables the DCS to adjust the cooling or heating systems in real – time, maintaining the optimal reaction conditions.

Power generation

Power plants, whether thermal, hydro, or wind, rely on accurate monitoring of various parameters. The CC – PAIH02 can be used to connect to sensors that measure steam temperature and pressure in thermal plants, water level and flow rate in hydro plants, or wind speed and direction in wind farms. The accurate data it provides helps in optimizing power generation efficiency, ensuring stable power supply, and preventing equipment failures.

Food and beverage industry

In food and beverage production, maintaining consistent quality is key. The module can be connected to sensors that monitor parameters such as liquid levels in tanks, temperature during pasteurization, and pressure in filling machines. By accurately converting these analog signals, it enables the control system to ensure that each product batch meets the required quality standards, reducing product waste and enhancing customer satisfaction.

Related model recommendations

CC – PAIH51

Belongs to the same series as the CC – PAIH02. It also supports the HART protocol but may have different channel configurations or performance specifications. For example, it could have a different number of input channels or higher – precision signal conversion capabilities, which can be considered for applications with more complex data – acquisition requirements.

CC – PAIN01

Another analog input module from Honeywell. While it shares the basic function of converting analog signals, it may lack the HART protocol support of the CC – PAIH02. It can be a more cost – effective alternative for applications where HART – enabled devices are not involved.

CC – PAIM01

Designed specifically for handling low – level analog signals, such as those from thermocouples and RTDs. If the application mainly focuses on temperature measurement using these types of sensors, the CC – PAIM01 may be more suitable than the CC – PAIH02, which is more versatile in handling a broader range of input types.

CC – PAOH01

An analog output module. It is used in combination with the CC – PAIH02 in industrial control systems. The CC – PAIH02 is responsible for gathering input data, and the CC – PAOH01 sends out control signals to actuators, such as valves and motors, based on the processed input data.

CC – PAOX01

Similar to the CC – PAOH01 as an analog output module, but with potentially different output channel configurations or performance characteristics. In applications where specific output requirements, like different current or voltage output ranges, are needed, the CC – PAOX01 could be a better choice when paired with the CC – PAIH02.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – PAIH02, ensure the installation environment meets the module’s requirements. The ambient temperature should be within the specified operating range, and the area should be relatively free of excessive dust and moisture. Gather the necessary installation tools, such as a screwdriver for DIN – rail mounting. Thoroughly inspect the module for any signs of damage during transportation. When making electrical connections, strictly follow the wiring diagrams provided in the product manual. Connect the 24 VDC power supply correctly and ensure proper grounding to protect against electrical malfunctions.

Maintenance suggestions

Regularly check the physical condition of the CC – PAIH02 for any signs of wear, corrosion, or loose connections. Dust accumulation can affect the module’s performance, so clean it periodically using a soft brush or compressed air. Monitor the input signals regularly to ensure they are within the expected range. In case of abnormal signals, refer to the troubleshooting guide in the product manual. If a component needs replacement, use only genuine Honeywell spare parts to maintain the module’s performance and reliability. Also, keep the control cabinet well – ventilated to help with heat dissipation.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the CC – PAIH02. The module comes with a standard warranty that covers defects in materials and workmanship for a specified period. Honeywell’s global network of technical support teams is available around the clock. They can provide assistance during installation, commissioning, and troubleshooting. In case of any issues, customers can reach out to these experts for guidance. The company also provides regular software updates to optimize the module’s performance and keep it compatible with the latest industrial control technologies. If a product failure occurs within the warranty period, Honeywell will promptly provide free repair or replacement services, demonstrating its confidence in the product’s quality and its commitment to customer satisfaction.