Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | CC-TAON01 |

| Manufacturer | Honeywell |

| Product category | Analog Output Module |

| Output channels | 8 isolated channels |

| Output type | Voltage (0–10V DC) or current (4–20mA, 0–20mA) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Update rate | Up to 1000 updates per second |

| Isolation | Galvanic isolation (1500V AC rms) |

| Power supply | 24V DC ±10%, 5W typical power consumption |

| Operating temperature | -20°C to +70°C |

| Installation method | DIN-rail mountable (35mm standard rail) |

| Dimensions (L×W×H) | [Insert verified dimensions, e.g., 100mm×80mm×60mm] |

| Weight | [Insert verified weight, e.g., 0.3kg] |

| Communication protocol | Modbus RTU/TCP, EtherNet/IP |

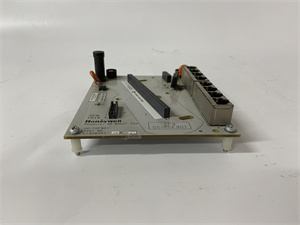

HONEYWELL CC-TAON01

Product introduction

The Honeywell CC-TAON01 is a high-performance analog output module designed to deliver precise control signals in industrial automation systems. As a key component of Honeywell’s Experion Process Knowledge System (PKS), this module bridges the gap between digital control systems and analog field devices, ensuring seamless translation of digital commands into reliable analog outputs.

Featuring 8 isolated channels, the CC-TAON01 supports both voltage and current output types, making it compatible with a wide range of actuators, valves, and drives. Each channel boasts a 16-bit resolution and ±0.1% accuracy, enabling fine-grained control over critical process variables such as flow rate, pressure, and temperature. For example, in a chemical reactor, the module can precisely adjust valve positions based on real-time control signals from a DCS, ensuring optimal reaction conditions. Its galvanic isolation (1500V AC rms) protects against electrical noise and ground loops, enhancing reliability in harsh industrial environments.

The CC-TAON01 is engineered for easy integration into complex automation networks. Its support for protocols like Modbus and EtherNet/IP allows seamless communication with PLCs, HMIs, and supervisory systems. Whether used in standalone applications or large-scale distributed systems, this module ensures stable, high-fidelity signal transmission, making it an indispensable asset for industries requiring precision and reliability.

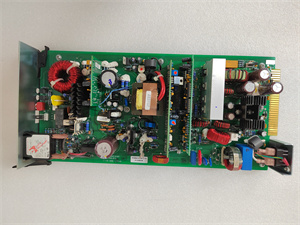

Core advantages and technical highlights

Ultra-precise control capabilities

The module’s 16-bit resolution and ±0.1% accuracy enable it to deliver highly granular analog signals, critical for applications where small deviations can impact product quality or process safety. For instance, in pharmaceutical manufacturing, the CC-TAON01 can accurately control the flow rate of sterile fluids into filling machines, ensuring dosage consistency and compliance with strict quality standards. Its high update rate (up to 1000 updates per second) allows for real-time adjustments, minimizing lag in responsive control loops.

Robust isolation and reliability

Galvanic isolation on each channel protects the module from electrical interference, the primary cause of signal degradation in industrial settings. This feature is particularly vital in environments with high-power equipment, such as steel mills or oil refineries, where electromagnetic interference (EMI) can disrupt control signals. The module’s rugged design, with an operating temperature range of -20°C to +70°C, ensures consistent performance in extreme conditions, reducing downtime and maintenance costs.

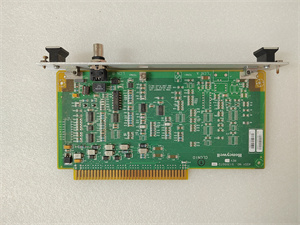

Flexible configuration and scalability

With configurable voltage and current outputs, the CC-TAON01 adapts to diverse field devices without requiring hardware modifications. Engineers can easily switch between output types via software, simplifying system design and reducing inventory complexity. The module’s DIN-rail mountable design allows for dense installation in control cabinets, making it suitable for space-constrained applications. For larger systems, multiple CC-TAON01 modules can be networked to support hundreds of output channels, providing scalable solutions for industrial plants of any size.

Advanced diagnostics and ease of use

Built-in diagnostics continuously monitor channel status, detecting faults such as open circuits or 超限 values. This proactive approach to maintenance enables quick troubleshooting and reduces mean time to repair (MTTR). The module’s plug-and-play compatibility with Honeywell’s Experion PKS and third-party systems streamlines commissioning, while intuitive configuration tools eliminate the need for specialized programming knowledge.

HONEYWELL CC-TAON01

Typical application scenarios

Oil and gas refining

In petroleum refineries, the CC-TAON01 controls critical processes such as distillation column pressure regulation and catalyst flow optimization. For example, it can send 4–20mA signals to control valves in a crude oil pre-heater, adjusting heat input to maintain optimal distillation temperatures. Its isolation features protect against voltage spikes from high-power pumps, ensuring stable operation in volatile refining environments.

Power generation

In thermal power plants, the module manages steam turbine speed by adjusting governor actuators via 0–10V signals. It also controls the feedwater flow rate to boilers, maintaining precise water levels to prevent overheating or shutdowns. In renewable energy applications, such as wind farms, the CC-TAON01 regulates pitch angles of turbine blades using analog signals, optimizing energy capture across varying wind speeds.

Food and beverage production

In bottling plants, the module ensures accurate filling levels by controlling piston pumps via analog current signals. For pasteurization systems, it adjusts temperature setpoints on heat exchangers, ensuring consistent product safety and quality. The CC-TAON01’s hygienic design (compatible with clean-in-place procedures) makes it suitable for food-grade environments, where contamination risks must be minimized.

Water treatment

In wastewater treatment facilities, the module controls the dosage of chemical additives (e.g., coagulants) by adjusting metering pump speeds. It also manages the opening of control valves in reverse osmosis systems, optimizing water purification efficiency. The module’s reliability in humid, corrosive environments ensures continuous operation in water treatment plants, even in harsh coastal or industrial settings.

Related model recommendations

CC-TAON02

An upgraded version with 16 output channels, ideal for high-density control applications. It shares the same protocol support and isolation features as the CC-TAON01 but offers double the channel capacity, suitable for large-scale manufacturing lines or utility plants.

CC-PAON01

A cost-optimized analog output module with 8 channels, designed for basic control tasks. It lacks some advanced diagnostics of the CC-TAON01 but provides reliable performance for small-to-medium systems, such as standalone packaging machines or HVAC systems.

CC-TAID01 (Analog Input Module)

Pairs with the CC-TAON01 to form a complete input/output loop. While the CC-TAON01 sends control signals to actuators, the CC-TAID01 captures feedback from sensors, enabling closed-loop control in applications like robotic assembly or chemical process control.

CC-TADM01 (Temperature Input Module)

Designed for direct connection to RTDs and thermocouples, this module complements the CC-TAON01 in temperature-centric applications, such as oven control or refrigeration systems. Together, they enable precise temperature sensing and actuation in a unified solution.

CC-TDOD51 (Digital Output Module)

Works alongside the CC-TAON01 to handle binary control tasks (e.g., motor starts/stops), while the CC-TAON01 manages analog-intensive functions. This combination is ideal for hybrid control systems, such as automated conveyor belts with both analog speed control and digital position sensing.

Installation, commissioning and maintenance instructions

Installation preparation

- Environment: Ensure the control cabinet meets IP20 standards for dust and moisture protection. Avoid installing near high-voltage cables to minimize EMI.

- Tools: Use screwdrivers for DIN-rail mounting and wire strippers for shielded cable termination.

- Safety: Power down the control system and verify zero voltage at the installation site before wiring.

- Wiring: Connect field devices using twisted-pair, shielded cables. Separate analog and digital wiring to prevent interference. Terminate ground wires securely to the module’s earth terminal.

Maintenance suggestions

- Daily checks: Monitor module status LEDs for fault indicators (e.g., red lights for channel errors).

- Periodic calibration: Use a multimeter to verify output accuracy against setpoints at least annually. Refer to Honeywell’s calibration guide for procedures.

- Troubleshooting: If a channel fails, first check wiring for loose connections or shorts. Use the module’s diagnostic software to identify faulty channels; replace individual channel cards (if hot-swappable) or the entire module as needed.

- Spare parts: Keep a replacement module on hand for critical systems. Ensure spare parts are stored in anti-static packaging and calibrated before deployment.

Service and guarantee commitment

Honeywell backs the CC-TAON01 with a 3-year warranty, covering defects in materials and workmanship. Customers gain access to 24/7 global technical support, including remote diagnostics and firmware updates. Honeywell’s network of certified service centers ensures rapid repair or replacement, minimizing downtime. For mission-critical applications, optional extended warranties and proactive maintenance plans are available, providing peace of mind and long-term performance assurance.