Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | CC – TAOX11 |

| Manufacturer | Honeywell |

| Product category | Analog Output Module |

| Output channels | 8 channels |

| Output signal types | 4 – 20mA, 0 – 20mA, 0 – 10V, -10V to +10V (configurable per channel) |

| Resolution | 16 – bit |

| Accuracy | ±0.05% of full scale |

| Settling time | <10ms for 90% step response |

| Isolation | 1500VAC rms channel – to – channel and channel – to – ground |

| Sampling rate | Up to 1000 samples per second per channel |

| Communication interface | Supports Modbus RTU/TCP, EtherNet/IP |

| Power supply | 24VDC ±10%, 6W maximum power consumption |

| Operating temperature range | -20°C to +70°C |

| Storage temperature range | -40°C to +85°C |

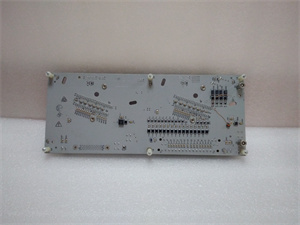

| Dimensions (L×W×H) | 105mm×115mm×75mm (4.13″×4.53″×2.95″) |

| Weight | 0.4kg (0.88lbs) |

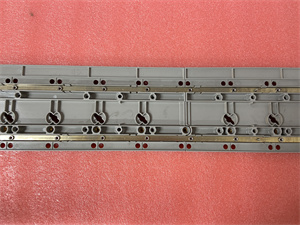

| Installation method | DIN – rail mountable (EN 50022) |

| Protection class | IP20 (front panel) |

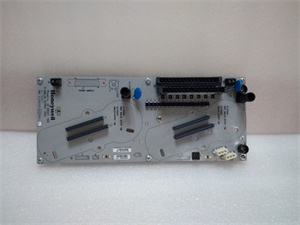

Honeywell CC-TAOX11

Product introduction

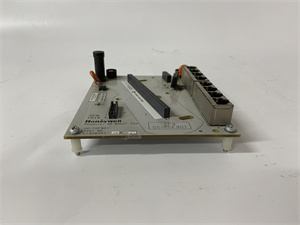

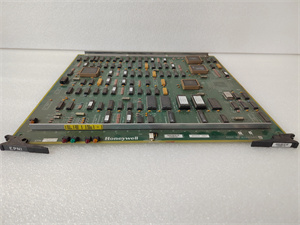

Honeywell, a global leader in industrial automation solutions, presents the Honeywell CC – TAOX11 analog output module as a cornerstone of its advanced control systems. Designed for seamless integration into the Experion Process Knowledge System (PKS) and other industrial control architectures, the CC – TAOX11 delivers precise analog control signals to a wide range of field devices.

This module serves as a critical interface between digital control systems and analog – based actuators, such as valves, drives, and regulators. With 8 independently configurable output channels, each offering 16 – bit resolution and an accuracy of ±0.05% of full scale, the CC – TAOX11 ensures highly accurate and repeatable control over industrial processes. Whether it’s regulating the flow of chemicals in a refining process, controlling the speed of a motor in a manufacturing line, or adjusting the temperature in a pharmaceutical reactor, the CC – TAOX11 provides the precision and reliability needed for demanding industrial applications.

Core advantages and technical highlights

High – precision output control

The CC – TAOX11 stands out with its exceptional output precision. The 16 – bit resolution allows for fine – grained control, while the ±0.05% accuracy ensures that the actual output closely matches the commanded value. This level of precision is crucial in applications where even small deviations can lead to significant quality issues or safety risks. For example, in semiconductor manufacturing, precise control of gas flow rates is essential for maintaining the integrity of the fabrication process.

Flexible signal configuration

Each channel of the CC – TAOX11 can be independently configured to support different signal types (4 – 20mA, 0 – 20mA, 0 – 10V, -10V to +10V). This flexibility makes the module suitable for interfacing with a wide variety of field devices, eliminating the need for multiple specialized modules. System integrators can easily adapt the module to different application requirements, reducing complexity and cost.

Robust isolation and reliability

The module features 1500VAC rms isolation between channels and from channels to ground. This isolation protects against electrical interference and ground loops, which are common sources of signal distortion in industrial environments. The CC – TAOX11 is also designed to operate reliably in harsh conditions, with an operating temperature range of -20°C to +70°C and a storage temperature range of -40°C to +85°C. These features ensure consistent performance and minimize downtime in critical industrial applications.

Fast response time

With a settling time of less than 10ms for a 90% step response, the CC – TAOX11 can quickly adjust to changing control requirements. This fast response is essential in applications that require rapid adjustments, such as in feedback control loops where real – time adjustments are needed to maintain process stability.

Advanced diagnostic capabilities

The CC – TAOX11 includes comprehensive diagnostic features that enable proactive monitoring of module health. It can detect faults such as open circuits, short circuits, and out – of – range conditions, and provide real – time alerts. These diagnostics help reduce maintenance time and improve system availability by allowing operators to address issues before they escalate.

Honeywell CC-TAOX11

Typical application scenarios

Oil and gas industry

In oil and gas refining processes, the CC – TAOX11 is used to control the opening and closing of control valves in pipelines. By precisely regulating the flow of oil, gas, and other fluids, the module helps maintain optimal process conditions and ensures safe and efficient operation. It is also used in controlling the pressure in distillation columns and other processing equipment.

Power generation

In power plants, the CC – TAOX11 plays a vital role in controlling the speed and output of generators. It adjusts the governor valves to regulate the flow of steam or water to the turbines, ensuring stable power generation. The module is also used in controlling the temperature and pressure in boilers and other power plant components.

Chemical manufacturing

In chemical manufacturing, precise control of process variables is critical for product quality and safety. The CC – TAOX11 is used to control the flow of reactants, the temperature in reactors, and the pressure in various stages of the manufacturing process. For example, it can accurately control the addition of catalysts to a reaction, ensuring that the chemical reaction proceeds as desired.

Water and wastewater treatment

In water and wastewater treatment plants, the CC – TAOX11 is used to control the dosage of chemicals such as disinfectants and coagulants. It also regulates the flow of water through various treatment processes, ensuring efficient and effective treatment. Additionally, the module is used in controlling the operation of pumps and other equipment in the treatment plant.

Related model recommendations

CC – TAOX01

This is a predecessor model to the CC – TAOX11. It has similar functionality but with a lower accuracy of ±0.1% of full scale. The CC – TAOX01 is suitable for applications where the highest level of precision is not required, offering a more cost – effective solution for less critical processes.

CC – TAON01

Another related analog output module, the CC – TAON01 has 8 output channels but with a different communication interface configuration. It is designed for applications that require specific communication protocols or integration with different control systems. The CC – TAON01 may be a better choice for systems that already use its particular communication interface.

CC – TAID01

This is an analog input module from Honeywell. While the CC – TAOX11 is used for output control, the CC – TAID01 is used for acquiring analog input signals from sensors. Together, they form a complete analog I/O solution for industrial control systems, allowing for both the measurement of process variables and the control of actuators based on those measurements.

CC – PDOD51

A digital output module, the CC – PDOD51 is used for controlling digital devices such as relays and solenoids. In industrial control systems, it often works alongside the CC – TAOX11 to provide a comprehensive control solution. The CC – PDOD51 handles digital control tasks, while the CC – TAOX11 manages analog control requirements.

CC – TAIN01

This is an analog input base module that can be used in conjunction with the CC – TAOX11. The CC – TAIN01 provides the physical platform and communication interface for multiple analog input modules. By combining the CC – TAOX11 with the CC – TAIN01 and other compatible modules, users can build a scalable and flexible industrial control system.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – TAOX11, ensure that the installation environment meets the specified requirements. The area should be clean, dry, and well – ventilated, with a temperature within the operating range of -20°C to +70°C. Gather the necessary tools, including a screwdriver for mounting the module on the DIN rail and wire strippers for making electrical connections.

Carefully inspect the module for any damage that may have occurred during shipping. Check the pin connections and ensure that the module is free of any debris. Mount the module securely on the DIN rail according to the manufacturer’s instructions. Make sure the module is properly seated and locked in place to prevent vibration – induced damage.

When making electrical connections, follow the wiring diagram provided in the product manual. Use appropriate gauge wires and ensure that all connections are tight and secure. Properly ground the module to prevent electrical interference and ensure safety.

Maintenance suggestions

Regular maintenance of the CC – TAOX11 is essential to ensure its continued reliable operation. Periodically inspect the module for signs of physical damage, such as cracks or loose connections. Check the wiring for any signs of wear or corrosion and replace any damaged wires.

Use the module’s diagnostic capabilities to monitor its performance and detect any potential issues. Regularly check the output signals to ensure they are within the expected range. If any faults are detected, refer to the troubleshooting section of the product manual to identify and resolve the issue.

Keep the module clean by removing any dust or debris that may accumulate on its surface. Use a soft, dry cloth for cleaning. Avoid using harsh chemicals or abrasive materials that could damage the module.

If replacement parts are required, always use genuine Honeywell components. Follow the manufacturer’s instructions for replacing parts to ensure proper installation and avoid voiding the warranty.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee commitment for the CC – TAOX11. The module is backed by a standard warranty that covers defects in materials and workmanship for a specified period. Honeywell’s global network of technical support teams is available to provide assistance with installation, commissioning, and troubleshooting.

Customers can also take advantage of Honeywell’s preventive maintenance services, which include regular inspections and testing to identify and address potential issues before they cause system failures. Honeywell offers software updates and enhancements to ensure that the CC – TAOX11 continues to perform at its best throughout its lifecycle.

In addition, Honeywell provides training programs to help customers’ personnel gain the knowledge and skills needed to effectively operate and maintain the CC – TAOX11. This commitment to service and support ensures that customers can rely on the CC – TAOX11 for their critical industrial control applications.