Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

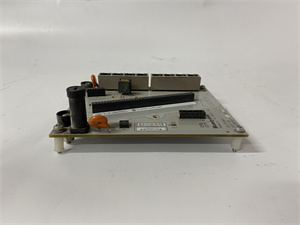

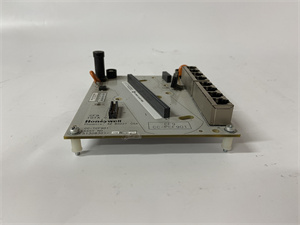

| Product model | CC – TCF901 |

| Manufacturer | Honeywell |

| Product category | Control Firewall Module |

| Electrical performance | Operating voltage: 12VDC; Output frequency: 50kHz |

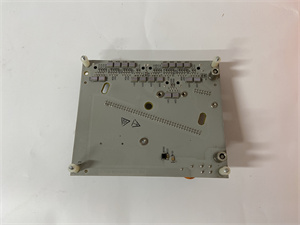

| Physical size | Approx. installation size (LxW): 12.1cm x 14.5cm |

| Interface type | 9 RJ – 45 Ethernet connections |

| Communication protocol | Supports TCP/IP, UDP, ICMP, HTTP, HTTPS, etc. |

| Environmental requirements | Operating temperature: -20°C to +55°C; Humidity: 0% – 95%RH (non – condensing) |

| Installation method | DIN – rail mountable |

| Performance indicators | Encryption algorithms: AES, DES, 3DES; Packet filtering rate: 50,000 packets/second; Customizable firewall rules |

| Configuration interface | Web – based management interface |

| Power supply | Built – in power supply with over – voltage protection |

CC-TCF901

Product introduction

The Honeywell CC – TCF901 is a 9 – port control firewall module, a crucial component in industrial control applications. It is designed to safeguard industrial networks and ensure seamless data communication. As part of Honeywell’s advanced automation solutions, the CC – TCF901 plays a dual role as a security guardian and a connection bridge in industrial network architectures.

This module acts as an interface between digital control systems and various field devices. It is capable of receiving input signals from sensors, such as analog and digital signals, and converting them into a format understandable by the control system. Conversely, it takes the output signals from the controller and transforms them into signals suitable for actuators. In industrial automation systems, the CC – TCF901 is essential for maintaining the integrity of data flow and ensuring the secure operation of the overall system.

Core advantages and technical highlights

Exceptional security protection

The CC – TCF901 employs deep – packet inspection technology. It can not only examine the header information of network packets but also analyze the data content within. This enables it to accurately identify and block malicious software, viruses, and various network attacks that disguise as normal communication. For example, it can detect and prevent DDoS attacks and SQL injection attacks targeted at industrial control systems. Additionally, it has an advanced intrusion detection and prevention system (IDS/IPS). This system continuously monitors network traffic for abnormal behavior and attack signatures. Once a potential threat is detected, it immediately takes response measures, such as blocking connections and sending alerts to administrators, minimizing the impact of network attacks on industrial production.

Strong network connection and integration

With 9 ports, the CC – TCF901 can simultaneously connect multiple industrial devices of different types. In large – scale industrial automation production lines, it can link sensors, controllers, and actuators distributed in different areas, enabling seamless data sharing and collaborative work among these devices. Its wide support for multiple network protocols allows it to be easily integrated into existing industrial network architectures, whether traditional industrial Ethernet or emerging industrial wireless networks. This provides great convenience for enterprises during network upgrades or expansions, as new and old systems can be integrated without the need for large – scale replacement of network equipment.

High reliability and stability

Designed to meet strict industrial – grade standards, the CC – TCF901 uses high – quality electronic components, providing excellent resistance to electromagnetic interference (EMI) and radio – frequency interference (RFI). This ensures stable operation even in complex electromagnetic environments, such as in steel and power plants. It also supports redundant configurations, like power redundancy and link redundancy. In the event of a failure in the main power supply or communication link, the backup can switch over seamlessly, preventing industrial production from being interrupted due to single – point failures and enhancing the availability and stability of industrial control systems.

CC-TCF901

Typical application scenarios

Oil and gas industry

In the oil and gas industry, the CC – TCF901 is used to connect sensors and control systems in oil refineries and gas processing plants. It securely transmits real – time data such as temperature, pressure, and flow rate from sensors to the central control system for analysis and decision – making. Its powerful security features protect against external network attacks, preventing production data from being leaked or tampered with. For instance, in a refinery’s distillation unit, the CC – TCF901 ensures accurate data transmission from sensors to the control system while guarding against hacker attacks on the control system, thus avoiding significant economic losses due to production disruptions.

Power generation

In power generation, especially in smart grids, the CC – TCF901 is a key component for ensuring communication security. It connects devices in substations, power plants, and distribution networks, enabling high – speed and secure transmission of power data. In a substation, it safeguards the communication between monitoring systems and devices like smart meters and protection devices, preventing power failures or blackouts caused by network attacks and ensuring the reliable operation of the power grid.

Manufacturing

On manufacturing automation production lines, the CC – TCF901 connects robots, automated equipment, and sensors to form an efficient industrial network. By collecting and transmitting production data in real – time, it enables precise control and optimization of the production process. In an automotive manufacturing plant’s welding line, the CC – TCF901 ensures stable communication between robots and controllers. It also prevents external network attacks from interfering with the production line, improving production efficiency and product quality.

Related model recommendations

- CC – PCF901: Similar to the CC – TCF901, it is also a control – related module from Honeywell. It has a modular design and is suitable for integration into control system architectures, but may have different 侧重点 in terms of functionality, such as a different set of supported protocols or a different number of I/O channels.

- CC – TAOX11: This is an analog output module by Honeywell. While the CC – TCF901 focuses on network security and connection, the CC – TAOX11 is mainly used for providing analog output signals to control field devices, like valves and drives, and can be used in combination with the CC – TCF901 in a comprehensive industrial control system.

- CC – PAIH01: An analog input card that supports the HART protocol. It can be used in tandem with the CC – TCF901 as part of an industrial control system. The CC – PAIH01 is responsible for collecting analog input signals from sensors, and the CC – TCF901 manages the network security and data transmission related to these signals.

- CC – PDIL01: A digital input card for 24VDC. It complements the CC – TCF901 in an industrial control setup. The CC – PDIL01 receives digital input signals from devices in the field, and the CC – TCF901 ensures the secure transfer of these signals within the network.

- CC – PDOB01: A digital output card (24VDC). It can work with the CC – TCF901 in an industrial system. The CC – TCF901 manages the network side, and the CC – PDOB01 is used to output digital control signals to actuators and other devices in the field.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – TCF901, select a well – ventilated, dry location with a temperature between -20°C and +55°C. Avoid areas near strong electromagnetic interference sources, such as large motors or transformers. Gather the necessary tools, including a screwdriver for DIN – rail mounting and wire strippers for electrical connections. Carefully inspect the module for any shipping – related damage. Mount the module firmly on the DIN rail according to the provided instructions. Ensure all electrical connections, including the 12VDC power supply and Ethernet cables, are correctly and tightly connected, following the wiring diagram.

Maintenance suggestions

Regularly check the physical appearance of the CC – TCF901 for signs of damage or overheating. Monitor network connections through the management interface, ensuring stable data transmission. Keep an eye on the power supply for any voltage fluctuations. Stay updated on Honeywell’s official security updates and firmware upgrades for the module. Install these updates in a timely manner to address security vulnerabilities and improve performance. When troubleshooting, first refer to the system logs in the management interface to identify the root cause of any issues. For network connection problems, check for loose cables or damaged interfaces. If the issue persists, contact Honeywell’s technical support for further assistance.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the CC – TCF901. The module comes with a standard warranty covering defects in materials and workmanship. Honeywell’s global technical support teams are available around the clock to assist with installation, commissioning, and troubleshooting. They can provide remote guidance or, if necessary, dispatch on – site technicians. In addition, Honeywell offers preventive maintenance services, which include regular inspections and performance testing. This helps identify potential issues before they lead to system failures. The company is committed to providing software updates to keep the CC – TCF901 up – to – date with the latest security features and functionality improvements, ensuring its long – term reliable operation for customers.