Description

1. Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CC – TDOB11

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Redundant Digital Output Module

|

|

Electrical performance

|

Input voltage: Nominal 24V DC, range 21.6 – 30V DCOutput voltage (source): Nominal 24V DC, range 21.6 – 30V DC; Output voltage (sink): 0V DCOutput current (source): 0.5A per channel; Output current (sink): 3A per channelIsolation: 1500V per channel

|

|

Physical size

|

Dimensions: 85×50×22mmWeight: 0.38kg

|

|

Interface type

|

Interface points suitable for connecting field devices

|

|

Communication protocol

|

Not explicitly specified in main sources, but interfaces with relevant control systems for data transfer

|

|

Environmental requirements

|

Operating temperature: – 40°C to 70°CStorage temperature: – 55°C to 85°CHumidity: 0 – 95% non – condensingVibration: 2g rms, 10 – 500HzShock: 30g, 11ms pulseProtection level: IP67

|

|

Installation method

|

Designed for easy installation, can be flexibly integrated into various industrial control cabinets

|

|

Performance indicators

|

Output channels: 8 isolated, redundant digital output channels

|

|

Current draw

|

Not specified in main sources

|

|

Heat dissipation

|

Not specified in main sources

|

Honeywell CC-TDOB11

2. Product introduction

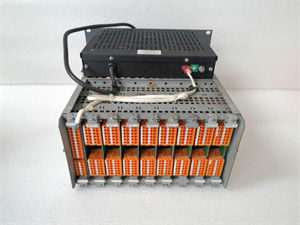

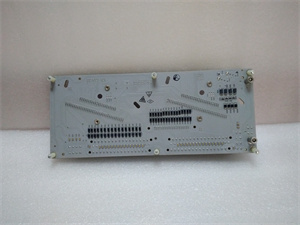

The Honeywell CC – TDOB11 is a high – performance redundant digital output module, which is an integral part of the Honeywell Experion Process Knowledge System (PKS) Series C. Engineered for critical industrial applications, this module plays a pivotal role in industrial automation systems.

Its core function is to accurately convert digital signals from control systems into signals that can drive field devices. By doing so, it enables the seamless operation of actuators such as relays, motors, and solenoid valves in industrial processes. In the context of the Experion PKS Series C platform, the CC – TDOB11 is designed to work in harmony with other components of the system, providing reliable digital output control. It serves as a crucial link between the control center and the actual equipment in the field, ensuring that control commands are effectively executed, and thus maintaining the stability and efficiency of the overall industrial automation system.

3. Core advantages and technical highlights

Redundant design for unrivaled reliability

The Honeywell CC – TDOB11 features a redundant architecture. This means that within the module, there are backup signal transmission and processing paths. In the event of a failure in the primary channel, the backup channel can switch over instantaneously and seamlessly. This ensures that the output signals remain uninterrupted, minimizing the risk of production disruptions. For industries where continuous operation is non – negotiable, like oil refineries and power plants, this redundant design is invaluable, safeguarding against potential losses due to system failures.

Exceptional isolation and robust load – driving capacity

With 1500V of isolation per channel, the CC – TDOB11 is highly resistant to electrical interference. In the complex electromagnetic environments typical of industrial settings, such as steel mills or large – scale manufacturing plants, this isolation effectively shields the output signals from external interference, preventing misoperation of equipment. Additionally, it has a strong load – driving capacity, with an output current (source) of 0.5A per channel and an output current (sink) of 3A per channel. This allows it to effortlessly connect and drive a wide range of industrial actuators, meeting the diverse needs of different industrial applications.

Advanced diagnostics and user – friendly maintenance

Equipped with advanced internal diagnostic capabilities, the CC – TDOB11 can continuously monitor its own operating status. As soon as it detects any anomalies, such as signal transmission errors or hardware malfunctions, it promptly reports the fault information to the control system via indicator lights or communication interfaces. This significantly reduces the time required for maintenance personnel to troubleshoot problems, minimizing equipment downtime. Moreover, the module supports hot – swapping, enabling replacement of faulty modules without shutting down the entire system, which greatly enhances system maintainability and uptime.

Compact design for space – constrained applications

Despite its high – performance capabilities, the CC – TDOB11 is designed with a compact footprint, measuring only 85×50×22mm and weighing 0.38kg. This compact design makes it suitable for installation in control cabinets with limited space, such as those in small – scale industrial production lines or distributed control systems in the field. It offers a space – efficient solution without sacrificing on performance or functionality.

4. Typical application scenarios

Oil and gas industry

In the oil and gas sector, the Honeywell CC – TDOB11 is extensively used. For example, in oil drilling platforms, it controls various electric valves, precisely regulating the flow and pressure of pipelines during the crude oil extraction process. In gas processing plants, it drives the start – stop control of large compressors, ensuring the stable and efficient operation of natural gas purification and transportation. Given the complex and harsh production environments in this industry, along with the high demand for continuous production, the high – reliability and redundancy features of the CC – TDOB11 are perfectly suited to meet these stringent requirements.

Power industry

Whether in thermal, hydro, or wind power generation plants, the CC – TDOB11 plays a crucial role. In thermal power plants, it controls the actuators of boiler combustion systems, such as damper actuators and coal feeder motors, ensuring stable boiler combustion and improved power generation efficiency. In wind farms, it is used to control the yaw and pitch systems of wind turbines, enabling the turbines to adjust their positions according to wind direction and speed, thereby maximizing power generation. The power industry’s strict requirements for stable and reliable equipment operation are well – met by the CC – TDOB11‘s outstanding performance.

Chemical industry

Chemical production processes involve numerous complex chemical reactions and technological processes, demanding high – precision and reliable equipment control. The CC – TDOB11 is used to control the start – stop and speed regulation of agitator motors in chemical reactors, as well as the opening and closing of valves for material transfer and chemical reagent addition. In hazardous chemical production areas, where safety is of utmost importance, the CC – TDOB11‘s high – isolation performance and redundant design effectively prevent electrical failures from triggering safety accidents, ensuring the safe and stable operation of chemical production processes.

Honeywell CC-TDOB11

5. Related model recommendations

CC – TDOB01

This is a non – redundant version of the CC – TDOB11. It is more basic in function and lacks the redundant design. It is suitable for industrial scenarios where system cost is a major concern and the tolerance for equipment failure is relatively high. For instance, in some small – scale light industrial production lines, the CC – TDOB01 can meet the basic control needs while effectively reducing system costs.

CC – PDOB01

Another digital output module, the CC – PDOB01 may differ from the CC – TDOB11 in output characteristics and application scenarios. It might have different numbers of output channels or different output voltage/current specifications. It is applicable to industrial control systems with specific requirements for output channels or voltage/current, such as automated warehousing control systems with high demands for the number of output channels and specific voltage requirements.

CC – TDIL01

As a digital input module, the CC – TDIL01 complements the CC – TDOB11. The CC – TDIL01 is responsible for collecting digital input signals from field devices, such as sensor switch signals and equipment status feedback signals, and transmitting them to the control system. The CC – TDOB11, on the other hand, outputs digital control signals based on the control system’s instructions. In a complete industrial automation control system, they often work together to achieve comprehensive monitoring and control of industrial production processes.

CC – TAON01

Likely an analog output module, the CC – TAON01 has a different function from the digital output CC – TDOB11. In some industrial systems that require both digital and analog output capabilities, the CC – TDOB11 can handle digital – based control tasks, such as equipment start – stop control. Meanwhile, the CC – TAON01 can be used to output analog signals for fine – tuning equipment operating parameters, like adjusting the speed of motors or the opening degree of valves.

CC – PAIM01

This model may be involved in more complex control functions, perhaps related to process control algorithms. The CC – TDOB11 provides basic digital output functionality, while the CC – PAIM01 can utilize the output data from the CC – TDOB11 to perform advanced control operations. In an industrial process control system, they can cooperate to achieve more sophisticated control strategies, with the CC – TDOB11 as the executor of control signals and the CC – PAIM01 for processing and decision – making based on overall system requirements.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – TDOB11, choose a dry, clean, and well – ventilated installation environment. Ensure that the ambient temperature is within the specified operating range of – 40°C to 70°C. Prepare essential installation tools, such as screwdrivers and wrenches. Thoroughly inspect the module’s appearance for any signs of damage during transportation and check that all interfaces are free of deformation or foreign objects. When installing, strictly follow the wiring diagram in the product installation manual. Connect the 24V DC power supply correctly, paying close attention to the correct polarity. All connection cables to field devices should be firmly fastened to prevent loose connections that could lead to signal transmission problems or contact – related failures.

Maintenance suggestions

Regularly conduct visual inspections of the CC – TDOB11 to check for dust accumulation, component aging, or loose cables. Dust can affect the module’s heat dissipation and electrical performance, so use a clean brush or compressed air to clean it regularly. Perform signal detection at least once a month. Send different output commands to the module through the control system and check whether the output signals of each channel are accurate. Test the module’s redundant function quarterly by simulating a primary channel failure to ensure that the backup channel can switch over promptly and output correct signals. If any malfunctions or performance degradation are detected, contact Honeywell’s professional technical support in a timely manner and use original spare parts for replacement to maintain the module’s performance and reliability.

7. Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the Honeywell CC – TDOB11. The module comes with a standard 12 – month warranty. During this period, if the module fails due to material or manufacturing defects, Honeywell will provide free repair or replacement services. Honeywell’s global team of professional technical support is available 24/7. Whether it’s assistance during installation and commissioning or troubleshooting complex problems, customers can reach out to the support team at any time. Additionally, Honeywell continuously monitors industry – wide technological advancements and provides regular software updates and product upgrades. This ensures that the CC – TDOB11 remains at the forefront of performance in evolving industrial application environments, instilling confidence in customers when integrating it into their critical industrial control systems.