Description

1. Detailed Parameter Table

**

|

Parameter name

|

Parameter value

|

|

Product model

|

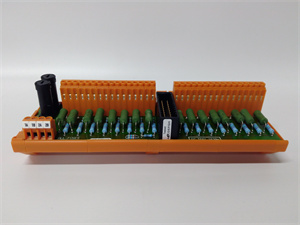

FC – TSAI – 1620M

|

|

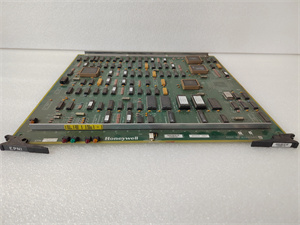

Manufacturer

|

Honeywell

|

|

Product category

|

Safety Analog Input Field Termination Assembly (FTA) Module

|

|

Input channels

|

16 (divided into 2 groups of 8 channels with common 0V)

|

|

Input voltage range

|

0 – 10V DC, 4 – 20mA, – 10V to 10V, – 20mA to 20mA

|

|

Input impedance

|

10MΩ

|

|

Input current

|

0 – 25mA

|

|

Input resistance

|

250Ω (±1%)

|

|

Output voltage to SAI – 1620M module

|

0 – 4V DC

|

|

Accuracy

|

0.10%

|

|

Linearity

|

±0.05%

|

|

Power supply

|

External 30V DC, 3mA (without input loop loads)

|

|

Fuse rating

|

315mA, 5x20mm, AC 125V, max. output current per fuse 220mA

|

|

Operating temperature range

|

– 40°C to 70°C

|

|

Storage temperature range

|

– 40°C to 85°C

|

|

Humidity range

|

5% to 95% RH (non – condensing)

|

|

Module dimensions

|

210×70×60mm (8.26×2.76×2.36 inches)

|

|

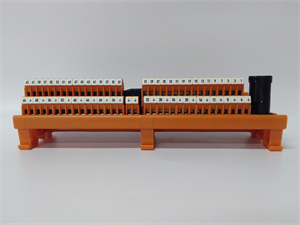

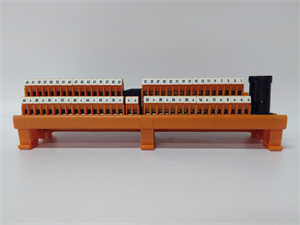

DIN EN rail compatibility

|

TS32 / TS35 x 7.5, used rail length 211mm (8.30 inches)

|

|

Weight

|

0.43kg

|

|

Termination type

|

Screw terminals, max. wire diameter 2.5mm² (AWG 14), strip length 7mm (0.28 inches), tightening torque 0.5Nm (0.37ft – lb)

|

|

Certifications

|

CE, TUV, UL, CSA, FM

|

Honeywell FC-TSAI-1620M

2. Product Introduction

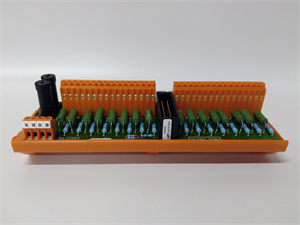

The Honeywell FC – TSAI – 1620M is a Safety Analog Input Field Termination Assembly (FTA) module, an integral part of industrial automation systems. As a product from the renowned brand Honeywell, the FC – TSAI – 1620M is designed with high – end technology and quality in mind.

This module serves as a critical interface between field components such as sensors and the high – density analog input module SAI – 1620M in safety manager systems. It can handle a wide variety of analog input signals, including those from temperature, pressure, and flow sensors. By converting these analog signals into a format suitable for the SAI – 1620M module, the FC – TSAI – 1620M enables the accurate monitoring and control of industrial processes. It plays a vital role in ensuring the safety and efficiency of industrial operations, especially in hazardous locations, as it is designed for use in Class I, Division 2 environments.

3. Core Advantages and Technical Highlights

High – accuracy Signal Processing

The Honeywell FC – TSAI – 1620M offers an accuracy of 0.10% and a linearity of ±0.05%, ensuring precise conversion of analog signals. This high – level accuracy is crucial for applications where even the slightest deviation can lead to significant operational issues. For example, in a chemical plant, accurate measurement of pressure and temperature is essential for maintaining the correct reaction conditions.

Wide Input Range Compatibility

With its ability to handle multiple input voltage and current ranges, including 0 – 10V DC, 4 – 20mA, – 10V to 10V, and – 20mA to 20mA, the FC – TSAI – 1620M is highly versatile. It can interface with a broad spectrum of sensors, making it suitable for diverse industrial applications. Whether it’s a flow sensor in an oil pipeline or a temperature sensor in a power generation plant, the module can effectively process the incoming signals.

Robust Construction for Harsh Environments

Built to withstand harsh environmental conditions, the module has an operating temperature range from – 40°C to 70°C and can tolerate humidity levels between 5% to 95% RH (non – condensing). Its rugged construction, along with multiple certifications like CE, TUV, UL, CSA, and FM, makes it reliable for use in challenging industrial settings such as oil and gas refineries, where extreme temperatures and potentially explosive atmospheres are common.

Easy Installation and Maintenance

The FC – TSAI – 1620M features screw terminals with clear specifications for wire diameter and tightening torque, simplifying the wiring process. Its compatibility with standard DIN EN rails (TS32 / TS35 x 7.5) allows for quick and easy installation. In case of maintenance, the module’s design enables straightforward troubleshooting, and the availability of replacement parts further ensures minimal downtime.

Honeywell FC-TSAI-1620M

4. Typical Application Scenarios

Oil and Gas Industry

In oil extraction, the Honeywell FC – TSAI – 1620M connects to pressure sensors in oil wells. By accurately converting the analog pressure signals to digital data for the safety manager system, it helps in monitoring well integrity. In gas pipelines, it interfaces with flow sensors, providing real – time data on gas flow rates. This is crucial for preventing leaks and ensuring the efficient transportation of gas.

Power Generation

For power plants, the module plays a significant role in monitoring the performance of generators. It connects to temperature sensors on generator windings and vibration sensors on turbine shafts. The accurate signal conversion by the FC – TSAI – 1620M allows the power plant’s control system to detect any abnormal conditions early, such as overheating or excessive vibration, helping to prevent equipment failures and ensure stable power supply.

Chemical Manufacturing

In chemical reactors, precise control of temperature, pressure, and chemical flow rates is essential. The FC – TSAI – 1620M connects to various sensors in the reactor system. For instance, it converts the analog signals from pressure sensors to ensure that the reactor operates within safe pressure limits. In case of any deviation, the safety manager system can take immediate corrective actions, such as adjusting the feed rates of reactants or activating safety valves.

5. Related Model Recommendations

Honeywell FC – TSAI – 810M

This model likely has fewer input channels (e.g., 8 channels), making it more suitable for smaller – scale industrial applications where cost – effectiveness and simplicity are key. It still retains the core functionality of analog signal conversion but in a more compact and less resource – intensive package.

Honeywell FC – TSAI – 1620H

The “H” in the model might indicate enhanced capabilities, perhaps better protection against harsh environments. It could have a higher degree of protection against dust, moisture, or electromagnetic interference, making it ideal for use in even more extreme industrial settings compared to the standard FC – TSAI – 1620M.

Honeywell FC – TSAI – 1620R

The “R” might suggest a redundant design. In applications where high availability is non – negotiable, such as in aerospace or nuclear power, the redundant features of this model can ensure continuous operation. If one component fails, the redundant part can take over, minimizing the risk of system downtime.

Honeywell FC – TSAI – 1620S

The “S” could imply a focus on speed. For applications that require rapid signal processing and response times, like high – speed manufacturing lines, the FC – TSAI – 1620S might offer faster analog – to – digital conversion rates, enabling more timely control actions.

Honeywell FC – TSAI – 1620E

Possibly an enhanced version, the “E” model may have additional features such as advanced diagnostic capabilities or improved communication interfaces. It could provide more detailed information about the module’s health and the quality of the incoming signals, facilitating more proactive maintenance.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Honeywell FC – TSAI – 1620M, ensure the installation area has a temperature between – 40°C and 70°C and humidity within 5% to 95% RH (non – condensing). Use appropriate tools like screwdrivers for the screw terminals. Disconnect all power sources in the system to avoid electrical hazards. Verify the compatibility of the module with the existing control system, especially in terms of power supply requirements. Mount the module on a suitable TS32 / TS35 x 7.5 DIN EN rail, ensuring it is securely fastened. Prepare the wires according to the specified diameter (max. 2.5mm² or AWG 14) and strip the ends to 7mm for proper connection.

Maintenance Suggestions

Regularly inspect the FC – TSAI – 1620M for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the module’s operating temperature to ensure it remains within the normal range. Use diagnostic tools to check the functionality of each input channel. In case of a malfunction, first check the power supply and wiring connections. If the problem persists, refer to the product manual for detailed troubleshooting steps. When replacing parts, always use genuine Honeywell components to maintain the module’s performance and reliability. Keep records of maintenance activities and any issues encountered for future reference.

7. Service and Guarantee Commitment

Honeywell stands firmly behind the FC – TSAI – 1620M with a comprehensive service and guarantee. The product typically comes with a 12 – month warranty, during which any manufacturing defects will be rectified at no cost to the customer. Honeywell’s global network of technical support teams is available around the clock. Whether it’s assistance with installation, commissioning, or troubleshooting, their experts can provide prompt and accurate solutions. They also offer regular product updates and enhancements to keep the FC – TSAI – 1620M at the forefront of analog input module technology. This commitment reflects Honeywell’s confidence in the product’s quality and its dedication to meeting the long – term needs of its customers in the industrial automation field.