Description

Detailed parameter table

**

|

Parameter name

|

Parameter value

|

|

Product model

|

FTA – T – 02

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Digital output module

|

|

Number of channels

|

24 (organized into 6 groups of 4)

|

|

Power supply

|

Compatible with 24/48/60 VDC

|

|

Operating temperature

|

– 25 °C to 70 °C

|

|

Humidity range

|

5 % to 95 % RH (non – condensing)

|

|

Maximum voltage

|

36 VAC / 50 VDC (IEC 1010, overvoltage category 3); 125 VAC / 150 VDC (IEC 1010, overvoltage category 2)

|

|

Maximum continuous current per channel

|

2 A

|

|

Termination type

|

Screw terminals

|

|

Max. wire diameter

|

0.25 cm² (AWG 14)

|

|

Strip length

|

0.7 cm (0.28 in)

|

|

Tightening torque

|

0.5 Nm (0.37 ft – lb)

|

|

Dimensions (L×W×H)

|

14.5 cm x 7 cm x 5.7 cm

|

|

Weight

|

0.44 lbs

|

|

Din rail compatibility

|

TS32 / TS35 x 7.5

|

|

Used rail length

|

14.6 cm (5.75 in)

|

|

Certifications

|

CE, ROHS, UL

|

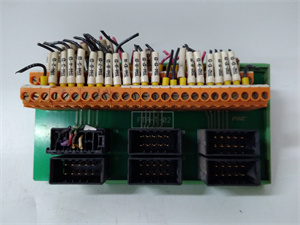

Honeywell FTA-T-02

Product introduction

The Honeywell FTA – T – 02 is a fail – safe digital output module, an essential component in industrial automation systems. Developed by the globally recognized brand Honeywell, this module is designed to ensure reliable and secure control in various industrial setups.

It serves as a crucial interface between system interconnection cables (SIC) and external field wiring. With 24 digital output channels grouped into 6 sets of 4, the FTA – T – 02 can effectively control multiple devices in industrial processes. In an industrial control system, it receives digital signals from the control unit and then accurately outputs corresponding control commands to actuators such as motors, valves, and relays. This enables precise regulation of industrial operations, whether it’s controlling the opening and closing of valves in a chemical plant or the start – stop of motors in a manufacturing facility.

Core advantages and technical highlights

High reliability and fail – safe design:

The Honeywell FTA – T – 02 is engineered with reliability in mind. It is a fail – safe module, meaning that in the event of a system malfunction or power failure, it will default to a safe state. This is crucial for applications where safety is of utmost importance, such as in oil and gas refineries or power generation plants. The module has been tested and certified with CE, ROHS, and UL approvals, ensuring it meets strict international safety and quality standards. Its ability to operate within a wide temperature range from – 25 °C to 70 °C and humidity range of 5 % to 95 % RH makes it suitable for harsh industrial environments.

Precise control capabilities:

Equipped with 24 output channels, the FTA – T – 02 offers precise control over industrial equipment. Each channel can handle a maximum continuous current of 2 A, allowing it to drive a variety of actuators. The screw terminal termination type provides a secure and reliable connection for wiring. The specified tightening torque of 0.5 Nm ensures that the connections are stable, minimizing the risk of loose connections that could lead to signal loss or equipment malfunction. This level of precision in control is vital for applications that require accurate and consistent operation, like in high – precision manufacturing processes.

Easy integration and installation:

The Honeywell FTA – T – 02 is designed for easy integration into existing industrial control systems. It is compatible with a wide range of power supplies, including 24/48/60 VDC, reducing the need for complex power conversion. The module can be easily mounted on a TS32 / TS35 x 7.5 din rail, with a used rail length of 14.6 cm. This standard din rail compatibility simplifies the installation process, as it can be quickly snapped into place. The clear specifications for wire diameter (up to 0.25 cm² or AWG 14) and strip length (0.7 cm) further facilitate wiring, making it accessible for technicians to install and maintain.

Honeywell FTA-T-02

Typical application scenarios

In the oil and gas industry, the Honeywell FTA – T – 02 is used to control the opening and closing of valves in pipelines. For example, in a large – scale oil refinery, it can receive signals from the central control system based on parameters such as pressure, flow rate, and temperature. The FTA – T – 02 then outputs control signals to the valves, ensuring the safe and efficient transfer of oil and gas. In case of an emergency, its fail – safe design will close the valves to prevent leaks and potential disasters.

In power generation plants, the module plays a key role in controlling the operation of generators and associated equipment. It can control the start – stop of cooling fans, the opening and closing of circuit breakers, and the adjustment of voltage regulators. By accurately controlling these components, the FTA – T – 02 helps maintain the stable operation of the power grid and ensures the reliable supply of electricity.

For manufacturing plants, especially those with automated production lines, the FTA – T – 02 is used to control robotic arms, conveyor belts, and other machinery. It can receive commands from the production control system and output signals to precisely position robotic arms for picking and placing components, or to start and stop conveyor belts at the right time. This improves production efficiency and product quality, as the precise control reduces errors and waste.

Related model recommendations

Honeywell FTA – T – 14:

This is also a digital output module from Honeywell. While the FTA – T – 02 has 24 output channels, the FTA – T – 14 may have a different number of channels (e.g., 4 as in some related models). The FTA – T – 14 could be a more suitable choice for smaller – scale applications where fewer output channels are required, reducing costs and complexity.

Honeywell FTA – T – 21:

Part of the same product line, the FTA – T – 21 might offer additional features or a higher capacity. It could have more advanced signal processing capabilities or support for a wider range of industrial protocols. For larger industrial complexes with more complex control requirements, the FTA – T – 21 could provide the enhanced functionality needed.

Honeywell FTA – S – 02:

The “S” in the model name might indicate a version optimized for speed. If an application requires rapid response times for output control, such as in high – speed manufacturing lines where milliseconds matter, the FTA – S – 02 could be a better option compared to the standard FTA – T – 02.

Honeywell FTA – T – 02R:

The “R” likely suggests a redundant version. In applications where high availability is critical, such as in aerospace or nuclear power industries, the FTA – T – 02R provides an extra layer of reliability. In case of a failure in the primary module, the redundant part can take over immediately, ensuring continuous operation of the control system.

Honeywell FTA – T – 02H:

The “H” could imply a version that is more suitable for hazardous environments. With additional explosion – proof or flame – retardant features, the FTA – T – 02H is a viable choice for use in industries like coal mines or chemical plants where the risk of explosion is high.

Installation, commissioning and maintenance instructions

Installation preparation:

Before installing the Honeywell FTA – T – 02, ensure that the installation area is clean and dry. The ambient temperature should be within the specified – 25 °C to 70 °C range. Use appropriate tools such as screwdrivers to handle the screw terminals. Disconnect all power sources from the system to prevent electrical shocks during installation. Verify the compatibility of the FTA – T – 02 with the existing control system in terms of power supply voltage and communication protocols (if applicable). Mount the module on a suitable TS32 / TS35 x 7.5 din rail, ensuring it is securely fastened. Prepare the wires according to the specified diameter (up to 0.25 cm² or AWG 14) and strip the ends to a length of 0.7 cm for proper connection.

Maintenance suggestions:

Regularly inspect the Honeywell FTA – T – 02 for any signs of physical damage, such as cracks in the casing or loose connections. Check the temperature of the module during operation to ensure it is within the normal range, as overheating could indicate a problem. Use diagnostic tools to check the functionality of each output channel. In case of a malfunction, first check the power supply and wiring connections. If the problem persists, refer to the product manual for detailed troubleshooting steps. When replacing parts, always use genuine Honeywell components to maintain the module’s performance and reliability. Keep records of maintenance activities and any issues encountered for future reference.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the Honeywell FTA – T – 02. The product comes with a standard 12 – month warranty, during which any manufacturing defects will be rectified free of charge. Honeywell’s global network of technical support teams is available around the clock. Whether you need assistance with installation, commissioning, or troubleshooting, their experts can provide timely and accurate solutions. They also offer regular product updates and enhancements to ensure the FTA – T – 02 remains at the forefront of industrial digital output module technology. This commitment reflects Honeywell’s confidence in the quality of the FTA – T – 02 and its dedication to meeting the long – term needs of its customers in the industrial automation sector.