Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | FTA – T – 21 |

| Manufacturer | Honeywell |

| Product category | Digital input module |

| Input voltage range | 125 VAC / 150 VDC |

| Number of channels | 16 digital input channels |

| Operating temperature | – 40 °C to + 70 °C |

| Isolation rating | 1000 VAC (rms) @ 1 min |

| Dimensions (L×W×H) | 9.2 cm x 7.1 cm x 5.8 cm |

| Weight | 0.12 kg |

| Approvals | CE, TUV, UL 508, CSA |

| Communication protocol | Not clearly specified in available sources, but likely compatible with common industrial protocols for seamless integration |

| Connection type | Standard PLC interface for easy integration into control systems |

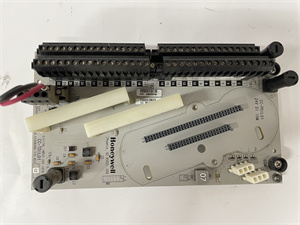

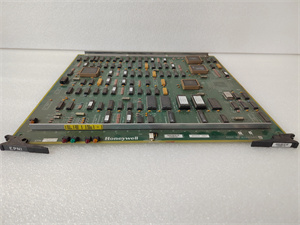

Honeywell FTA-T-21

Product introduction

The Honeywell FTA – T – 21 is a high – performance digital input module crafted by the industry – renowned brand, Honeywell. This module is an integral part of industrial control systems, playing a crucial role in facilitating the seamless transfer of digital signals. It is designed to accurately detect and convert external digital input signals into a format that can be easily processed by the central control unit of an automation system.

In the context of industrial automation, the Honeywell FTA – T – 21 serves as a reliable link between various field devices and the control system. For example, it can receive signals from sensors, switches, and other digital – outputting devices in industrial settings. By integrating the FTA – T – 21 into a control system, operators can gain real – time insights into the status of the industrial process. This helps in making informed decisions, optimizing process efficiency, and ensuring the overall safety and reliability of the industrial operation. Whether in manufacturing plants, power generation facilities, or chemical processing units, the Honeywell FTA – T – 21 is a key component for maintaining smooth and efficient industrial automation.

Core advantages and technical highlights

Robust and reliable design:

The Honeywell FTA – T – 21 is built to endure harsh industrial environments. With an operating temperature range spanning from – 40 °C to + 70 °C, it can function optimally in extreme cold or hot conditions. The 1000 VAC (rms) isolation rating at 1 minute protects the module from electrical interference, ensuring stable signal input. This robust construction reduces the risk of system failures and minimizes downtime, providing continuous operation for industrial processes.

Precise signal handling:

Equipped with 16 digital input channels, the FTA – T – 21 can accurately handle a diverse range of digital signals. It can precisely detect the state of input signals, whether it is a simple on – off signal from a switch or a more complex digital code from a sensor. The module is designed to deliver consistent and accurate results, enabling precise control over industrial machinery and processes.

Easy integration:

Featuring a standard PLC interface, the Honeywell FTA – T – 21 can be easily integrated into existing industrial control systems. This compatibility allows for seamless connectivity with other components such as PLCs, HMIs, and other control devices. It ensures that the module can be quickly installed and commissioned, reducing the time and effort required for system integration and expansion.

Honeywell FTA-T-21

Typical application scenarios

In manufacturing plants, the Honeywell FTA – T – 21 is extensively used to monitor the status of production lines. For instance, it can connect to proximity sensors that detect the presence of components on an assembly line. By receiving these digital signals, the control system can determine if the assembly process is proceeding as planned. If a component is missing or misaligned, the system can trigger an alarm or adjust the operation of robotic arms to correct the issue, thus improving production efficiency and product quality.

In power generation facilities, the module plays a vital role in monitoring and controlling electrical systems. It can be connected to switches and sensors that indicate the status of circuit breakers, transformers, and other electrical equipment. For example, if a circuit breaker trips, the FTA – T – 21 can quickly detect the change in the digital input signal and relay this information to the control system. The control system can then take appropriate actions, such as isolating the faulty section and notifying maintenance personnel, ensuring the stable operation of the power grid.

For industrial safety systems, the Honeywell FTA – T – 21 is used to monitor emergency stop buttons, safety interlocks, and other safety – related devices. When an emergency stop button is pressed or a safety interlock is breached, the module immediately sends a signal to the control system, which can then initiate emergency shutdown procedures. This helps to protect personnel and equipment from potential hazards, making the industrial environment safer.

In power generation facilities, the module plays a vital role in monitoring and controlling electrical systems. It can be connected to switches and sensors that indicate the status of circuit breakers, transformers, and other electrical equipment. For example, if a circuit breaker trips, the FTA – T – 21 can quickly detect the change in the digital input signal and relay this information to the control system. The control system can then take appropriate actions, such as isolating the faulty section and notifying maintenance personnel, ensuring the stable operation of the power grid.

For industrial safety systems, the Honeywell FTA – T – 21 is used to monitor emergency stop buttons, safety interlocks, and other safety – related devices. When an emergency stop button is pressed or a safety interlock is breached, the module immediately sends a signal to the control system, which can then initiate emergency shutdown procedures. This helps to protect personnel and equipment from potential hazards, making the industrial environment safer.

Related model recommendations

Honeywell FTA – T – 22:

This could potentially be an upgraded version of the FTA – T – 21. It might offer additional features such as more input channels, enhanced signal processing capabilities, or better compatibility with newer industrial control systems. It is suitable for applications where the requirements are more demanding than what the FTA – T – 21 can offer, such as in large – scale industrial complexes with a high density of digital input devices.

Honeywell FTA – S – 21:

The “S” in the model name could indicate a version optimized for speed. It may have faster response times for signal detection and processing, making it ideal for applications where real – time monitoring and quick decision – making are crucial, like high – speed manufacturing lines or time – sensitive industrial processes.

Honeywell FTA – T – 16:

This model may have a different form factor or a reduced number of input channels compared to the FTA – T – 21. It could be designed for less complex industrial applications or for use in space – constrained environments where the full functionality of the FTA – T – 21 is not required, but basic digital input monitoring is still needed.

Honeywell FTA – T – 21R:

The “R” might suggest a redundant version. In applications where high availability is critical, such as in aerospace or nuclear power industries, the FTA – T – 21R can provide an extra layer of reliability. In case of a failure in the primary module, the redundant part can take over immediately, ensuring continuous operation of the control system.

Honeywell FTA – T – 21H:

The “H” could imply a version that is more suitable for hazardous environments. It may have additional safety features, such as increased explosion – proof or flame – retardant capabilities, making it a viable choice for use in oil and gas refineries, chemical plants, or other industries where the risk of explosion is high.

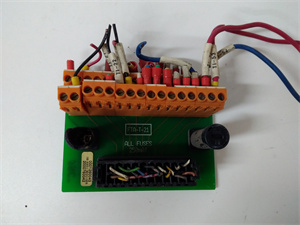

Installation, commissioning and maintenance instructions

Installation preparation:

Before installing the Honeywell FTA – T – 21, ensure that the installation area is clean, dry, and free from electromagnetic interference. The ambient temperature should be within the specified – 40 °C to + 70 °C range. Use appropriate tools such as screwdrivers and wire strippers for installation. Disconnect all power sources from the system to prevent electrical shocks. Verify the compatibility of the FTA – T – 21 with existing equipment in terms of input voltage range, communication protocols (if applicable), and physical dimensions. Mount the module in a secure location within the industrial control cabinet, following the provided installation guidelines. Make sure to properly connect all input cables, ensuring a tight and secure connection to avoid signal loss or interference.

Maintenance suggestions:

Regularly inspect the Honeywell FTA – T – 21 for any signs of physical damage, such as cracks in the casing or loose connections. Use diagnostic tools to check the module’s performance, including the accuracy of input signal detection. Clean the module periodically to remove dust, as dust accumulation can affect its heat dissipation and electrical performance. In case of a malfunction, first check the power supply and input cables. If the problem persists, refer to the product manual for detailed troubleshooting steps. When replacing parts, always use genuine Honeywell components to maintain the module’s performance and reliability. Keep records of maintenance activities and any issues encountered for future reference.

Service and guarantee commitment

Honeywell stands firmly behind the Honeywell FTA – T – 21 with a comprehensive service and guarantee. The product comes with a standard warranty period, during which any manufacturing defects will be rectified free of charge. Honeywell’s global network of technical support teams is available around the clock. Whether it’s assistance with installation, commissioning, or troubleshooting, their experts can provide timely and accurate solutions. They also offer regular product updates and enhancements to ensure the FTA – T – 21 remains at the forefront of industrial digital input module technology. This commitment reflects Honeywell’s confidence in the quality of the FTA – T – 21 and its dedication to meeting the long – term needs of its customers in the industrial automation sector.