Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

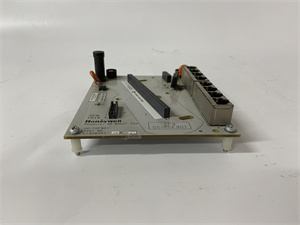

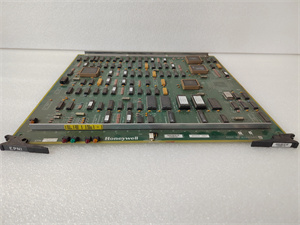

| Product model | LCNP4E |

| Manufacturer | Honeywell |

| Product category | Industrial control module |

| Operating voltage | 220 V |

| Output frequency | 50 kHz |

| Operating temperature | -20°C ~ +60°C |

| Storage temperature | -40°C ~ +85°C |

| Dimensions (L×W×H) | 100 x 50 x 30 mm |

| Weight | 0.5 kg |

| Certification | CE, UL, CSA |

| Series | LCNP4E series |

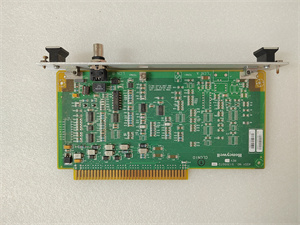

| Communication protocol | Modbus RTU, BACnet |

| Installation method | Modular, easy to install |

LCNP4E

Product introduction

The Honeywell LCNP4E is a high – performance industrial control module that plays a pivotal role in advanced automation systems. Engineered by the renowned brand Honeywell, the LCNP4E is designed to offer precise control capabilities, making it an essential component for various industrial applications.

This module belongs to the LCNP4E series, which is known for its reliability and efficiency. It serves as a bridge for different devices within an automation system, enabling seamless communication and data exchange. In industrial settings, it can connect sensors, actuators, and controllers, allowing for the accurate monitoring and regulation of processes. Whether in manufacturing plants, oil and gas facilities, or chemical processing units, the Honeywell LCNP4E ensures smooth operation and contributes to enhanced productivity.

Core advantages and technical highlights

Reliable and stable:

The Honeywell LCNP4E is built with industrial – grade components, ensuring its ability to function flawlessly even in harsh environments. With an operating temperature range from -20°C to +60°C, it can withstand extreme heat and cold. Its stable performance under varying conditions reduces the risk of system failures, providing continuous operation for industrial processes.

Versatile communication:

Featuring support for multiple communication protocols such as Modbus RTU and BACnet, the LCNP4E can integrate with a wide range of devices. This versatility enables it to be used in diverse industrial setups, regardless of the equipment’s brand or origin. It allows for seamless data sharing and control commands transmission, enhancing the overall system’s functionality.

Easy installation and maintenance:

Thanks to its modular design, the LCNP4E is easy to install. Technicians can quickly set it up in existing systems without complex wiring or configuration. During maintenance, individual modules can be easily replaced if there is a malfunction, minimizing downtime and reducing maintenance costs. This design also simplifies troubleshooting, as issues can be isolated to specific modules.

LCNP4E

Typical application scenarios

In the building automation industry, the Honeywell LCNP4E is used to manage and control various building systems. It can connect temperature sensors, humidity sensors, and lighting controls, enabling centralized management. For example, in large commercial buildings, the LCNP4E can adjust the HVAC system based on real – time environmental data, optimizing energy consumption and providing a comfortable indoor environment.

In industrial manufacturing, this module is crucial for controlling production lines. It can communicate with PLCs, robots, and conveyor belts, ensuring coordinated operation. For instance, in an automotive assembly plant, the LCNP4E can precisely control the movement of robotic arms, guaranteeing accurate part assembly and improving production efficiency.

In the energy sector, such as power plants and oil refineries, the LCNP4E is used for monitoring and controlling critical processes. It can connect sensors that measure parameters like pressure, flow, and temperature, and then transmit this data to the central control system. This allows operators to make informed decisions and maintain the safe and efficient operation of energy – related facilities.

Related model recommendations

LCNP4E – R:

This is a redundant version of the LCNP4E. It is designed for applications where high – availability is crucial, such as in data centers or hospitals. The redundant feature ensures that if one module fails, the other can immediately take over, preventing system downtime.

LCNP4E – H:

The LCNP4E – H is optimized for high – temperature environments. It is suitable for use in industries like steel manufacturing or glass production, where the operating temperature can be extremely high. Its special design allows it to maintain performance under such harsh thermal conditions.

LCNP4E – S:

This model focuses on high – speed communication. It is ideal for applications that require rapid data transfer, such as high – speed production lines or real – time monitoring systems. The LCNP4E – S can handle large amounts of data quickly, reducing latency in the automation system.

LCNP4E – C:

The LCNP4E – C is enhanced in terms of compatibility. It can work with a broader range of legacy systems and non – standard devices. This makes it a great choice for retrofitting projects, where integrating new technology with existing infrastructure is a challenge.

LCNP4E – M:

The LCNP4E – M is a more compact version of the LCNP4E. It is designed for applications where space is limited, such as in small – scale industrial setups or compact control cabinets. Despite its smaller size, it still retains the core functionality of the original LCNP4E.

Installation, commissioning and maintenance instructions

Installation preparation:

Before installing the Honeywell LCNP4E, ensure the installation area is clean, dry, and free from electromagnetic interference. The ambient temperature should be within the specified -20°C to +60°C range. Use appropriate tools, such as screwdrivers and wire strippers, for installation. Disconnect all power sources from the system to prevent electrical shocks. Verify the compatibility of the LCNP4E with existing equipment in terms of voltage, communication protocols, and interface types. Mount the module in a secure location, following the provided installation guidelines.

Maintenance suggestions:

Regularly inspect the LCNP4E for any signs of physical damage, such as cracks or loose connections. Use diagnostic tools to check the module’s performance, including its output frequency and communication status. Clean the module periodically to remove dust, as dust accumulation can affect its heat dissipation and electrical performance. In case of a malfunction, first check the power supply and communication cables. If the problem persists, refer to the product manual for detailed troubleshooting steps. When replacing parts, always use genuine Honeywell components to maintain the module’s performance and reliability.

Service and guarantee commitment

Honeywell stands firmly behind the Honeywell LCNP4E with a comprehensive service and guarantee. The product comes with a standard warranty, during which any manufacturing defects will be rectified free of charge. Honeywell’s global network of technical support teams is available around the clock. Whether you need assistance with installation, commissioning, or troubleshooting, their experts can provide timely and accurate solutions. They also offer regular software updates and product enhancements to ensure the LCNP4E remains at the forefront of industrial control technology. This commitment reflects Honeywell’s confidence in the quality of the LCNP4E and its dedication to meeting the long – term needs of its customers in the industrial automation sector.