Description

1. Product Overview

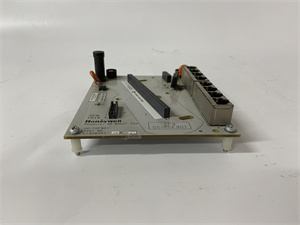

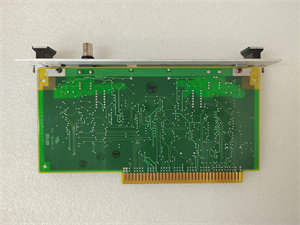

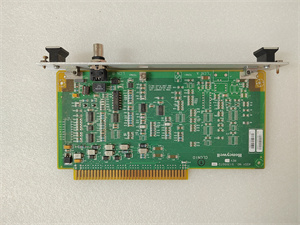

The Honeywell TC – CCN014 is a high – performance redundant net interface module, designed to meet the complex requirements of modern industrial automation systems. As a crucial part of Honeywell’s extensive industrial control product portfolio, this module plays a vital role in enhancing the reliability and connectivity of industrial networks.

2. Technical Parameters

- Supply Voltage: Operates within a range of 5 – 24 V, providing flexibility in power source selection to match different industrial setups.

- Power Consumption: Approximately 18 W, ensuring efficient power usage while maintaining high – performance operation.

- Output Frequency: 50 kHz, enabling fast and stable data transmission for real – time control and monitoring in industrial processes.

- Protocol Support: Supports a wide array of communication protocols, including Modbus TCP/IP, Ethernet/IP, PROFINET, CC – Link IE, CANopen, DeviceNet, and ControlNet. This extensive protocol support allows seamless integration with diverse industrial devices and systems.

- Dimensions: Compact dimensions of 1.5″ x 6.6″ x 5.2″ (3.8 cm x 16.8 cm x 13.2 cm) make it easy to install in various industrial equipment, even in spaces with limited room.

- Weight: Lightweight, weighing only 0.45 kg, reducing the load on equipment and facilitating easy handling during installation and maintenance.

- Operating Temperature Range: Can operate in a wide temperature range, suitable for harsh industrial environments. It can withstand temperatures from – 20 °C to 70 °C, ensuring reliable performance in extreme conditions.

- Input Signal Types: Supports multiple input signal types to meet different application scenarios, enabling it to interface with a variety of sensors and devices.

3. Core Advantages

- Redundant Design for High Reliability: The TC – CCN014 features a redundant design, which is of utmost importance in industrial applications where continuous operation is critical. In the event of a failure in the primary network interface, the module can automatically switch to the redundant interface. This ensures that communication within the industrial control system remains uninterrupted. For example, in a power generation plant, any disruption in communication could lead to a halt in power generation. The redundant design of the TC – CCN014 minimizes such risks, providing a reliable communication solution that helps maintain the smooth operation of the plant.

- Versatile Protocol Support: With support for multiple communication protocols, the TC – CCN014 offers unparalleled versatility. It can communicate with a diverse range of devices that use different protocols. In a manufacturing plant with a mix of devices from various manufacturers, each using different communication standards, the TC – CCN014 can bridge the communication gap. It can translate data between different protocols, allowing all devices to work together in harmony. This versatility reduces the need for complex and costly protocol – conversion equipment, making it a cost – effective solution for industrial communication.

- Compact and Easy – to – Integrate Design: Despite its powerful capabilities, the TC – CCN014 has a compact design. This makes it easy to install in various industrial equipment, even in spaces with limited room. Its small form factor does not compromise on performance. Additionally, it is designed for easy integration into existing industrial control systems. The module can be quickly set up and configured, reducing installation time and minimizing system downtime during upgrades or expansions.

HONEYWELL TC-CCN014

4. Typical Application Scenarios

- Oil and Gas Industry: In oil refineries, the TC – CCN014 can ensure reliable communication between the control systems that monitor and regulate the refining process. The redundant design is crucial here, as any communication failure could lead to safety hazards and production losses. It enables seamless data transfer between sensors that measure temperature, pressure, and flow of crude oil and refined products, and the control units that adjust the operation of pumps, valves, and other equipment.

- Manufacturing Sector: Especially in automotive and electronics manufacturing, the TC – CCN014 plays a vital role. In an automotive assembly line, it can facilitate communication between robotic arms, conveyor belts, and other automated equipment. The module ensures that the control system can accurately receive data from sensors on the production line and send control signals to the actuators. This helps in maintaining the efficiency and precision of the assembly process, reducing errors and improving overall productivity.

- Power Generation Industry: Whether it’s a coal – fired power plant, a hydroelectric power station, or a wind farm, the TC – CCN014 is essential. It enables reliable communication between the power generation equipment, monitoring systems, and control centers. In a wind farm, for example, it can transmit data from wind turbines about their performance, such as rotation speed, power output, and blade angles, to the central control room. The redundant design ensures that this communication is not interrupted, even in harsh weather conditions, allowing for efficient operation and maintenance of the wind farm.

5. Related Model Recommendations

- Honeywell TC – OAH061: It is also a redundant interface control module, similar in function to the TC – CCN014. The TC – OAH061 can be used in tandem with the TC – CCN014 in larger and more complex industrial control systems. Together, they can further enhance the redundancy and reliability of the network communication, providing an extra layer of protection against communication failures.

- Honeywell CC – PAON01: This is an analog input/output module. In an industrial control system, the TC – CCN014 can work with the CC – PAON01. The TC – CCN014 is responsible for network communication, while the CC – PAON01 can handle the input and output of analog signals. For example, it can receive analog signals from sensors and send them through the network via the TC – CCN014 for further processing.

- Honeywell CC – PCNT01: A C300 controller module. The TC – CCN014 can be integrated with the CC – PCNT01. The CC – PCNT01 controls the overall logic of the industrial process, and the TC – CCN014 provides it with reliable network communication capabilities, enabling seamless data transfer between the controller and other devices in the system.

- Honeywell CC – PDOB01: A digital output IOTA module. The TC – CCN014 can communicate with the CC – PDOB01. The CC – PDOB01 is responsible for sending digital output signals to control actuators, and the TC – CCN014 ensures that the control commands are accurately transmitted over the network, coordinating the operation of the industrial equipment.

- Honeywell CC – PWRR01: A redundant power supply module. Although different in function from the TC – CCN014, in an industrial control system, they can work together to enhance the overall reliability of the system. The CC – PWRR01 provides redundant power, and the TC – CCN014 provides redundant network communication, ensuring that both power and communication are reliable, which is crucial for continuous operation in industrial applications.

HONEYWELL TC-CCN014

6. Installation, Commissioning and Maintenance Instructions

- Installation Preparation: Before installing the TC – CCN014, ensure that the installation area is clean, dry, and free from excessive dust and moisture. The ambient temperature should be within the recommended operating range. Disconnect all power sources from the system to prevent electrical accidents. Use appropriate anti – static equipment to protect the module from electrostatic discharge. Check the compatibility of the TC – CCN014 with other components in the system, including verifying the correct voltage levels and communication protocols. Also, ensure that the physical mounting location has enough space to accommodate the module, considering its compact but not negligible size.

- Commissioning: Once installed, power on the system gradually. Use the dedicated configuration software provided by Honeywell to set up the module’s communication parameters. Configure the redundant interface settings to ensure seamless failover in case of a primary interface failure. Test the module’s communication capabilities by sending test data packets to other devices on the network. Check if the module is correctly identifying and communicating with all connected devices. Verify the redundant function by simulating a failure of the primary network interface to ensure that the module switches to the redundant interface without any data loss or disruption in communication.

- Maintenance Suggestions: Regularly inspect the TC – CCN014 for any signs of physical damage, such as cracks in the casing or loose connections. Clean the module periodically to remove dust, as dust accumulation can affect its performance, especially in relation to heat dissipation. Monitor the module’s performance using the built – in diagnostic tools or the control system software. If there are any communication issues, check the network cables, configuration settings, and the status of other connected devices. Update the module’s firmware when new versions are released by Honeywell to ensure optimal performance, security, and compatibility with the latest industrial standards and system configurations.

7. Service and Guarantee Commitment

Honeywell stands firmly behind the TC – CCN014 with a comprehensive service and guarantee. The product comes with a standard warranty period, during which any manufacturing defects will be rectified free of charge. Honeywell’s global network of technical support teams is available around the clock. Whether it’s providing installation guidance, helping with complex troubleshooting, or offering advice on system integration, their experts are well – equipped to assist. The company also invests continuously in research and development, which may lead to future firmware updates and improvements for the TC – CCN014. This commitment reflects Honeywell’s confidence in the product’s quality and its dedication to meeting the long – term needs of its customers in the industrial automation field.