Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | TK – FPDXX2 |

| Manufacturer | Honeywell |

| Product category | Industrial control module (function can vary, with potential in power supply, sensor interface, etc.) |

| Input voltage range | 90 – 264 VAC (selectable as 170 – 265 VAC in some specifications) |

| Output current | Up to 2.5 A (varies by output voltage levels: e.g., 1.5A @ 1.2V, 4A @ 3.3V, 10A @ 5.1V, 2.8A @ 24.0V) |

| Dimensions (L x D x H) | 11.2 x 14.5 x 14.0 cm (4.41 x 5.71 x 5.51 in) |

| Weight | Approximately 1.1 kg (2.5 lb) |

| Interface type | SPI, I²C and potentially others for communication and connection to other components |

| Communication protocol | TCP/IP, UDP, HTTP and multi – protocol support for versatile data transfer |

| Operating temperature range | – 40 °C to 85 °C |

| Storage temperature range | Not specified in all sources, but common industrial modules have a wide range, e.g., – 55 °C to 125 °C |

| Memory | Expandable up to 128 MB |

| Installation method | Mounted on a chassis, for example, on the left side of the chassis (does not consume a slot in some setups) |

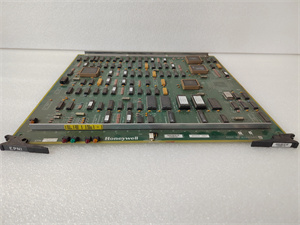

Honeywell TK-FPDXX2

Product introduction

The Honeywell TK – FPDXX2 is a remarkable industrial control module, engineered to bring precision and reliability to a diverse range of industrial applications. As part of Honeywell’s extensive and respected product lineup, the TK – FPDXX2 is designed with state – of – the – art technology to meet the complex demands of modern industrial automation.

This module can function in multiple capacities, such as a power supply module providing stable power for industrial systems. With a wide input voltage range of 90 – 264 VAC, it can adapt to various power grids around the world. It also has significant output current capabilities, making it suitable for powering different devices within an industrial setup. Additionally, it might serve as an interface for sensors and actuators, enabling seamless communication and control within the automation system. Its role is pivotal in enhancing the overall efficiency and performance of industrial processes, whether in manufacturing plants, power generation facilities, or other industrial sectors.

Core advantages and technical highlights

High – reliability power supply

When acting as a power supply module, the Honeywell TK – FPDXX2 offers outstanding reliability. It has a wide input voltage range, ensuring stable operation even in regions with inconsistent power grids. The non – replaceable soldered – in – place fuse provides reliable protection against over – current situations. For example, in industrial areas where power fluctuations are common, the TK – FPDXX2 can continue to supply clean and stable power to sensitive equipment, preventing malfunctions and data loss.

Versatile communication capabilities

Equipped with support for multiple communication protocols like TCP/IP, UDP, and HTTP, the TK – FPDXX2 can easily integrate into existing industrial networks. This versatility allows it to communicate with a wide range of devices, from PLCs and HMIs to various sensors and actuators. In a large – scale manufacturing plant, the module can transfer data in real – time between different components of the automation system, enabling efficient monitoring and control of the entire production process.

Robust construction for harsh environments

Built with a robust design, the TK – FPDXX2 can withstand harsh industrial environments. Its operating temperature range of – 40 °C to 85 °C means it can function reliably in extreme cold or hot conditions. Whether it’s deployed in a cold storage facility or a high – temperature industrial furnace area, the module’s performance remains stable. This durability reduces the need for frequent replacements and maintenance, saving both time and costs for industrial operations.

Honeywell TK-FPDXX2

Typical application scenarios

In manufacturing plants, the Honeywell TK – FPDXX2 can be used to power and control automated production lines. For instance, it can supply power to robotic arms and conveyor belts while also receiving sensor data to adjust their operations. If a sensor detects a misaligned part on the conveyor belt, the TK – FPDXX2 can quickly process the information and send control signals to the robotic arm to correct the position, ensuring smooth production flow.

In power generation facilities, the module can play a crucial role in monitoring and controlling power – related parameters. It can interface with sensors that measure voltage, current, and temperature in generators and transformers. If there is an abnormal increase in temperature, the TK – FPDXX2 can trigger an alarm and initiate corrective actions, such as adjusting cooling systems, to prevent equipment failures and ensure continuous power supply.

In the oil and gas industry, the TK – FPDXX2 can be used in remote monitoring stations. It can power the sensors that detect pressure, flow rate, and gas composition in pipelines. The module can then transmit this data over long – distance communication networks to a central control room, allowing operators to monitor and manage the oil and gas transportation process effectively, even in harsh and remote environments.

Related model recommendations

Honeywell TK – FPDXX3

Likely an upgraded version of the TK – FPDXX2, it may offer enhanced processing power, higher output current, or additional communication interfaces. It could be suitable for applications with more demanding power and data – handling requirements, such as large – scale industrial complexes with numerous connected devices.

Honeywell C300 – related I/O modules

Modules within the Honeywell C300 series, like analog input/output and digital input/output modules, can work in tandem with the TK – FPDXX2. For example, analog input modules can collect data from sensors, and the TK – FPDXX2 can process and distribute this data within the control system, forming a comprehensive and efficient control solution.

Honeywell T775 (temperature controller)

Although different in function, in an industrial environment where temperature control is crucial, the Honeywell T775 can be integrated with the TK – FPDXX2. The TK – FPDXX2 can power the T775 and help in transmitting the temperature – related data to other parts of the control system for overall process optimization.

Honeywell T850 (outdoor – optimized temperature controller)

Similar to the T775, but designed for outdoor use. In applications where the TK – FPDXX2 is used in outdoor industrial setups, such as weather monitoring stations or outdoor equipment control, the T850 can be paired with it. The TK – FPDXX2 provides power and communication support for the T850 to accurately control and monitor temperatures in harsh outdoor conditions.

Honeywell C200 controllers

These controllers can be used in combination with the TK – FPDXX2 in industrial control systems. The C200 controllers handle the overall control logic, while the TK – FPDXX2 can provide power and interface with field devices, enabling seamless operation of the entire control system.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell TK – FPDXX2, ensure the installation area is clean, dry, and free from excessive dust and moisture. The ambient temperature should be within the specified operating range of – 40 °C to 85 °C. Use appropriate electrical tools and follow all safety regulations. Disconnect the power supply to the system where the module will be installed to prevent electrical shock. Check the compatibility of the TK – FPDXX2 with other components in the system, such as ensuring that the chassis mounting location has the correct mechanical and electrical interfaces.

Commissioning

After installation, power on the system. Use the relevant configuration software provided by Honeywell to set up the module’s communication parameters, such as IP addresses for network – based communication. If it’s a power – supply – related module, verify the output voltage and current levels to ensure they match the requirements of the connected devices. Test the module’s functionality by sending test signals (if applicable) and checking for proper responses from connected components.

Maintenance suggestions

Regularly inspect the Honeywell TK – FPDXX2 for any signs of physical damage, such as cracks or loose connections. Clean the module periodically to remove dust, as dust accumulation can affect its performance, especially in high – temperature environments. Check the power supply output regularly to ensure it remains stable. If there are any issues, refer to the user manual for troubleshooting steps. In case of component failures, use only genuine Honeywell replacement parts to maintain the module’s performance and reliability. Keep the module’s firmware up – to – date by downloading the latest versions from Honeywell’s official website to benefit from performance improvements and bug fixes.

Service and guarantee commitment

Honeywell stands firmly behind the Honeywell TK – FPDXX2 with a comprehensive service and guarantee. The product comes with a standard warranty, during which any manufacturing defects will be rectified at no cost to the customer. Honeywell’s global network of technical support teams is available 24/7. Whether it’s providing installation guidance, helping with complex troubleshooting, or offering advice on system integration, their experts are well – equipped to assist. The company also invests continuously in research and development, which may lead to future firmware updates and improvements for the TK – FPDXX2. This commitment reflects Honeywell’s confidence in the product’s quality and its dedication to meeting the long – term needs of its customers in the industrial automation field.