Description

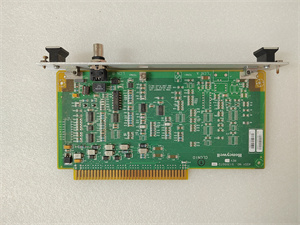

Honeywell TK – IOLI01 Product Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | TK – IOLI01 |

| Manufacturer | Honeywell |

| Product category | I/O Link Interface Module |

| Communication interfaces supported | Analog signals, digital signals, Ethernet |

| Number of input/output channels | Multiple (capable of handling numerous signals simultaneously) |

| Signal types supported | Current, voltage, switch signals, frequencies |

| Configuration options | Flexible, customizable according to application needs |

| Built – in functions | Signal conversion, amplification, filtering |

| Power requirements | 24 VDC |

| Power consumption | 10 W |

| Operating temperature range | – 40 °C to 70 °C (- 40 °F to 158 °F) |

| Storage temperature range | – 40 °C to 85 °C (- 40 °F to 185 °F) |

| Humidity tolerance | 0 to 95 % rh, non – condensing |

| Vibration resistance | 0.5 g rms, 5 to 500 Hz |

| Shock resistance | 15 g, 11 ms |

| Dimensions | 134 x 71 x 21 mm (5.3 x 2.8 x 0.8 in) |

| Weight | 0.45 kg (1.0 lb) |

Honeywell TK-IOLI01

Product introduction

The Honeywell TK – IOLI01 is a high – performance I/O Link Interface Module, playing a crucial role in industrial automation and control systems. As an integral part of Honeywell’s advanced control product portfolio, it is engineered to meet the complex demands of modern industrial operations.

This module serves as a vital bridge, enabling seamless communication between different devices and systems within an industrial setup. With its support for a wide range of communication interfaces, including analog, digital, and Ethernet, the TK – IOLI01 can connect to various types of equipment, such as sensors, actuators, and encoders. It features multiple input and output channels, allowing it to simultaneously connect to and process a large number of signals. In the Honeywell Experion LS system, specifically within the C200 series, the TK – IOLI01 acts as an essential interface, coordinating data transfer and control commands between the system and field – level devices. Its ability to handle diverse signal types, from analog currents and voltages to digital switch signals and frequencies, makes it suitable for a wide array of industrial applications.

Core advantages and technical highlights

Versatile signal handling

The Honeywell TK – IOLI01 stands out for its ability to handle an extensive range of signal types. Whether it’s the continuous analog signals like current and voltage, which are crucial for measuring physical parameters in industrial processes, or the discrete digital signals such as switch states that control the on – off operations of devices, this module can manage them all. Additionally, it can process frequency – based signals, which are common in applications involving rotating machinery or pulse – based sensors. This versatility ensures that it can be integrated into almost any industrial control scenario, regardless of the type of sensors and actuators in use.

Flexible configuration

Flexibility in configuration is another key strength of the TK – IOLI01. Users can customize the module according to their specific application requirements. This includes setting parameters related to signal processing, communication protocols, and input/output channel assignments. For example, in a manufacturing plant where different production lines may have unique control needs, the TK – IOLI01 can be configured to adapt to each line’s specific sensor – actuator setups. This adaptability not only simplifies the integration process but also allows for more efficient and tailored control within industrial systems.

Built – in data processing

Equipped with built – in data processing capabilities, the TK – IOLI01 can perform functions such as signal conversion, amplification, and filtering. Signal conversion ensures that incoming signals are in the appropriate format for further processing within the control system. Amplification boosts weak signals to a level where they can be accurately detected and processed, while filtering removes noise and interference, enhancing the quality and reliability of the signals. In a noisy industrial environment, for instance, the filtering function can significantly improve the accuracy of sensor data, leading to more precise control decisions. These built – in data processing functions contribute to the overall high – performance operation of the module in industrial automation applications.

Honeywell TK-IOLI01

Typical application scenarios

Manufacturing industry

In manufacturing plants, the Honeywell TK – IOLI01 is extensively used to manage production lines. It can connect to a multitude of sensors, such as proximity sensors that detect the presence of components on conveyor belts, and temperature sensors that monitor the operating conditions of machinery. By processing the data from these sensors, the module can send control signals to actuators, like robotic arms for precise component assembly or motors for adjusting conveyor belt speeds. In a car manufacturing plant, for example, the TK – IOLI01 can coordinate the movement of various robotic stations, ensuring that parts are assembled accurately and production flow is smooth.

Energy sector

In power generation plants, whether they are coal – fired, gas – fired, or renewable energy facilities, the TK – IOLI01 plays a critical role. It can interface with sensors that measure parameters like the pressure and temperature of steam in a thermal power plant or the wind speed and blade pitch in a wind farm. Based on the data received, the module can control actuators such as valves to regulate steam flow or motors to adjust the pitch of wind turbine blades. This helps in optimizing energy production, ensuring the safe and efficient operation of power – generation equipment, and maintaining grid stability.

Chemical industry

Chemical plants deal with complex processes that require precise control. The TK – IOLI01 is used to connect to sensors that monitor variables like chemical concentrations, pH levels, and flow rates. It can then control valves and pumps to adjust the chemical reactions and material flow. In a petrochemical refinery, for example, the module can manage the distillation process by controlling the temperature and pressure in distillation columns, ensuring the production of high – quality products while minimizing waste and maintaining safety standards.

Related model recommendations

TK – IOLI02 (hypothetical upgrade)

This could potentially be an upgraded version of the TK – IOLI01. It might offer enhanced processing speed for handling a larger volume of signals more rapidly. It could also have additional communication protocols support, allowing for even more versatile integration with a wider range of modern and legacy industrial devices. For applications that are expanding and require higher – performance I/O interface capabilities, the TK – IOLI02 could be a suitable choice.

Honeywell C200 – related I/O modules

Modules like analog input/output and digital input/output modules in the Honeywell C200 system are designed to work in tandem with the TK – IOLI01. For example, an analog input module can collect data from sensors that measure continuous variables such as temperature or pressure, and then pass this data to the TK – IOLI01 for further processing and integration into the overall control system. These I/O modules expand the capabilities of the system by providing a means to interface with different types of field devices.

Honeywell C300 – compatible I/O Link modules

Although from a different series within Honeywell’s control systems, some C300 – compatible I/O Link modules can be used in larger – scale industrial control setups where the TK – IOLI01 is also present. They may have similar functions in terms of I/O link communication but could be optimized for different levels of complexity or specific application requirements within the plant – wide control network.

Honeywell Experion PKS – related interface modules

Modules within the Honeywell Experion PKS (Process Knowledge System) can be used in scenarios where the TK – IOLI01 is part of a distributed control network. They can communicate with the TK – IOLI01 to manage overall plant – wide operations, with the TK – IOLI01 handling local – level I/O link – related tasks at specific process units, while the Experion PKS – related modules manage higher – level coordination and data aggregation.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell TK – IOLI01, ensure that the power to the entire control system is switched off to prevent electrical hazards. The installation environment should be clean, dry, and free from excessive dust and humidity. Use anti – static tools and wear an anti – static wristband to protect the module from electrostatic discharge, as its sensitive components can be easily damaged by static electricity. Check the compatibility of the TK – IOLI01 with the existing control system, including verifying that the backplane or mounting location has the correct mechanical and electrical interfaces. Also, make sure that the power supply available meets the module’s requirements of 24 VDC.

Commissioning

Once the TK – IOLI01 is installed, power on the control system. Use the appropriate configuration software provided by Honeywell to set up the module’s communication parameters, such as IP addresses for Ethernet communication, and configure the input/output channels according to the application needs. Test the module’s functionality by sending test signals to connected devices and verifying that the module can correctly receive and process the data. If any error messages are displayed during commissioning, carefully review the installation steps, wiring connections, and configuration settings to identify and resolve the issues.

Maintenance suggestions

Regularly inspect the TK – IOLI01 for any signs of physical damage, such as cracks on the circuit board or loose connectors. Clean the module gently using compressed air to remove any dust that may have accumulated over time, especially in the ventilation areas. Periodically update the module’s firmware, if available, to improve performance, fix any bugs, and enhance compatibility with other devices. Monitor the module’s power consumption and operating temperature to detect any abnormal behavior. In case of component failure, replace faulty parts with genuine Honeywell components to ensure the continued reliable operation of the module. Keep a detailed record of all maintenance activities, including inspection dates, firmware updates, and any repairs carried out, for future reference.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the Honeywell TK – IOLI01. Each module undergoes strict quality control procedures during manufacturing to meet the highest industry standards. Honeywell provides a standard warranty period, during which any manufacturing defects will be rectified promptly. In case of problems, their global network of technical support experts is available to offer detailed installation guidance, efficient troubleshooting, and maintenance advice. Honeywell also invests in continuous research and development, which may lead to software updates and improvements for the TK – IOLI01 over time. This commitment showcases Honeywell’s confidence in the product’s quality and its dedication to ensuring customer satisfaction in the industrial control domain.