Description

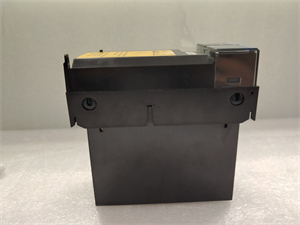

Honeywell TK – PRS021 Product Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | TK – PRS021 |

| Manufacturer | Honeywell |

| Product category | Control Processor Module |

| Processor type | Advanced microcontroller |

| Memory capacity | 64 kb |

| Operating voltage | 24 V DC |

| Communication interfaces | Modbus, Ethernet, RS – 485 |

| Power consumption | ≤ 15 W |

| Operating temperature | – 40 °C to + 85 °C |

| Storage temperature | – 40 °C to + 85 °C |

| Dimensions | 130 mm x 100 mm x 35 mm |

| Weight | 0.25 kg |

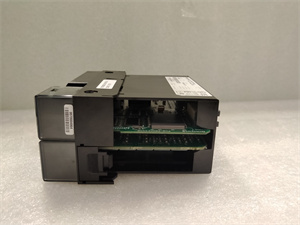

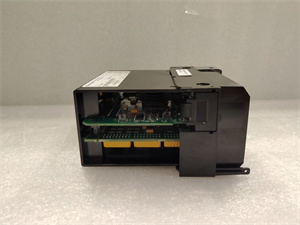

Honeywell TK-PRS021

Product introduction

The Honeywell TK – PRS021 is a high – performance control processor module, playing a pivotal role in industrial automation and control systems. As an integral part of Honeywell’s advanced control solutions, it is designed to meet the complex demands of modern industrial operations.

This module features an advanced microcontroller that enables efficient processing of control algorithms and data. With a 64 – kb memory capacity, it can store necessary programs and data for seamless operation. The TK – PRS021 serves as the “brain” of the control system, receiving input signals from various sensors and devices, processing them in real – time, and then sending out control commands to actuators. It is often used in the Honeywell C200 control system, where it coordinates with other components such as I/O link interfaces, redundancy modules, FTE interfaces, and fieldbus modules. This integration allows for comprehensive control and monitoring of industrial processes, ensuring optimal performance and productivity.

Core advantages and technical highlights

High – performance processing

The advanced microcontroller in the Honeywell TK – PRS021 offers fast and reliable processing power. It can handle complex control tasks, such as executing multiple control loops simultaneously. In industrial applications where real – time response is crucial, like in chemical plants where process parameters need to be adjusted instantly, the TK – PRS021 can quickly process incoming data and send out appropriate control signals. This high – speed processing minimizes delays and improves the overall efficiency of the control system.

Versatile communication capabilities

Equipped with Modbus, Ethernet, and RS – 485 communication interfaces, the TK – PRS021 enables seamless data exchange with a wide range of industrial devices. Modbus allows for easy connection to legacy equipment, while Ethernet provides high – speed data transfer for modern, network – connected systems. The RS – 485 interface is useful for communicating with devices over longer distances in harsh industrial environments. This versatility in communication ensures that the TK – PRS021 can be integrated into existing industrial automation setups without much hassle, regardless of the type of devices already in use.

Robust design for harsh environments

Designed to operate within a wide temperature range from – 40 °C to + 85 °C, the TK – PRS021 can withstand harsh industrial conditions. Whether it’s in a cold storage facility or a high – temperature industrial furnace area, the module remains functional. Its compact size of 130 mm x 100 mm x 35 mm and lightweight of 0.25 kg make it easy to install in tight spaces. Additionally, its design is likely to include protection against electromagnetic interference, ensuring stable operation even in electrically noisy environments.

Honeywell TK-PRS021

Typical application scenarios

Oil and gas industry

In oil refineries and gas processing plants, the Honeywell TK – PRS021 is used to control and monitor critical processes. It can manage the flow of crude oil through pipelines, adjust the temperature and pressure in distillation towers, and control the operation of pumps and compressors. For example, it can receive data from pressure sensors in pipelines and, based on pre – set parameters, send commands to control valves to maintain the optimal pressure. The module’s ability to communicate with various devices over different protocols is beneficial as oil and gas plants often have a mix of old and new equipment.

Power generation

In power plants, be it coal – fired, gas – fired, or renewable energy power plants, the TK – PRS021 plays a vital role. It can control the operation of turbines, generators, and other power – generation equipment. In a wind farm, for instance, it can receive data from wind speed sensors, pitch angle sensors on wind turbine blades, and generator status sensors. Using this data, it can adjust the pitch of the blades to optimize energy capture and control the speed of the generator. The module’s high – performance processing ensures that power generation can be adjusted in real – time according to the changing conditions of the power grid and the availability of energy sources.

Manufacturing

In manufacturing industries, the TK – PRS021 is used for process control on production lines. In an automotive manufacturing plant, it can control the movement of robotic arms, the speed of conveyor belts, and the quality control systems. It can receive data from vision sensors used for quality inspection and, if a defect is detected, send commands to stop the production line or trigger a rework process. The module’s compatibility with different communication protocols allows it to integrate with other manufacturing – related devices such as Programmable Logic Controllers (PLCs) and Human – Machine Interfaces (HMIs), enabling smooth operation of the entire manufacturing process.

Related model recommendations

TK – PRS022

This is likely an upgraded version of the TK – PRS021. It may offer enhanced processing power, more memory, or additional communication options. For applications that require higher performance or more complex control strategies as the production process expands or becomes more sophisticated, the TK – PRS022 can be a suitable upgrade choice.

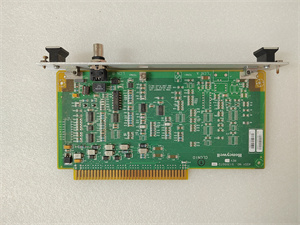

Honeywell C200 – related I/O modules

Modules like those for analog input/output or digital input/output in the Honeywell C200 system are designed to work in tandem with the TK – PRS021. For example, an analog input module can collect data from sensors that measure continuous variables such as temperature or pressure, and then send this data to the TK – PRS021 for processing. These I/O modules expand the capabilities of the overall control system by providing a means to interface with different types of field devices.

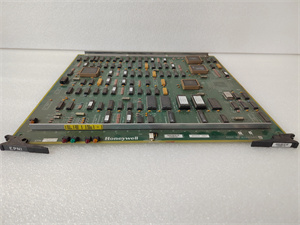

Honeywell TDC 3000 – compatible modules

Although from an older system, some TDC 3000 – compatible modules can be used in legacy systems where the TK – PRS021 is being introduced for an upgrade. They may have similar functions in terms of control and communication, and with proper integration, can work together to modernize the control system while still leveraging existing infrastructure.

Honeywell PKS – related controllers

Controllers in the Honeywell Process Knowledge System (PKS) can be used in larger – scale industrial control scenarios where the TK – PRS021 is part of a distributed control network. They can communicate with the TK – PRS021 to manage overall plant – wide operations, with the TK – PRS021 handling local – level control tasks at specific process units.

Honeywell S9000 – related modules

These modules are from another Honeywell control system series. They can be considered for applications where there is a need to integrate different Honeywell technologies. The S9000 – related modules may offer unique features such as advanced diagnostic capabilities or specialized control algorithms that can complement the functions of the TK – PRS021 in a complex industrial control setup.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell TK – PRS021, ensure that the power to the control system is turned off to prevent electrical accidents. The installation environment should be clean, dry, and free from excessive dust and humidity. Use appropriate anti – static tools and precautions, such as anti – static wristbands, to protect the module from electrostatic discharge, which could damage its sensitive components. Check the compatibility of the TK – PRS021 with the existing control system, including ensuring that the backplane or mounting location has the correct dimensions and electrical connections. Also, verify that the power supply available meets the module’s requirements of 24 V DC.

Commissioning

Once installed, power on the control system and check for any error messages on the associated control panels or diagnostic software. Use the provided configuration tools to set up the communication parameters for the TK – PRS021, such as IP addresses for Ethernet communication and Modbus settings. Test the module’s functionality by sending and receiving data from connected devices. For example, if it’s connected to a sensor, check if the module can correctly receive and process the sensor data. If any issues are encountered during commissioning, carefully review the installation steps, wiring connections, and configuration settings to identify and resolve the problem.

Maintenance suggestions

Regularly inspect the TK – PRS021 for any signs of physical damage, such as cracks on the circuit board or loose connectors. Clean the module gently using compressed air to remove dust that may accumulate over time, especially in the ventilation areas. Periodically update the module’s firmware, if available, to improve performance, fix bugs, and enhance compatibility with other devices. Monitor the module’s power consumption and operating temperature to detect any abnormal behavior. In case of component failure, replace faulty parts with genuine Honeywell components to ensure the continued reliable operation of the module. Keep a record of all maintenance activities, including inspection dates, firmware updates, and any repairs carried out, for future reference.

Service and guarantee commitment

Honeywell stands firmly behind the Honeywell TK – PRS021 with a comprehensive service and guarantee commitment. Each TK – PRS021 module undergoes rigorous quality control procedures during manufacturing to ensure it meets the highest industry standards. Honeywell offers a standard warranty period, during which any manufacturing defects will be addressed promptly. In case of issues, their global network of technical support experts is available to provide assistance. They can offer detailed installation guidance, efficient troubleshooting, and advice on maintenance. Honeywell also invests in continuous research and development, which may result in software updates and improvements for the TK – PRS021 over time. This commitment reflects Honeywell’s confidence in the product’s quality and its dedication to ensuring customer satisfaction in the industrial control domain.