Description

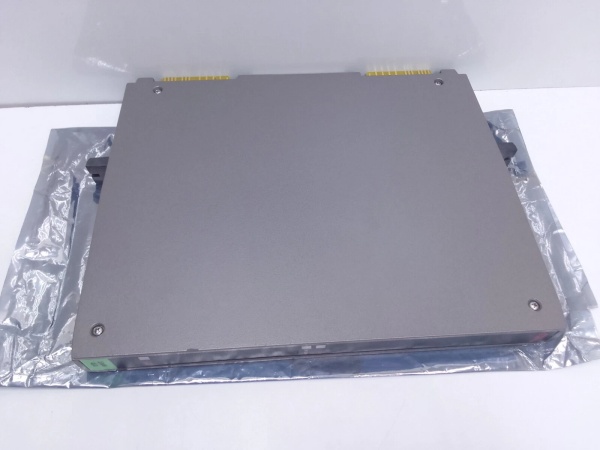

ICS Triplex T3431-IM

-

Model Number: T3431-IM -

Product Type: Thermocouple Input Module (24-Channel) -

Input Channels: 24 differential thermocouple inputs (grouped into 3 sets of 8) -

Thermocouple Types: J, K, S, T (configurable per group) -

Accuracy: 0.1% of full scale -

Temperature Range: -40°C to 85°C (operating); -40°C to 125°C (storage) -

Resolution: 0.1°C (configurable as tenths or units) -

Cold Junction Compensation (CJC): Built-in, ±1°C accuracy -

Noise Rejection: 70 dB minimum at 60/120 Hz -

Response Time: 50 ms maximum (step input) -

Power Supply: 24V DC (±10% tolerance) -

Isolation: 2500 VAC galvanic isolation between input module and multiplexer -

Redundancy: Triple Modular Redundant (TMR) with voter circuit -

Fault Diagnostics: Thermocouple burnout detection, open circuit detection, channel status monitoring -

Communication: Integrates with Trusted TMR controllers via proprietary backplane (e.g., T8100) -

Dimensions: 368mm (W) x 267mm (H) x 140mm (D) (approximate) -

Weight: ~5kg (approximate) -

Certifications: SIL 3 (IEC 61508), TÜV, UL, CE

ICS Triplex T3431-IM

-

Oil & Gas: Monitors furnace temperatures in refineries, pipeline heaters, and offshore platforms. Its TMR design ensures reliable operation in harsh offshore environments, while SIL 3 certification meets industry safety standards. -

Chemical Processing: Controls temperature in reactors, distillation columns, and polymerization processes. The module’s high precision (0.1%) ensures consistent product quality, while fault diagnostics prevent costly shutdowns. -

Power Generation: Monitors boiler temperatures in coal-fired or gas-fired power plants. Its wide operating temperature range and vibration resistance make it suitable for plant environments, while TMR redundancy ensures uninterrupted power generation. -

Manufacturing: Controls temperature in plastic molding machines, extrusion lines, and drying ovens. The module’s fast response time (50 ms) enables real-time adjustments to maintain product consistency.