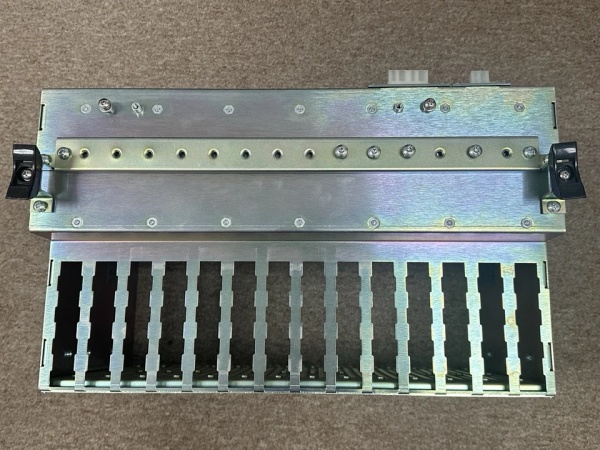

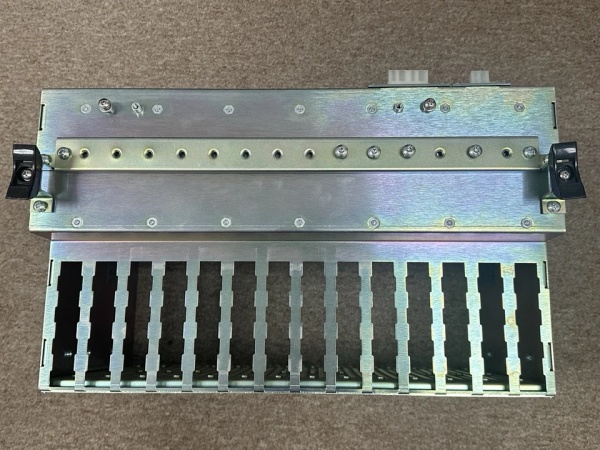

ICS Triplex T8300 | Trusted TMR System Chassis

Product Type: Trusted TMR System Chassis

Series: Trusted TMR System

Core Function: Provides physical housing and backplane connectivity for Trusted TMR system modules

Key Specs: 19-inch rack mount, 12-slot configuration, 24V DC operation

This product is already in your quote request list.