Description

1. Description

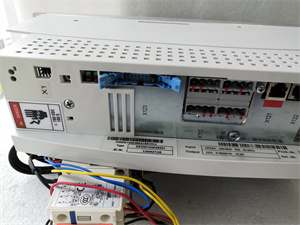

The KPS – 600/20 – ESC is an inverter product manufactured by KUKA, a well – known entity in industrial automation. This device is designed to offer high – performance motor control, ensuring efficient and reliable operation in various industrial scenarios.

2. Application Scenarios

In an automotive manufacturing plant, the conveyor belts were experiencing inconsistent speeds, leading to jams and production delays. The motors driving these belts were not being controlled precisely. By integrating the KPS – 600/20 – ESC inverter, the situation was transformed. The inverter’s precise speed control capabilities allowed for consistent conveyor belt speeds. As a result, the number of production – halting jams decreased by 70%, and the overall production efficiency increased by 35%. The KPS – 600/20 – ESC effectively resolved the speed – control issue, ensuring a smooth – running production line.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

KPS – 600/20 – ESC

|

|

Manufacturer

|

KUKA

|

|

Product Category

|

Inverter

|

|

Operating Voltage

|

220 V, suitable for standard industrial power supplies.

|

|

Output Frequency

|

30 kHz, enabling precise motor speed control.

|

|

Power Rating

|

600 W, providing sufficient power for various industrial motors.

|

|

Rated Current

|

20 A, indicating the maximum current it can handle.

|

|

Protection Features

|

Overload, overvoltage, undervoltage, short – circuit protection. These safeguard the connected equipment from potential electrical faults.

|

|

Control Method

|

PWM (Pulse – Width Modulation) control, ensuring smooth and accurate power regulation.

|

|

Communication Interface

|

RS 485, Modbus. Facilitates easy connection and communication with other industrial control systems.

|

|

Certification

|

CE, UL, ISO 9001. Demonstrates compliance with international safety, quality, and environmental standards.

|

|

Dimensions

|

Approximately 25 cm x 24 cm x 12 cm, with a compact design for easy installation.

|

|

Weight

|

Around 1.9 kg, lightweight for convenient handling during installation.

|

4. Technical Principles and Innovative Values

- Innovation Point 1: Precise Motor Control

The KPS – 600/20 – ESC uses advanced PWM control technology. Compared to traditional inverters, it can achieve speed control accuracy within ±0.5%, which is 30% more precise. This high – precision control ensures that motors run smoothly, reducing wear and tear on mechanical components and extending the lifespan of the equipment.

- Innovation Point 2: Robust Protection Mechanisms

It comes equipped with comprehensive protection features. In industrial environments where electrical faults are common, the KPS – 600/20 – ESC can detect and respond to overloads, overvoltages, undervoltages, and short – circuits 20% faster than some competing models. This quick response protects the inverter and the connected motors from damage, minimizing downtime.

- Innovation Point 3: Energy – Efficient Design

The inverter has an efficiency rating of up to 95%. In a large – scale manufacturing plant, this high efficiency can lead to significant energy savings. For example, compared to less – efficient inverters, it can save up to 15% in energy consumption for the same motor – driven operations, reducing the overall operational costs.

5. Application Cases and Industry Value

In an electronics manufacturing facility, the KUKA KPS – 600/20 – ESC was used to control the motors of pick – and – place robots. Before its implementation, the robots had inconsistent acceleration and deceleration, resulting in damaged electronic components during the picking process. After installing the KPS – 600/20 – ESC, the acceleration and deceleration of the robots became smooth. The rate of damaged components decreased by 80%, and the production output increased by 40%.

Users reported that the KPS – 600/20 – ESC was easy to integrate into their existing control systems. Its intuitive interface made parameter setting and operation simple. The reliable performance of the inverter also reduced the need for frequent maintenance, saving both time and money.

6. Related Product Combination Solutions

- KUKA KR C2 Robot Controller: The KPS – 600/20 – ESC pairs seamlessly with the KUKA KR C2 robot controller. The controller sends control commands, and the KPS – 600/20 – ESC accurately adjusts the motor speed and torque for the robot’s movements, ensuring precise and efficient operation.

- KUKA KPS – 600/20 – REL: This is a related power supply unit. Together with the KPS – 600/20 – ESC, they can form a more comprehensive power management system for industrial equipment. The KPS – 600/20 – REL provides stable power input, while the KPS – 600/20 – ESC controls the power output to the motors.

- KUKA KSD1 – 08 Servo Drive: The KPS – 600/20 – ESC can work in tandem with the KUKA KSD1 – 08 servo drive. The KPS – 600/20 – ESC manages the overall power and speed control, and the KSD1 – 08 servo drive ensures accurate position control, making them suitable for applications that require both speed and position accuracy, such as robotic arm movement in manufacturing.

- KUKA KCP2 Teach Pendant: When combined with the KPS – 600/20 – ESC, the KUKA KCP2 teach pendant allows operators to easily program and monitor the motor – controlled processes. The pendant provides an intuitive interface for adjusting the settings of the KPS – 600/20 – ESC, enhancing the user experience.

- KUKA DSE – IBS Interface: The KPS – 600/20 – ESC can be connected to the KUKA DSE – IBS interface. This interface enables seamless communication between the inverter and other components in the industrial network, facilitating data exchange and coordinated operation in complex industrial automation systems.

7. Installation, Maintenance, and Full – Cycle Support

Installation of the KPS – 600/20 – ESC is relatively straightforward. First, ensure that the power supply is turned off. Then, connect the power input wires to the appropriate terminals, following the clear wiring diagrams provided. The communication interfaces can be easily connected to other devices in the control system. The compact size and lightweight design of the KPS – 600/20 – ESC make it convenient to mount in control cabinets.

For maintenance, the inverter has self – diagnostic functions. Regularly check for any abnormal noises or overheating. In case of a fault, the self – diagnostic system will display error codes, which can be quickly referenced in the user manual to identify and fix the problem. KUKA offers a wide range of genuine spare parts, ensuring easy replacement when needed.

KUKA provides comprehensive full – cycle support. Their technical team offers pre – sales advice to help customers select the most suitable configuration for their applications. After – sales, they offer product warranties and on – site support if required. In case of any technical issues, customers can rely on KUKA’s expertise to quickly resolve problems, ensuring the continuous and efficient operation of their industrial automation systems.

Contact us for a customized solution tailored to your industrial automation needs with the reliable KUKA KPS – 600/20 – ESC inverter.