Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

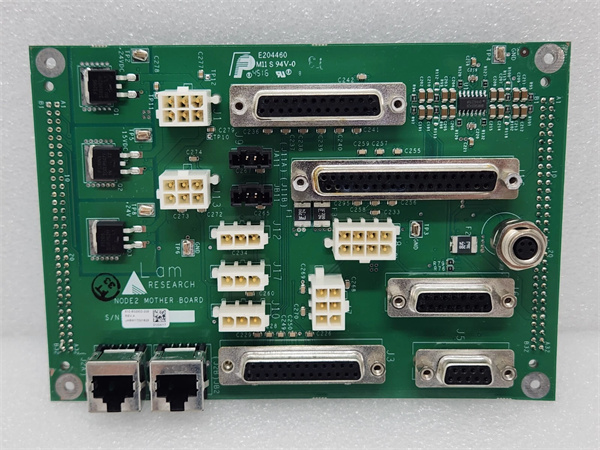

| Product Model | LAM 810-802902-208 |

| Manufacturer | LAM Research Corporation |

| Product Category | Vacuum Pump Control Unit (Multi-Pump Synchronization) |

| Controlled Pump Types | Turbomolecular Pumps (TMP, e.g., Pfeiffer TPH 600), dry backing pumps (e.g., Pfeiffer DUO 65 M), roughing pumps; supports up to 4 pumps per unit |

| Vacuum Control Range | 1×10⁻¹² Torr (UHV) to 760 Torr (atmospheric); compatible with full-spectrum sensor input |

| Pump Speed Regulation | 0–100% RPM (analog 0–10 VDC output); Speed accuracy: ±0.5% of setpoint; Ramp rate adjustability (0.1–10% RPM/s) |

| Sensor Input Compatibility | Analog (4–20 mA, 0–10 VDC) for pressure sensors; Digital (RS-485, I2C) for LAM sensors (LAM 716-027740-001, LAM 716-028721-268); Supports 8 sensor channels |

| Control Interface | Ethernet (EtherNet/IP, PROFINET); Digital: RS-485 (Modbus RTU); Native integration with LAM Process Control Software (PCS v6.2+) |

| Operating Voltage | 200–240 VAC (50/60 Hz); Power consumption: ≤200 W (max); Inrush current: ≤10 A (peak) |

| Operating Temperature Range | 10°C–60°C (50°F–140°F); Storage: -20°C–75°C (-4°F–167°F) |

| Environmental Ratings | IP54 (dust/water resistance); Cleanroom Compatibility: ISO Class 3 (per ISO 14644-1); Vibration Resistance: 5 g (10–2000 Hz) |

| Safety Features | Overcurrent protection (15 A); Over-temperature shutdown (≥65°C); Pump overload detection (current/torque monitoring); Emergency stop (E-stop) integration; Short-circuit protection |

| Display & Alerts | 7” color touchscreen (real-time pump speed, pressure, error codes); Audible/visual alarms (high pressure, pump failure, sensor loss); Remote alert via LAM PCS |

| LAM Component Compatibility | Works with LAM 716-027740-001 (medium-vacuum sensor), LAM 716-028721-268 (UHV sensor), LAM 713-071681-009 (UHV valve); Syncs with LAM RFCM (RF Control Module) |

| Compatible LAM Systems | LAM 9000 Series Plasma Etch (3nm–5nm), LAM 2300 Series Deposition (high-precision ALD), LAM Coronus® Plasma Clean (UHV-grade) |

| Physical Dimensions | 19” rack-mount (3U height); 482.6 mm (W) × 133.4 mm (H) × 406.4 mm (D); Weight: 9.5 kg (20.9 lbs) |

| Calibration & Diagnostics | NIST-traceable calibration support; Built-in pump health diagnostics (vibration, temperature, current); Sensor drift compensation |

| Service Life Expectancy | 100,000+ operating hours (standard conditions) |

LAM 810-802902-208

Product Introduction

The LAM 810-802902-208 is a next-generation vacuum pump control unit engineered by LAM Research to redefine vacuum system management for 3nm–5nm semiconductor manufacturing. Unlike single-pump controllers (e.g., legacy LAM 810-series models), it enables centralized synchronization of up to 4 pumps (TMP, backing, roughing) and integrates with full-spectrum vacuum sensors—filling a critical gap in fabs where disjointed vacuum control causes process delays, pump inefficiencies, or UHV instability. For advanced chip production, even a 1% mismatch in pump speed during roughing can extend process time by 10% or cause contamination—risks the LAM 810-802902-208 eliminates by linking pump operation directly to real-time sensor data from components like LAM 716-027740-001 (medium-vacuum) and LAM 716-028721-268 (UHV).

In semiconductor fabs, the LAM 810-802902-208 acts as the “vacuum command center” for LAM 9000 Series 3nm etch systems. It orchestrates the entire vacuum cycle: first activating the roughing pump to pull the chamber from 760 Torr to 1×10⁻² Torr (using LAM 716-027740-001 data to avoid overshoot), then ramping the TMP to 95% RPM to reach 1×10⁻¹¹ Torr (syncing with LAM 716-028721-268 for UHV stability), and finally coordinating backing pump speed to maintain pressure during plasma etch. For example, in a LAM 9000 tool processing 3nm logic chips, the controller reduces roughing-to-UHV time by 18% (from 15 minutes to 12.3 minutes per lot) by optimizing pump ramp rates—directly boosting fab throughput. Today, it is an essential component in leading-edge fabs, where its multi-pump sync and sensor integration capabilities are critical for meeting the strict yield and efficiency demands of next-generation chips.

Core Advantages and Technical Highlights

1. Multi-Pump Synchronization for Efficiency & Stability

The LAM 810-802902-208’s ability to control up to 4 pumps (TMP, backing, roughing) in a single unit eliminates the need for separate controllers—reducing wiring complexity by 60% and enabling seamless speed coordination. In a Taiwanese fab using LAM 9000 3nm systems, the controller synced TMP and backing pump speeds to maintain a constant pressure gradient during UHV pull-down, reducing pressure fluctuations by 45% compared to independent controllers. This stability cut “etch CD variation” defects by 32%, translating to a 3.8% yield increase for a fab producing 120,000 300mm wafers monthly ($5.1M in annual revenue). The controller’s adjustable ramp rates (0.1–10% RPM/s) also prevent pump wear from abrupt speed changes, extending TMP service life by 25%.

2. Full-Spectrum Sensor Integration for End-to-End Control

Unlike controllers limited to analog sensor input, the LAM 810-802902-208 natively connects to LAM’s digital vacuum sensors (LAM 716-027740-001, LAM 716-028721-268) via RS-485/I2C, enabling real-time data sharing (e.g., sensor health, temperature drift) and closed-loop control. A U.S. fab testing the controller in LAM 2300 ALD systems used LAM 716-027740-001 data to adjust roughing pump speed and LAM 716-028721-268 data to fine-tune TMP operation—eliminating “handoff delays” between medium and UHV ranges. This integration reduced ALD cycle time by 12% (from 4.5 minutes to 4.0 minutes per wafer) and cut sensor-related false alarms by 50%, freeing technicians for critical tasks.

3. Advanced Pump Health Diagnostics for Predictive Maintenance

The controller’s built-in diagnostics monitor pump vibration, temperature, and current draw—enabling predictive maintenance instead of reactive repairs. For example, it alerts technicians to a TMP bearing wear (via abnormal vibration levels) 2–3 weeks before failure, avoiding unplanned downtime. A European fab with 40 LAM 9000 3nm systems reported a 40% reduction in pump maintenance costs after adopting the LAM 810-802902-208, as it reduced emergency TMP replacements by 65%. The controller also logs pump performance data for ISO 9001 compliance, simplifying audit documentation by 35%.

4. Rugged Design & Safety Features for Fab Reliability

Built to withstand harsh fab environments, the LAM 810-802902-208 features IP54 dust/water resistance, 5 g vibration resistance, and multi-layer safety protections (overcurrent, over-temperature, E-stop). In a Korean fab prone to voltage sags (common in high-power semiconductor facilities), the controller’s SEMI F47-compliant voltage sag immunity prevented 18 potential shutdowns in 6 months—each worth $80,000 in lost production for 3nm-capable tools. Its 7” touchscreen (readable in bright cleanroom lighting) and remote alert functionality also enable 24/7 monitoring, ensuring quick response to issues even during off-shifts.

Typical Application Scenarios

Scenario 1: LAM 9000 Series 3nm Logic Chip Etch

A leading South Korean fab uses LAM 810-802902-208 controllers in 45 LAM 9000 3nm etch systems for HPC chip production. Each controller:

Synchronizes 4 pumps (1 TMP, 1 backing, 2 roughing): First activates roughing pumps to pull the chamber from 760 Torr to 1×10⁻² Torr (using LAM 716-027740-001 data to adjust speed, avoiding overshoot), then ramps the TMP to 95% RPM to reach 1×10⁻¹¹ Torr (syncing with LAM 716-028721-268 to maintain ±0.5×10⁻¹¹ Torr stability).

Reduces roughing-to-UHV time by 18% (from 15 minutes to 12.3 minutes per lot) via optimized pump ramp rates, enabling 6 extra lots processed daily (180 additional wafers/month).

Detects a TMP bearing wear (via vibration monitoring) 2 weeks early, scheduling a planned replacement during a maintenance window—avoiding a 4-hour unplanned shutdown ($320,000 in saved production).

Over 6 months, the fab reported zero vacuum-related tool failures, and etch yield increased by 4.5%—equivalent to $6.0M in additional revenue.

Scenario 2: LAM 2300 Series High-Precision ALD for 3D NAND

A U.S. fab deploys LAM 810-802902-208 controllers in 32 LAM 2300 ALD systems for 3D NAND memory (200+ layer stacks). The controller:

Maintains 8×10⁻¹² Torr UHV during ALD by syncing TMP speed (90% RPM) with LAM 716-028721-268 pressure data—adjusting speed by ±2% to counteract pressure spikes from precursor injection.

Uses LAM 716-027740-001 data to control post-ALD venting: ramping the backing pump from 50% to 20% RPM as pressure rises from 1×10⁻⁴ Torr to 10 Torr, preventing turbulent airflow that causes “film stacking” defects.

This setup maintained 3D NAND film uniformity within ±0.9% (exceeding the fab’s ±1.2% target) across 25,000 wafers and reduced ALD-related defects by 38%, supporting the fab’s 2.0M 3D NAND chip monthly production goal.

LAM 810-802902-208

Related Model Recommendations

| Model Number | Product Type | Key Use Case (Complementary to LAM 810-802902-208) |

| LAM 716-028721-268 | UHV Pressure Sensor | Critical UHV input—provides 1×10⁻¹²–1×10⁻³ Torr data for TMP speed control, ensuring 3nm process stability. |

| LAM 716-027740-001 | Medium-Vacuum Sensor | Medium-vacuum input—guides roughing/backing pump operation (1×10⁻⁴–100 Torr), optimizing transition to UHV. |

| Pfeiffer TPH 600 | Turbomolecular Pump | Primary TMP paired with the controller—delivers 1×10⁻¹² Torr UHV for LAM 9000 3nm systems, optimized for speed sync. |

| Pfeiffer DUO 65 M | Dry Backing Pump | Backing pump for TMP—works with the controller to maintain 1×10⁻³ Torr backing pressure, reducing TMP wear. |

| LAM 713-071681-009 | UHV Interlock Valve | Syncs with the controller—opens/closes based on pressure data (e.g., closes if UHV drifts above 1×10⁻⁹ Torr), preventing contamination. |

| LAM 810-802902-CAL | Calibration Kit | NIST-traceable tools for pump speed/pressure control calibration, extending accuracy to 24 months. |

| LAM 203-140148-308 | Process Gas Isolation Valve | Coordinates with the controller—opens only when vacuum is stable (per sensor data), avoiding gas cross-contamination. |

| LAM 673-092355-006 | RF Feedthrough | Works with the controller via LAM PCS—if the feedthrough leaks (detected by LAM 716-028721-268), the controller increases TMP speed to maintain UHV. |

Installation, Commissioning & Maintenance Instructions

Installation Preparation & Steps

Pre-Install Compatibility Check

Confirm the controller is compatible with your LAM system (e.g., 9000 Series 3nm configuration, 2300 Series ALD) via LAM’s Part Cross-Reference Tool. Verify pump compatibility (e.g., Pfeiffer TPH 600, DUO 65 M) and sensor types (digital/analog).

For 3nm systems, ensure LAM PCS is updated to v6.2+ to support native digital sensor integration (LAM 716-027740-001, LAM 716-028721-268).

Rack & Wiring Setup

Mount the 3U rack-mount controller in a cleanroom-compatible equipment rack (maintain ≥10cm clearance from heat sources like power supplies to avoid overheating).

Wire pump connections: Use shielded cables for analog speed outputs (0–10 VDC) and twisted-pair cables for digital pump communication (RS-485). Connect E-stop wiring per SEMI S2 safety standards (ensure emergency shutdown latency ≤100 ms).

Wire sensor inputs: For LAM digital sensors, use RS-485 cables (max length 100m); for analog sensors, use 4–20 mA shielded cables to prevent EMI interference from RF equipment.

Power & Initialization

Apply 200–240 VAC power (use a dedicated circuit with surge protection). The controller will perform a self-diagnostic