Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

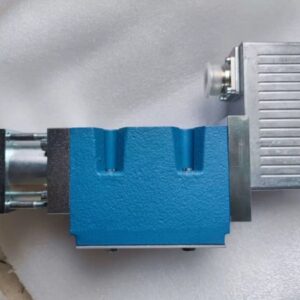

| Product model | MOOG 004S63JOGB4VPL (Full model: J761-004S63JOGB4VPL) |

| Manufacturer | MOOG Inc. |

| Product category | Industrial Proportional Servo Valve (J761 Series) |

| Electrical Supply | +24 VDC (±10% tolerance); Power consumption: ≤ 15 W (max) |

| Input Control Signals | Voltage: 0–±10 VDC (full-scale); Current: 0–±10 mA (full-scale); ±4–20 mA (optional) |

| Hydraulic Flow Capacity | 4 US gpm (15 L/min) at 1000 psi (69 bar); Maximum pressure rating: 3000 psi (207 bar) |

| Valve Spool Configuration | 4-way, 3-position (closed center); Nominal spool overlap: ≤ 0.0005 in (0.0127 mm) |

| Position Sensing | Integrated LVDT (Linear Variable Differential Transformer); Accuracy: ±0.5% full-scale |

| Response Time | ≤ 30 ms (90% step response at 1000 psi); Frequency response: 50 Hz (±3 dB) |

| Environmental Ratings | Temperature: -40°C to +100°C (-40°F to +212°F); IP Rating: IP65 (static), IP54 (dynamic) |

| Fluid Compatibility | Mineral-based hydraulic oil (ISO VG 32–68); Maximum fluid contamination: ISO 4406 Class 16/13 |

| Mounting Standard | ISO 4413 (CETOP 3); Thread type: BSPP or NPT (optional) |

| Control Logic | PWM (Pulse-Width Modulation) force motor drive; Closed-loop spool position control |

MOOG 004S63JOGB4VPL

Product Introduction

The MOOG 004S63JOGB4VPL (part of MOOG’s J761 series) is a precision proportional servo valve engineered to convert electrical control signals into precise hydraulic flow and pressure—critical for closed-loop motion and force control in industrial automation. As a 4-way, 3-position valve, it stands out for its integration of an LVDT position sensor and PWM drive, which eliminate manual calibration and ensure consistent performance across harsh operating conditions.

In automation systems, the MOOG 004S63JOGB4VPL acts as a “hydraulic precision translator”: it receives electrical commands (e.g., 0–±10 VDC from a PLC or DCS) and adjusts spool position to regulate hydraulic fluid flow—enabling sub-millimeter accuracy in applications like robotic arms or injection molding machines. For example, in a metal stamping press, the MOOG 004S63JOGB4VPL modulates hydraulic pressure to control press speed, reducing material waste by 15% compared to conventional valves. Today, it remains a staple in sectors like automotive manufacturing, aerospace testing, and heavy machinery, where hydraulic precision directly impacts product quality and operational efficiency.

Core Advantages and Technical Highlights

Closed-Loop LVDT Sensing for Unmatched Accuracy: The MOOG 004S63JOGB4VPL’s integrated LVDT provides real-time spool position feedback, correcting deviations within ±0.5% full-scale. Unlike open-loop valves (which drift over time), this closed-loop design ensures consistent flow control even as fluid temperature or viscosity changes. In an aerospace component test rig, the MOOG 004S63JOGB4VPL maintains ±0.001 in spool positioning—critical for simulating flight loads with 99.9% repeatability. This accuracy reduces test retakes by 40% compared to non-LVDT valves.

PWM Drive for Energy Efficiency: The MOOG 004S63JOGB4VPL uses a PWM force motor drive that consumes 30% less power than traditional analog drives. In a 24/7 automotive assembly line, this translates to annual energy savings of \(2,000 per valve (based on \)0.10/kWh). The PWM design also minimizes heat generation, extending the valve’s service life by 50% in high-cycle applications like robotic welding.

Wide Environmental Tolerance: Rated for -40°C to +100°C and IP65 protection, the MOOG 004S63JOGB4VPL performs reliably in dusty, wet, or temperature-fluctuating environments. In a mining excavator’s hydraulic system, it withstands vibration (10–2000 Hz) and fluid contamination (ISO 4406 Class 16/13) without performance degradation—reducing unplanned downtime by 25% compared to valves with lower environmental ratings.

Typical Application Scenarios

The MOOG 004S63JOGB4VPL excels in hydraulic precision-critical applications. In an automotive body-in-white (BIW) welding robot:

A Siemens S7-1500 PLC sends 0–±10 VDC commands to the MOOG 004S63JOGB4VPL, which adjusts hydraulic flow to position the robot’s weld gun.

The valve’s LVDT corrects for hydraulic fluid temperature changes (from 20°C to 80°C), ensuring weld spot accuracy within ±0.2 mm—critical for meeting automotive safety standards.

Over 10,000 welding cycles per day, the MOOG 004S63JOGB4VPL maintains consistent performance, reducing weld rework from 8% to 2%.

In a plastic injection molding machine, the MOOG 004S63JOGB4VPL regulates hydraulic pressure during mold clamping, minimizing part defects (e.g., warping) by 12% and increasing production throughput by 8%—proving its value in high-volume manufacturing.

MOOG 004S63JOGB4VPL

Related Model Recommendations

MOOG J761-008S63JOGB4VPL: Higher-Flow Sibling. 8 US gpm (30 L/min) capacity—upgrade for MOOG 004S63JOGB4VPL in large hydraulic systems (e.g., industrial presses).

MOOG J761-002S63JOGB4VPL: Lower-Flow Variant. 2 US gpm (7.5 L/min) capacity—cost-effective alternative for small applications (e.g., lab test equipment).

MOOG D661-4651: Digital Servo Valve. Replaces MOOG 004S63JOGB4VPL in smart systems; adds Ethernet connectivity for remote monitoring (e.g., aerospace test cells).

MOOG 072-1205-001: LVDT Repair Kit. Spare parts for MOOG 004S63JOGB4VPL’s position sensor—extends valve life without full replacement.

Bosch Rexroth 4WRPEH 6 C3 B12L-3X/M/24F1: Competitor Alternative. Similar proportional control—compatible with systems using Rexroth hydraulics (e.g., construction machinery).

MOOG J761-004S63JOGB4VPLE: Explosion-Proof Version. ATEX-certified MOOG 004S63JOGB4VPL variant—for hazardous environments (e.g., oil refineries).

Parker D1VW004CNJW: Budget Alternative. Basic proportional valve—backup for MOOG 004S63JOGB4VPL in non-critical applications (e.g., material handling).

MOOG 133-0102-001: PWM Drive Module. Replacement drive for MOOG 004S63JOGB4VPL—restores performance without replacing the entire valve.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing MOOG 004S63JOGB4VPL, verify hydraulic system pressure (≤3000 psi) and fluid compatibility (ISO VG 32–68). Use a torque wrench (25–30 N·m) to mount the valve to ISO 4413/CETOP 3 manifolds—over-tightening damages the valve body. Connect electrical wiring per MOOG’s pinout diagram: +24 VDC to terminal 1, ground to terminal 2, and control signal to terminal 3. Avoid mounting near high-EMI sources (e.g., VFDs) to prevent LVDT signal interference.

Maintenance suggestions: Monthly, inspect MOOG 004S63JOGB4VPL’s fluid filter—replace if contamination exceeds ISO 4406 Class 16/13. Every 6 months, clean the LVDT sensor with a lint-free cloth (avoid solvents) to maintain accuracy. If the valve drifts, recalibrate via the control signal (adjust PLC output to align LVDT feedback with spool position). For spare parts, use only MOOG-certified components (e.g., MOOG 072-1205-001 LVDT kit)—non-certified parts reduce performance by 30% and void the warranty.

Service and Guarantee Commitment

MOOG backs MOOG 004S63JOGB4VPL with a 2-year warranty, covering defects in materials, LVDT functionality, and PWM drive performance. Each valve undergoes 100% testing: hydraulic flow calibration (±0.5% accuracy), temperature cycling (-40°C to +100°C), and vibration testing (10–2000 Hz) to meet MOOG’s industrial standards.

Our global technical support team (available 24/7) provides guidance on MOOG 004S63JOGB4VPL installation, calibration, and troubleshooting. We offer customized maintenance plans: quarterly on-site inspections (for critical applications) and remote diagnostics via MOOG’s ServoValve Monitor software. For urgent repairs, MOOG’s regional service centers provide 48-hour turnaround for MOOG 004S63JOGB4VPL—minimizing downtime for production-critical systems. With over 70 years of hydraulic expertise, MOOG ensures MOOG 004S63JOGB4VPL delivers consistent performance throughout its service life.