Description

D138-002-012: Product Overview

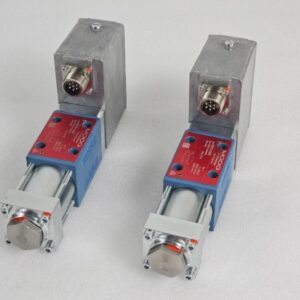

The MOOG D138-002-012 is a two-stage electrohydraulic servo valve from the D138 Series, designed for precision control of hydraulic actuators in dynamic systems requiring moderate-to-high flow rates. In an automation architecture, it serves as the critical interface between electronic controllers (e.g., PLCs, motion controllers) and hydraulic actuators (e.g., cylinders, motors), converting low-power electrical command signals into proportional hydraulic flow and pressure. The D138 Series is recognized for its balanced performance in industrial and aerospace applications, combining robust construction with millisecond-level response. This valve operates on a nozzle-flapper pilot stage and a sliding spool main stage, ensuring stable output across varying loads. The “002-012” configuration denotes a dual-channel design (two independent spool circuits) for redundant or multi-actuator control, making it suitable for complex machinery like dual-acting presses or multi-axis simulators. It is typically integrated into closed-loop systems with feedback from position/force sensors, where adjustments to the input signal maintain desired actuator behavior—essential for avoiding overshoot in high-force applications.

MOOG D138-002-012

D138-002-012: Technical Specifications

-

Model Number: D138-002-012

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Servo Valve (Two-Stage)

-

Valve Configuration: 4-way spool (symmetrical flow paths, spring-centered), dual-channel (002-012 configuration)

-

Nominal Flow: 15 GPM (56.8 L/min) @ 1000 psi (69 bar) differential pressure (per channel)

-

Maximum Pressure: 3000 psi (207 bar) per port

-

Input Signal: ±10VDC (standard), ±40mA (via optional G123 series amplifier)

-

Response Time: <20 ms (step input to 90% flow)

-

Resolution: <0.15% of full scale (hysteresis <0.6%)

-

Operating Temperature: -20°C to +80°C (-4°F to 176°F) (fluid-dependent)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), phosphate ester synthetic fluids (e.g., Skydrol)

-

Weight: 2.2 kg (4.9 lbs, valve body only)

-

Dimensions: 152mm (L) x 83mm (W) x 108mm (H) (approximate)

-

Certifications: CE, ISO 9001 (manufacturing standard), AS9100 (aerospace quality)

Core Features & Customer Value

Dual-Channel Redundancy: The 002-012 configuration provides two independent 4-way spool circuits, enabling simultaneous control of two actuators (e.g., dual-acting cylinder) or redundant actuation paths. For engineers, this eliminates single-point failure risks in critical systems like aircraft landing gear or press brakes, where loss of control could cause damage.

Moderate-Flow Precision: With 15 GPM nominal flow and <0.15% resolution, the valve delivers linear output proportional to the ±10VDC input. In material testing rigs, this ensures accurate force application (±0.5% error) for tensile/compression tests, critical for valid material property data.

Balanced Dynamic Response: A <20 ms response time allows rapid adjustment during transient conditions (e.g., sudden load changes in a hydraulic press). For industrial machinery, this minimizes actuator lag, improving cycle time efficiency by 10-15% compared to slower valves.

Rugged Construction for Industrial/Aerospace Use: The valve body is forged aluminum with a hardened spool, resisting corrosion and wear from synthetic fluids (common in aerospace) or contaminated oils (industrial environments). For maintenance teams, this extends service life to 12,000+ operating hours, reducing replacement costs.

Seamless System Integration: Native compatibility with Moog G123 amplifiers (for ±40mA signals) and 3500-series monitoring systems simplifies retrofits. The dual-channel design integrates with PLCs via analog outputs, enabling centralized control of multi-actuator systems.

MOOG D138-002-012

Typical Applications

The D138-002-012 is deployed in systems requiring dual-actuator control or moderate-flow precision:

-

Aerospace: Flight simulator dual-axis actuators (pitch/roll control), landing gear deployment (dual-cylinder synchronization).

-

Test & Simulation: Material testing machines (tension/compression with dual-load cells), fatigue rigs (cyclic loading with redundant actuators).

-

Industrial Machinery: Dual-acting hydraulic presses (blank holder + punch control), plastic injection molders (clamp + injection cylinder coordination).

-

Mobile Equipment: Excavator boom/arm control (dual-cylinder stability), agricultural tractor implement lifts.

In a dual-acting press brake, for example, the valve’s two channels control the upper and lower cylinders independently. Its <20 ms response ensures the ram follows the programmed bend angle within ±0.1°, reducing sheet metal scrap by 8%.