Description

CZ1008DVA: Product Overview

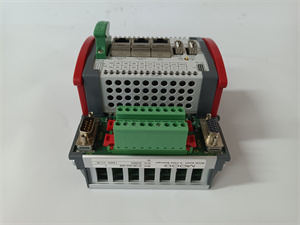

The Moog CZ1008DVA is a two-stage electrohydraulic servo valve from the CZ Series, designed for high-precision control of hydraulic actuators in dynamic systems. In an automation architecture, it serves as the critical interface between electronic controllers (e.g., PLCs, motion controllers) and hydraulic actuators (e.g., cylinders, motors), converting low-power electrical command signals into proportional hydraulic flow and pressure. The CZ Series is recognized for its robust design and millisecond-level response, making it suitable for applications requiring precise position, velocity, or force control—such as aerospace flight simulators, industrial robotics, and material testing machines. This valve operates on a nozzle-flapper pilot stage and a sliding spool main stage, ensuring stable performance across varying loads. It is typically integrated into closed-loop systems where feedback from position/force sensors adjusts the input signal to maintain desired actuator behavior, critical for avoiding overshoot or instability in high-performance machinery.

MOOG CZ1008DVA

CZ1008DVA: Technical Specifications

-

Model Number: CZ1008DVA

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Servo Valve (Two-Stage)

-

Valve Configuration: 4-way 2-position spool (symmetrical flow paths)

-

Nominal Flow: 8 GPM (30.3 L/min) @ 1000 psi (69 bar) differential pressure

-

Maximum Pressure: 210 bar (3045 psi) per port

-

Input Signal: ±40 mA (standard), compatible with ±10 VDC (via optional amplifier)

-

Response Time: <10 ms (step input to 90% flow)

-

Resolution: <0.1% of full scale (hysteresis <0.5%)

-

Operating Temperature: -20°C to +80°C (fluid-dependent)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), phosphate esters

-

Weight: 1.8 kg (valve body only)

-

Dimensions: 152mm (L) x 76mm (W) x 102mm (H) (approximate)

-

Certifications: CE, ISO 9001 (manufacturing standard)

Core Features & Customer Value

High-Precision Flow Control: The two-stage design (nozzle-flapper pilot + sliding spool) delivers linear flow output proportional to the input signal, with resolution <0.1% of full scale. For engineers, this enables micrometer-level positioning of actuators in semiconductor manufacturing equipment or wind tunnel test rigs, where accuracy directly impacts product quality.

Fast Dynamic Response: A <10 ms response time allows the valve to adjust flow rapidly during transient conditions (e.g., sudden load changes). In robotic welding arms, this minimizes lag between controller commands and torch movement, improving weld consistency.

Robust Construction for Harsh Environments: The valve body is machined from stainless steel with hardened spool lands, resisting wear from contaminated fluids (common in construction machinery). For maintenance teams, this extends service life to 10,000+ operating hours, reducing replacement costs.

Flexible Signal Compatibility: While optimized for ±40 mA inputs, it integrates with optional Moog amplifiers to accept ±10 VDC or digital (EtherCAT) signals. This adaptability simplifies retrofitting legacy systems (e.g., upgrading analog controls to digital in paper mills) without replacing the valve.

Stable Performance Across Loads: Internal feedback mechanisms compensate for pressure fluctuations, maintaining consistent flow output even when system pressure varies by ±20%. In material testing machines, this ensures accurate force application regardless of specimen stiffness.

MOOG CZ1008DVA

Typical Applications

The CZ1008DVA is deployed in systems requiring precise hydraulic actuation:

-

Aerospace: Flight simulator actuators (controlling pitch/roll/yaw), landing gear deployment systems.

-

Industrial Robotics: Welding robots (torch positioning), material handling arms (load control).

-

Test & Simulation: Hydraulic test rigs (fatigue testing of components), wind tunnel vanes (airflow control).

-

Manufacturing: Plastic injection molding machines (clamp force control), metal stamping presses (ram positioning).

In a wind tunnel facility, for example, the valve controls variable vanes to adjust airflow velocity, with its fast response ensuring test conditions stabilize within 50 ms of a command change—critical for accurate aerodynamic data collection.