Description

D061-9321: Product Overview

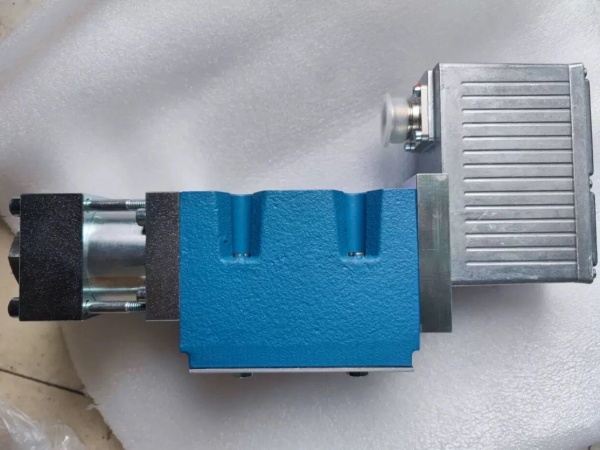

The D061-9321 is a two-stage electrohydraulic servo valve from the D061 Series, designed for stable control of hydraulic actuators in industrial systems requiring moderate precision. In an automation architecture, it functions as the interface between electronic controllers (e.g., PLCs, motion controllers) and hydraulic actuators (cylinders, small motors), converting low-power electrical command signals into proportional hydraulic flow and pressure to regulate actuator position, velocity, or force.

This valve belongs to the D061 Series, a platform characterized by its two-stage design: a nozzle-flapper pilot stage for signal amplification and a sliding spool main stage for flow modulation. This architecture ensures stable output across varying loads, making it suitable for applications where consistent performance is critical. The D061-9321 is typically integrated into closed-loop control systems with position/force feedback, where adjustments to the input signal maintain desired actuator behavior—essential for avoiding overshoot in machinery like small presses or test rigs. The D061 Series emphasizes ruggedness and compatibility with industrial hydraulic fluids, reducing integration complexity for engineers.

MOOG D634-319C

D061-9321: Technical Specifications

-

Model Number: D061-9321

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Servo Valve (Two-Stage)

-

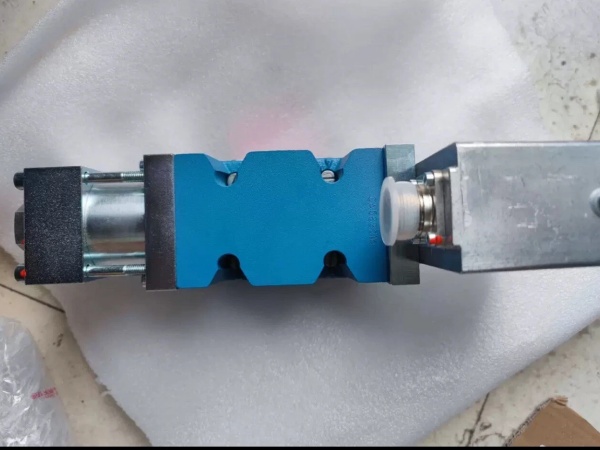

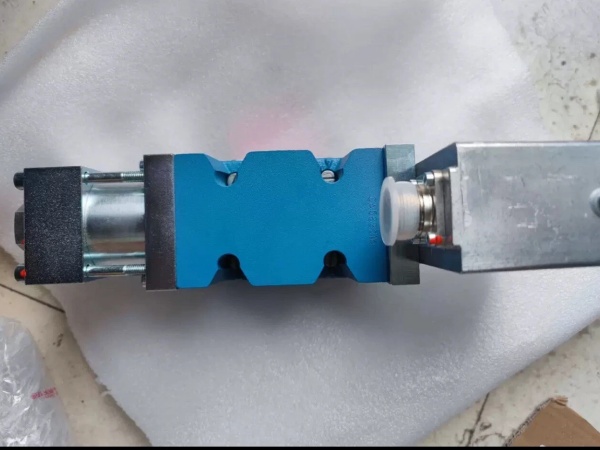

Valve Configuration: 4-way spool (symmetrical flow paths, spring-centered)

-

Nominal Flow: 4 GPM (15.1 L/min) @ 1000 psi (69 bar) differential pressure

-

Maximum Pressure: 3000 psi (207 bar) per port

-

Input Signal: ±10VDC (standard), ±40mA (via optional amplifier)

-

Response Time: <20 ms (step input to 90% flow)

-

Resolution: <0.2% of full scale (hysteresis <0.7%)

-

Operating Temperature: -20°C to +80°C (fluid-dependent)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), HFC fluids (e.g., Houghto-Safe 620)

-

Weight: 2.1 kg (4.6 lbs, valve body only)

-

Dimensions: 146mm (L) x 79mm (W) x 105mm (H) (approximate)

-

Certifications: CE, ISO 9001 (manufacturing standard)

Core Features & Customer Value

The two-stage design of the D061-9321—combining a nozzle-flapper pilot stage with a sliding spool main stage—delivers stable flow output proportional to the ±10VDC input, even under fluctuating system pressures. For engineers managing machinery like small hydraulic presses, this stability minimizes actuator drift, ensuring consistent part quality.

With a nominal flow of 4 GPM and <0.2% resolution, the valve provides adequate control for small-to-medium actuators without oversizing. The <20 ms response time allows timely adjustments during transient conditions (e.g., load changes in a material testing rig), improving cycle time predictability.

The valve’s rugged construction features a stainless steel body and hardened spool lands, resisting wear from contaminated fluids common in industrial environments. For maintenance teams, this extends service life to 10,000–15,000 operating hours, reducing replacement costs. The spring-centered spool ensures safe actuator positioning during power loss, a critical safety feature for machinery guarding.

Native compatibility with standard analog controllers (PLCs, PID loops) and optional amplifiers simplifies integration, avoiding custom signal conversion hardware. Field-replaceable spool/sleeve assemblies minimize downtime during repairs, streamlining maintenance workflows.

MOOG D634-319C

Typical Applications

The D061-9321 is applied in systems requiring stable, moderate-flow hydraulic control:

-

Small Industrial Machinery: Robotic part feeders (positioning accuracy ±0.2mm), small press brakes (bend angle control).

-

Material Testing: Low-cycle fatigue rigs (tensile/compression tests up to 5 Hz), hardness testers.

-

Laboratory Equipment: Benchtop hydraulic trainers, fluid power demonstration systems.

-

Aerospace Simulation: Auxiliary actuator control in flight simulators (e.g., canopy deployment).

In a small press brake, for example, the D061-9321 regulates ram positioning via hydraulic cylinder control. Its stable output ensures bend angles remain within ±0.5° tolerance, reducing scrap. In a university lab, it controls a fatigue test rig for polymers, with its <20 ms response accurately replicating cyclic loading profiles.