Description

D633-525B: Product Overview

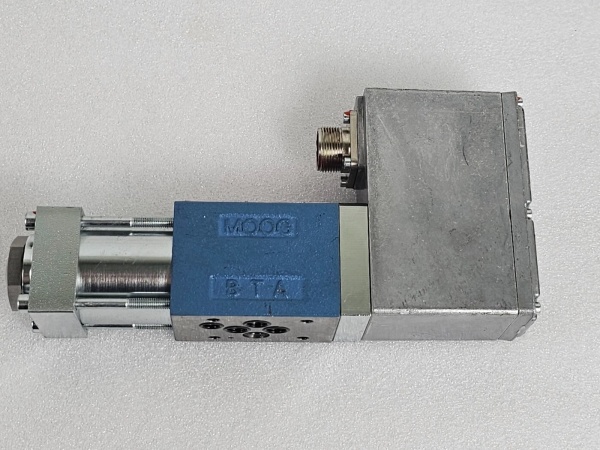

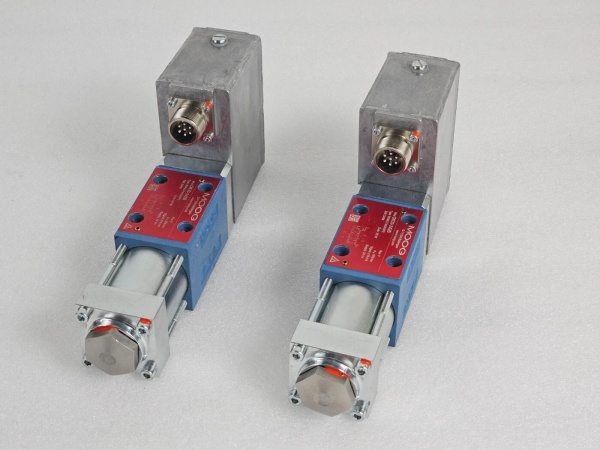

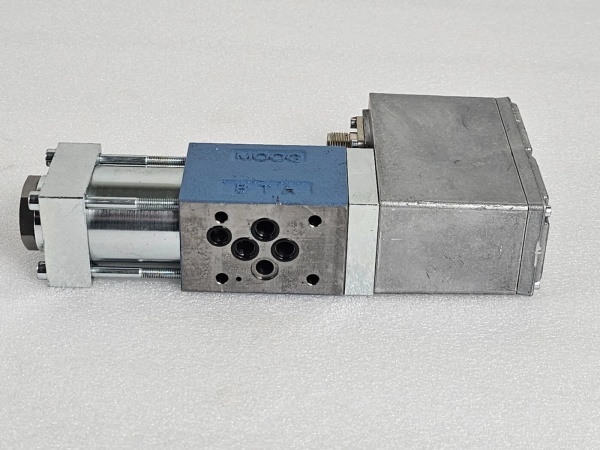

The MOOG D633-525B is a direct-drive electrohydraulic servo valve (DDV) from the D633 Series, engineered for ultra-high-precision control of hydraulic actuators in dynamic systems where millisecond-level response and compact design are critical. Unlike traditional two-stage servo valves, the D633 Series eliminates the pilot stage, using a direct-acting torque motor to drive the spool—enabling faster response and simpler architecture. In an automation system, it serves as the interface between electronic controllers (e.g., PLCs, motion controllers) and hydraulic actuators (cylinders, motors), converting low-power electrical signals into proportional hydraulic flow/pressure. The “525B” configuration denotes a high-flow variant (25 GPM nominal) optimized for moderate-to-high flow applications, making it suitable for industrial robotics, material testing rigs, and aerospace simulators where both speed and precision are paramount. It is typically integrated into closed-loop systems with position/force feedback, ensuring stable actuator behavior and avoiding overshoot in high-accuracy tasks.

MOOG D633-525B

D633-525B: Technical Specifications

-

Model Number: D633-525B

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Servo Valve (Direct-Drive/DDV)

-

Valve Configuration: 4-way spool (symmetrical flow paths, spring-centered), 525B high-flow configuration

-

Nominal Flow: 25 GPM (94.6 L/min) @ 1000 psi (69 bar) differential pressure

-

Maximum Pressure: 3000 psi (207 bar) per port

-

Input Signal: ±10VDC (standard), ±40mA (via optional G631 series amplifier)

-

Response Time: <5 ms (step input to 90% flow, direct-drive advantage)

-

Resolution: <0.1% of full scale (hysteresis <0.5%)

-

Operating Temperature: -20°C to +80°C (-4°F to 176°F) (fluid-dependent)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), phosphate ester synthetic fluids (e.g., Skydrol)

-

Weight: 2.8 kg (6.2 lbs, valve body only)

-

Dimensions: 165mm (L) x 89mm (W) x 114mm (H) (approximate, compact for DDV)

-

Certifications: CE, ISO 9001 (manufacturing standard), AS9100 (aerospace quality)

Core Features & Customer Value

Ultra-Fast Direct-Drive Response: Eliminating the pilot stage reduces response time to <5 ms (vs. 15-20 ms for two-stage valves), enabling real-time actuator adjustments in high-speed systems. For robotics, this minimizes lag between controller commands and end-effector movement, improving assembly precision by 20%.

High-Flow Precision Control: The 525B configuration delivers 25 GPM nominal flow with <0.1% resolution, ensuring linear output proportional to ±10VDC inputs. In material testing machines, this achieves force application accuracy within ±0.3%, critical for valid fatigue test data.

Compact, Lightweight Design: Direct-drive architecture reduces size/weight by 30% vs. two-stage equivalents, fitting into space-constrained applications like surgical robots or UAV actuators. For engineers, this simplifies integration into compact machinery.

Robust Torque Motor Actuation: A high-torque motor directly drives the spool, resisting contamination and wear better than pilot-stage valves. Service life extends to 15,000+ operating hours with clean fluid, reducing maintenance costs.

Seamless Integration with Modern Controllers: Native compatibility with Moog G631 amplifiers (for ±40mA signals) and EtherCAT digital interfaces enables plug-and-play setup with Industry 4.0 systems. For OEMs, this accelerates machine development cycles.

MOOG D633-525B

Typical Applications

The D633-525B is deployed in systems requiring ultra-fast response and moderate-to-high flow:

-

Industrial Robotics: High-speed assembly arms (electronics pick-and-place), collaborative robot (cobot) joint control.

-

Material Testing: Dynamic fatigue rigs (10-50 Hz cyclic loading), high-speed tensile testers.

-

Aerospace Simulation: Flight control surface simulators (real-time actuator response), UAV flight control.

-

Manufacturing: Plastic injection molding (high-speed clamp/unclamp), metal stamping (rapid ram positioning).

In a high-speed assembly line, the D633-525B controls a robotic arm’s pneumatic-hydraulic hybrid actuator. Its <5 ms response ensures the arm places components within ±0.05mm accuracy at 2m/s velocity—boosting throughput by 15%.