Description

D662-4602K: Product Overview

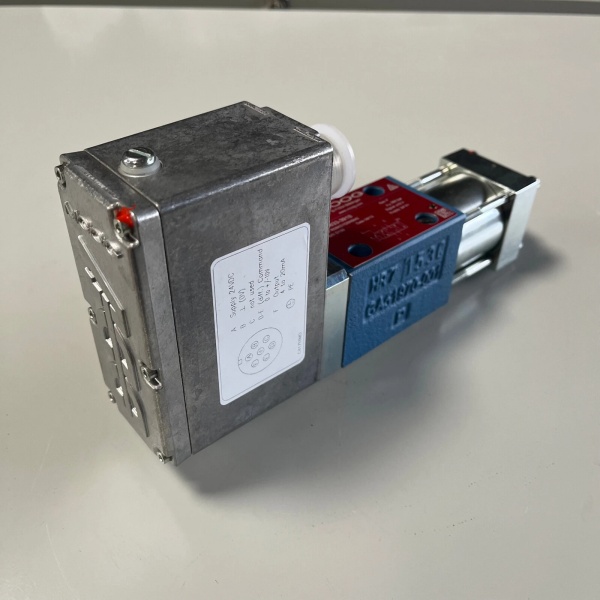

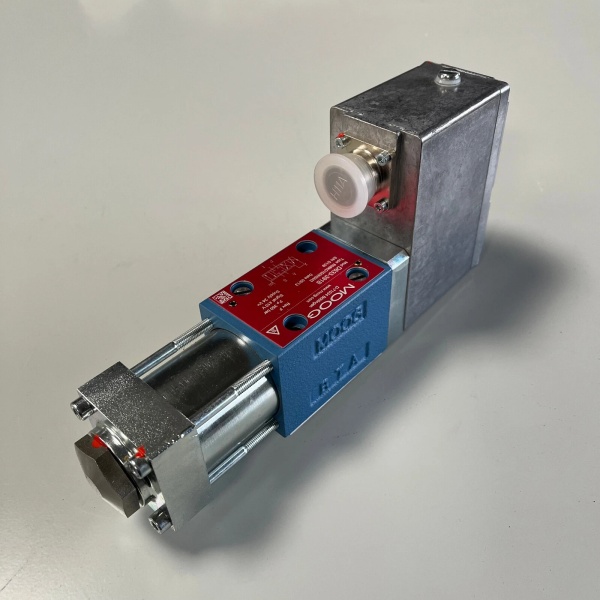

The MOOG D662-4602K is a two-stage electrohydraulic servo valve from the D662 Series, engineered for precision control of hydraulic actuators in industrial systems requiring stable performance under fluctuating load and pressure conditions. Within an automation architecture, it serves as the critical interface between electronic controllers (e.g., PLCs, motion controllers) and hydraulic actuators (cylinders, motors), converting low-power electrical command signals into proportional hydraulic flow and pressure to regulate actuator position, velocity, or force.

This valve belongs to the D662 Series, a platform distinguished by its two-stage architecture: a nozzle-flapper pilot stage for signal amplification and a sliding spool main stage for flow modulation. This design ensures stable output even under varying system pressures, a key advantage over direct-drive valves in applications with load fluctuations. The D662-4602K is typically integrated into closed-loop control systems (e.g., with position/force feedback sensors) to maintain desired actuator behavior, minimizing overshoot and ensuring consistent performance in machinery such as injection molding machines, metal forming presses, and material testing rigs. The D662 Series emphasizes ruggedness and compatibility with industrial hydraulic fluids, reducing integration complexity for engineers.

Moog D633-481B

D662-4602K: Technical Specifications

-

Model Number: D662-4602K

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Servo Valve (Two-Stage)

-

Valve Configuration: 4-way spool (symmetrical flow paths, spring-centered)

-

Nominal Flow: 12 GPM (45.4 L/min) @ 1000 psi (69 bar) differential pressure

-

Maximum Pressure: 3000 psi (207 bar) per port

-

Input Signal: ±10VDC (standard), ±40mA (via optional G123 series amplifier)

-

Response Time: <18 ms (step input to 90% flow)

-

Resolution: <0.15% of full scale (hysteresis <0.6%)

-

Operating Temperature: -20°C to +80°C (fluid-dependent)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), HFC fluids (e.g., Houghto-Safe 620)

-

Weight: 2.4 kg (5.3 lbs, valve body only, approximate)

-

Dimensions: 152mm (L) x 83mm (W) x 109mm (H) (approximate)

-

Certifications: CE, ISO 9001 (manufacturing standard), AS9100 (aerospace quality)

Core Features & Customer Value

The two-stage design of the D662-4602K—combining a nozzle-flapper pilot stage with a sliding spool main stage—delivers stable flow output proportional to the input signal, even when system pressures fluctuate. For engineers managing machinery like material testing rigs or metal forming presses, this stability minimizes actuator drift, ensuring consistent replication of cyclic loading profiles or precise part dimensions. The nozzle-flapper stage amplifies weak electrical signals to drive the main spool, while the sliding spool modulates flow with minimal hysteresis, critical for maintaining accuracy in long-term operation.

With a <18 ms response time and <0.15% resolution, the valve enables timely adjustments to command signals and precise control of small actuator movements—valuable in high-speed applications like injection molding (clamp/unclamp sequencing) or robotic assembly (end-effector positioning). The rugged construction features a stainless steel body and hardened spool lands, resisting wear from contaminated fluids common in industrial environments. For maintenance teams, this extends service life to 12,000–16,000 operating hours (with clean fluid, particle count <15 μm, β₃≥100), reducing replacement costs. Native compatibility with standard analog controllers (PLCs, PID loops) and optional G123 series amplifiers simplifies integration, while field-replaceable spool/sleeve assemblies minimize downtime during repairs. The spring-centered spool ensures safe actuator positioning during power loss, a critical safety feature for machinery guarding.

Moog D633-481B

Typical Applications

The D662-4602K is suited for industrial systems requiring stable, moderate-to-high-flow hydraulic control under variable loads:

-

Injection Molding Machines: Controls mold clamping cylinders to ensure accurate part ejection and repeatability, with stable output preventing flash or short shots.

-

Metal Forming Presses: Regulates ram positioning in medium stamping or bending machines, maintaining tight tolerances (±0.1mm) for sheet metal components.

-

Material Testing Rigs: Manages actuator movement in tensile/compression tests, delivering precise cyclic loading profiles (up to 15 Hz) for valid material property data.

-

Robotic Systems: Provides smooth motion control for robotic arms in assembly lines, ensuring consistent part placement accuracy (±0.2mm).

In a fatigue test rig for composite materials, the D662-4602K controls a hydraulic cylinder to apply cyclic loads. Its stable output ensures the cylinder follows a 5Hz sinusoidal profile within ±0.1mm displacement accuracy, critical for measuring crack propagation rates. In a medium press brake, it regulates ram positioning to maintain bend angles within ±0.5° tolerance, reducing scrap.