Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

MVME – 147A

|

|

Manufacturer

|

Motorola

|

|

Product category

|

Embedded single – board computer module

|

|

Processor

|

MC68030, typically at 33 MHz

|

|

Memory

|

4MB on – board DRAM, expandable to 32MB

|

|

Floating – point coprocessor

|

Optional MC68882

|

|

Serial ports

|

4 RS – 232

|

|

Communication interfaces

|

SCSI for storage, no built – in Ethernet in basic configs

|

|

VMEbus interface

|

Full master and slave, A32/D32 addressing

|

|

Operating temperature

|

0°C – 60°C

|

|

Storage temperature

|

– 40°C – 85°C

|

|

Dimensions

|

160mm x 233.35mm (6.3 in x 9.2 in)

|

|

Weight

|

Approximately 0.8kg

|

|

Power supply

|

+5V DC ± 5%, up to 3.5A full load

|

|

Watchdog timer

|

Integrated

|

MOTOROLA MPC2004

Product introduction

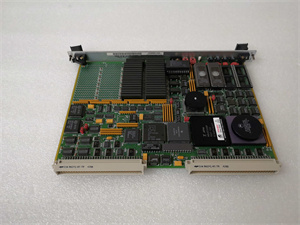

The Motorola MVME – 147A is a highly – regarded embedded single – board computer module in the industrial automation landscape. As a product of Motorola, a name synonymous with innovation and reliability in the technology domain, the MVME – 147A is designed to meet the demands of industrial control and automation systems.

At its core, the MVME – 147A features an MC68030 microprocessor, often running at 33 MHz. This provides a solid computational foundation for various industrial applications. With 4MB of on – board DRAM, expandable up to 32MB, it can handle data – intensive tasks with ease. The option to integrate an MC68882 floating – point coprocessor further enhances its numerical processing capabilities. In an industrial automation system, the MVME – 147A serves as a central processing unit, receiving data from sensors via its 4 RS – 232 serial ports, processing this data, and then sending control signals to actuators through the appropriate interfaces. Its VMEbus interface allows for seamless integration into larger industrial systems, making it an essential component for efficient industrial control.

Core advantages and technical highlights

High – performance processing

The MVME – 147A‘s MC68030 processor ensures rapid data processing. In industrial settings where real – time responses are crucial, such as in a manufacturing plant’s quality control system, it can quickly analyze data from multiple sensors. The ability to expand memory up to 32MB means it can handle increasing data volumes as industrial processes grow in complexity. The optional floating – point coprocessor enables accurate numerical calculations, which is beneficial for applications like scientific research – related industrial operations.

Versatile connectivity

Equipped with 4 RS – 232 serial ports, the MVME – 147A can interface with a wide range of legacy industrial devices. The SCSI interface provides high – speed data transfer to storage devices, ensuring efficient data storage and retrieval. Although some basic configurations lack an Ethernet interface, in setups where network connectivity is added, it can integrate with other systems for remote monitoring and control. This versatility makes it suitable for diverse industrial environments, from small – scale factories to large – scale industrial complexes.

Reliable operation

Built to withstand harsh industrial conditions, the MVME – 147A operates reliably within a temperature range of 0°C – 60°C and can be stored between – 40°C – 85°C. Its integrated watchdog timer monitors system operation and can automatically reset the module in case of malfunctions, minimizing downtime. The use of high – quality components in its construction ensures consistent performance over time, making it a trusted choice for industrial applications where reliability is of utmost importance.

MOTOROLA MPC2004

Typical application scenarios

Factory automation

In factory environments, the Motorola MVME – 147A plays a pivotal role in controlling automated production lines. It can receive data from sensors that monitor product position, speed, and quality on conveyor belts. Based on this data, it sends control signals to robotic arms, motors, and other actuators to adjust the production process. For example, in a food processing factory, it can regulate the filling levels of packaging machines, ensuring product quality and minimizing waste. It also communicates with human – machine interfaces (HMIs) to provide operators with real – time status updates and allow for manual overrides when necessary.

Industrial monitoring and control systems

In large – scale industrial plants, such as power generation facilities or chemical plants, the MVME – 147A is an integral part of monitoring and control systems. It interfaces with sensors that measure critical parameters like temperature, pressure, and flow rates. By continuously analyzing this data, it can detect anomalies and trigger alarms or initiate corrective actions. In a power plant, it can monitor the performance of turbines and generators, adjusting their operation to optimize power output and prevent equipment failures. Its ability to handle multiple data streams and execute complex control algorithms makes it essential for ensuring the safe and efficient operation of industrial processes.

Test and measurement equipment

In the field of test and measurement, the MVME – 147A is used in equipment that requires precise data processing and control. It interfaces with various test sensors and instruments, collects data, and performs calculations to analyze test results. In a laboratory setting where electronic components are being tested for performance, the MVME – 147A can control the test setup, acquire data from measurement devices, and determine if the components meet the required specifications. Its reliable performance and processing capabilities make it suitable for applications where accuracy and repeatability are crucial.

Related model recommendations

MVME147S

It is closely related to the MVME – 147A. Some versions come with an Ethernet interface, which the basic MVME – 147A may lack. Ideal for applications needing network – based communication, like modern industrial IoT setups.

MVME147SRF

Belongs to the same product family. May have optimizations for specific industrial environments, especially those relying heavily on serial – based device connectivity.

MVME147 – 013A

An upgrade option with increased memory capacity out – of – the – box. Suited for applications with high data – storage and processing requirements, such as high – resolution image processing in industrial inspection.

MVME162 – 012

Uses a different processor (MPC7457) and offers higher processing performance. For applications demanding extreme computing power, like high – speed data analytics in large – scale industrial networks.

MVME5100

Part of a more modern product line. Features advanced interfaces like Gigabit Ethernet, PCI – X, and USB, along with a powerful integrated processor. A great upgrade path for applications outgrowing the MVME – 147A capabilities, especially in Industry 4.0 initiatives.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Motorola MVME – 147A, ensure the installation area is clean, dry, and free of excessive dust. The ambient temperature should be within the 0°C – 60°C operating range. Use anti – static wrist straps and appropriate tools to handle the module, as static electricity can damage its sensitive components. When installing in a VMEbus system, make sure the VMEbus backplane is properly configured and powered off. Gently but firmly insert the MVME – 147A into the VMEbus slot, ensuring a secure connection. Connect the power supply cables according to the wiring diagram, double – checking that the +5V DC power is within the ± 5% tolerance range. Also, ensure all external devices connected via serial ports or the SCSI interface are properly configured and powered.

Maintenance suggestions

Regularly inspect the MVME – 147A for physical damage, such as bent pins or signs of overheating. Clean the module with a static – free, dry cloth to remove dust. Periodically run diagnostic software to test the functionality of serial ports, the SCSI interface, and other components. If issues arise, first check physical connections and the power supply. When replacing components, such as memory modules or connectors, use genuine Motorola parts to maintain reliability and compatibility. Keep a record of all maintenance activities for future reference.

Service and guarantee commitment

Motorola stands firmly behind the Motorola MVME – 147A. Each module undergoes strict quality control during manufacturing to meet international standards. Motorola offers a comprehensive warranty covering any manufacturing defects. In case of issues within the warranty period, Motorola’s global technical support team is readily available. They can provide detailed installation guidance, efficient troubleshooting, and maintenance advice. Motorola also invests in continuous research and development, and may release software updates to enhance the module’s functionality and compatibility. The company provides extensive documentation, including user manuals and technical guides, to help users maximize the module’s potential. This commitment reflects Motorola’s confidence in the product’s quality and its dedication to customer satisfaction in the industrial control field.