Description

Detailed Parameter Table

| Parameter name | Parameter value |

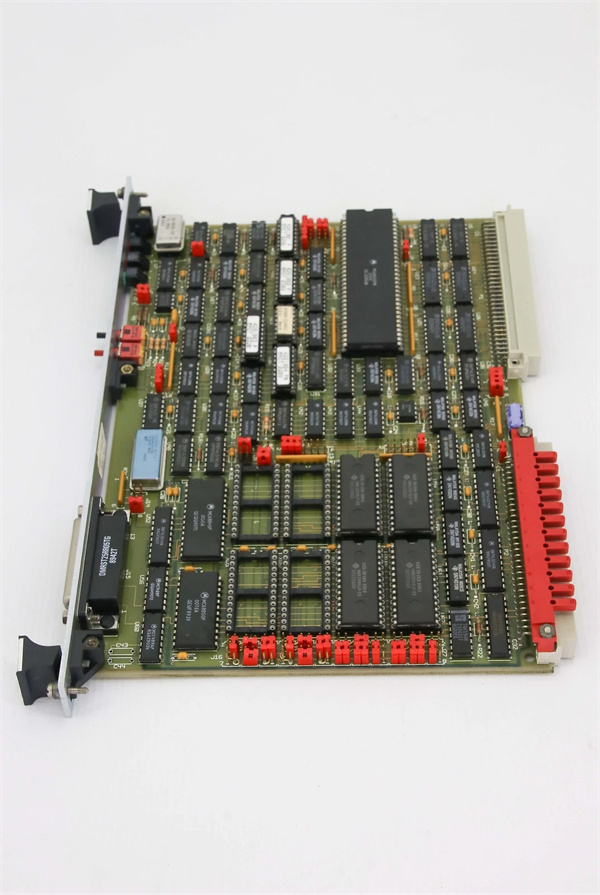

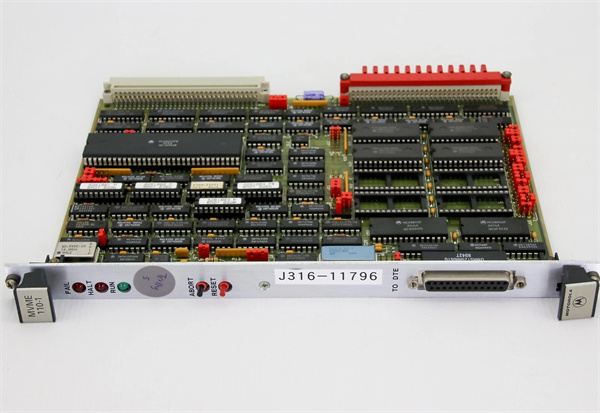

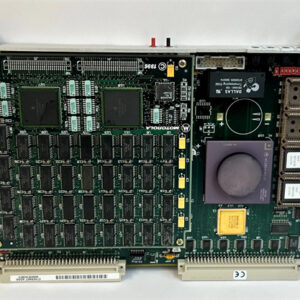

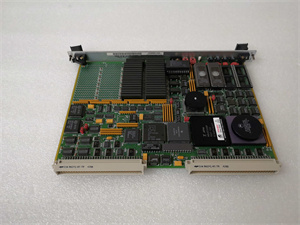

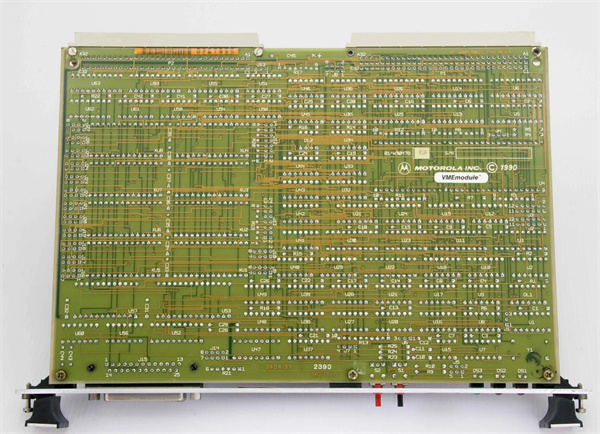

| Product model | MVME-110-1 |

| Manufacturer | Motorola (now integrated into Emerson’s industrial automation product portfolio) |

| Product category | Industrial Memory Module (VMEbus-compatible, DRAM expansion) |

| Memory Type | 16-bit DRAM (Dynamic Random Access Memory) with parity checking |

| Memory Capacity | Base: 1 MB; Expandable up to 4 MB via on-board DIP switches |

| Memory Speed | 100 ns access time (supports high-speed data read/write operations) |

| Bus Compatibility | Complies with VMEbus IEEE 1014-1987 standard (3U form factor); supports VMEbus A16/D16 and A24/D16 address/data cycles |

| Parity Support | Odd parity checking for all memory locations; parity error detection and interrupt generation |

| Environmental Requirements | Operating temperature: 0°C to 60°C (32°F to 140°F); Storage temperature: -40°C to 85°C (-40°F to 185°F); Relative humidity: 5% to 95% (non-condensing); Vibration resistance: 10-500 Hz, 1.0 g (rms) |

| Physical Size | 3U VMEbus form factor (100 mm x 160.02 mm / 3.94 in x 6.30 in); weight: 150 g (0.33 lbs) |

| Installation Method | VMEbus backplane mounting; compatible with 3U/6U VME chassis; requires VMEbus standard power supply (+5V, ±12V) |

| Diagnostic Features | Parity error LED indicator; VMEbus interrupt request (IRQ) for parity errors; self-test function on power-up |

| Power Consumption | Typical: 5 W (at 25°C, 1 MB capacity); Maximum: 8 W (at 25°C, 4 MB capacity) |

| Compatibility | Optimized for MVME series single-board computers (e.g., MVME-147-023, MVME-162-001); supports most VMEbus-based industrial controllers |

| Operating System Support | Compatible with VxWorks, OS-9, Motorola RTOS; no additional drivers required (recognized natively by MVME SBCs) |

Motorola MVME-110-1

Product Introduction

The Motorola MVME-110-1 is a high-reliability industrial memory module developed by Motorola—a leader in legacy industrial automation hardware—and now part of Emerson’s trusted product ecosystem. As a key component of the MVME series, it is engineered to address the memory expansion needs of VMEbus-based control systems, providing stable, high-speed DRAM storage for critical industrial data.

Designed for applications requiring reliable data processing and temporary data storage, the Motorola MVME-110-1 offers flexible memory capacity (1 MB to 4 MB) and parity checking to ensure data integrity. In automation architectures, the Motorola MVME-110-1 works seamlessly with MVME series single-board computers (such as the MVME-147-023 and MVME-162-001): it acts as an external DRAM expansion, enabling the SBC to handle larger datasets (e.g., real-time sensor readings, control logic variables) and run more complex industrial applications without memory bottlenecks. Its parity error detection and interrupt capabilities protect against data corruption—critical for safety-critical industries like power generation and oil and gas, where data errors can lead to operational failures or safety hazards.

Core Advantages and Technical Highlights

Flexible Memory Expansion for Scalable Performance: The Motorola MVME-110-1 offers expandable memory capacity (1 MB to 4 MB) via easy-to-configure DIP switches, eliminating the need to replace the entire module when higher memory is required. For example, a manufacturing plant using the MVME-147-023 SBC can start with 1 MB of MVME-110-1 memory for basic machine control, then expand to 4 MB as it adds more sensors or complex control algorithms. This scalability reduces upfront costs and extends the module’s lifecycle, aligning with the long service life of legacy industrial systems.

Parity Checking for Uncompromised Data Integrity: A standout feature of the Motorola MVME-110-1 is its odd parity checking for all memory locations. This function detects data corruption caused by electrical interference or memory cell failures, then triggers a VMEbus interrupt to alert the central SBC. Unlike non-parity memory modules that may silently store incorrect data (leading to unplanned downtime), the Motorola MVME-110-1 ensures data accuracy—essential for applications like oil and gas pipeline monitoring, where incorrect pressure or flow data could result in safety incidents. The parity error LED also provides visual feedback, making it easy for technicians to identify and resolve issues quickly.

Seamless VMEbus Integration and Wide Compatibility: The Motorola MVME-110-1 is fully compliant with the VMEbus IEEE 1014-1987 standard, ensuring plug-and-play integration with MVME series SBCs and other VMEbus-based controllers. It supports both A16/D16 and A24/D16 address/data cycles, enabling compatibility with older (A16) and newer (A24) VMEbus systems. Additionally, it is recognized natively by popular industrial operating systems (e.g., VxWorks, OS-9) without the need for custom drivers, simplifying installation and commissioning. For users with mixed MVME hardware, this compatibility eliminates integration headaches and ensures consistent performance across the control system.

Typical Application Scenarios

The Motorola MVME-110-1 excels in industrial settings where VMEbus-based controllers require additional memory for data-intensive tasks, such as power generation, oil and gas, and industrial robotics. In coal-fired power plants, it is deployed alongside the MVME-147-023 SBC to expand memory for real-time process monitoring. The Motorola MVME-110-1 stores large volumes of data from boiler temperature sensors, turbine speed encoders, and generator voltage monitors, enabling the SBC to run complex control algorithms that regulate boiler pressure and turbine output. Its parity checking ensures that critical operational data (e.g., turbine speed) is not corrupted by electrical interference from nearby generators, preventing costly shutdowns or equipment damage.

In oil and gas upstream operations (e.g., offshore drilling platforms), the Motorola MVME-110-1 is used with the MVME-162-001 SBC to support data logging and control logic. The module’s 4 MB expandable capacity stores drilling parameters (e.g., torque, depth, mud flow rate) for real-time analysis, while its wide operating temperature range (0°C to 60°C) withstands the harsh offshore environment. Parity error detection protects against data corruption from saltwater-induced electrical interference, ensuring accurate drilling data is transmitted to onshore control centers. For drilling operators, this reliability reduces the risk of wellbore instability or equipment failure.

In industrial robotics (e.g., automotive paint shop robots), the Motorola MVME-110-1 expands the memory of the MVME-147-023 SBC to run complex motion control programs. The module stores robot path coordinates, paint flow rates, and sensor calibration data, enabling the SBC to execute precise, multi-axis movements. Its 100 ns memory speed ensures fast data access—critical for high-speed robotic operations (e.g., painting 60 cars per hour), where delays could cause paint defects. The Motorola MVME-110-1’s vibration resistance also withstands the mechanical stress of robotic arm movements, ensuring consistent performance in 24/7 production environments.

Related Model Recommendations

Motorola MVME-110-2: A sibling model in the MVME-110 series, with base 2 MB memory (expandable up to 8 MB). It is a higher-capacity alternative to the Motorola MVME-110-1 for data-intensive applications (e.g., large-scale data logging).

Motorola MVME-147-023: A complementary MVME series SBC optimized for use with the Motorola MVME-110-1. The MVME-147-023 uses the module’s DRAM expansion to handle larger control programs and datasets.

Motorola MVME-162-001: A high-performance SBC that pairs with the Motorola MVME-110-1. Its faster 68060 processor (66 MHz) leverages the module’s 100 ns memory speed for high-speed data processing.

Motorola MVME-121: A digital I/O module that works with the Motorola MVME-110-1 and MVME SBCs. It provides discrete I/O channels, while the MVME-110-1 stores I/O status data and control logic.

Motorola MVME-1331: An industrial communication module compatible with the Motorola MVME-110-1. It transmits data stored in the MVME-110-1 to upper-level SCADA systems via RS-485/RS-232.

Motorola MVME-111: A non-volatile memory module (EPROM/Flash) that complements the Motorola MVME-110-1. It stores boot code and permanent control programs, while the MVME-110-1 provides temporary DRAM storage.

Motorola MVME-177-001: An analog I/O module that integrates with the Motorola MVME-110-1 and MVME SBCs. It collects analog sensor data, which is then stored and processed using the MVME-110-1’s memory.

Motorola MVME-110-0: A basic variant of the Motorola MVME-110-1, with fixed 1 MB memory (non-expandable). It is a cost-effective option for simple applications with minimal memory needs.

Motorola MVME-110-1

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-110-1, verify the VMEbus chassis supports 3U modules and provides stable +5V/±12V power (use a multimeter to check voltage tolerance within ±5%). Gather tools: anti-static wristband (to protect memory chips from electrostatic damage), Phillips screwdriver (for chassis mounting), and a DIP switch tool (to configure memory capacity). Set the on-board DIP switches to the desired memory capacity (1 MB, 2 MB, or 4 MB) per the product manual—incorrect settings may cause the module to be unrecognized. Ensure the chassis is powered off, clean the VME backplane connector with a dry brush to remove dust, then align the Motorola MVME-110-1 with the chassis’ guide rails and slide it gently into the backplane until fully seated. Secure with screws (torque to 0.4 N·m to avoid board damage).

Maintenance suggestions: For daily upkeep of the Motorola MVME-110-1, inspect the parity error LED weekly—steady green indicates normal operation, while a blinking red LED signals a parity error (check the connected SBC for error logs). Clean the module’s surface monthly with compressed air (low pressure, 25-30 PSI) to remove dust, which can cause overheating. If the module is unrecognized by the SBC, first recheck the DIP switch settings and reseat the module in the backplane—loose connections are a common issue. Store spare Motorola MVME-110-1 modules in anti-static bags in a climate-controlled environment (15°C to 25°C, 40% to 60% humidity) to preserve memory chip performance. Avoid exposing the module to extreme temperatures or moisture, as this can degrade DRAM cell reliability over time.

Service and Guarantee Commitment

The Motorola MVME-110-1 is backed by a 12-month factory warranty (extendable to 36 months via premium service contracts), covering defects in materials and workmanship—including faulty DRAM chips, parity error detection failures, and DIP switch malfunctions. If a defect is identified during the warranty period, we provide free replacement or repair (with a 48-hour turnaround for in-stock modules) to minimize operational downtime.

Our technical support team offers 24/7 assistance via email and online portals, staffed by engineers specialized in MVME series memory modules. They can help with Motorola MVME-110-1 configuration (e.g., DIP switch setup for memory expansion), troubleshooting parity errors, and verifying compatibility with MVME SBCs. For legacy users, we maintain a stock of critical components (e.g., 100 ns DRAM chips, parity check circuits) to support long-term maintenance. We also offer on-site commissioning services, where technicians visit your facility to test the Motorola MVME-110-1’s memory performance, verify parity functionality, and ensure seamless integration with your VMEbus system. Our commitment to the Motorola MVME-110-1 extends beyond the sale—we strive to keep your industrial control systems running reliably, so you can focus on optimizing operational efficiency.