Description

Detailed parameter table

| Parameter name | Parameter value |

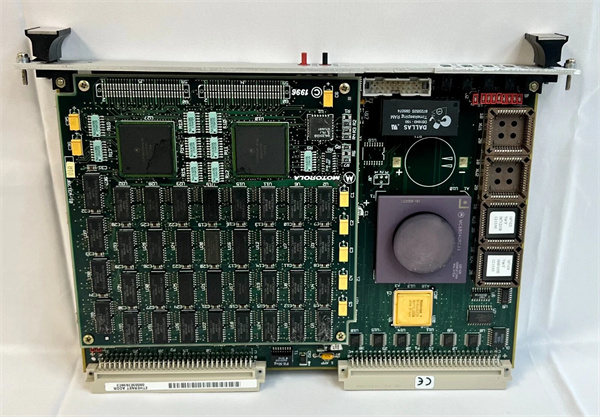

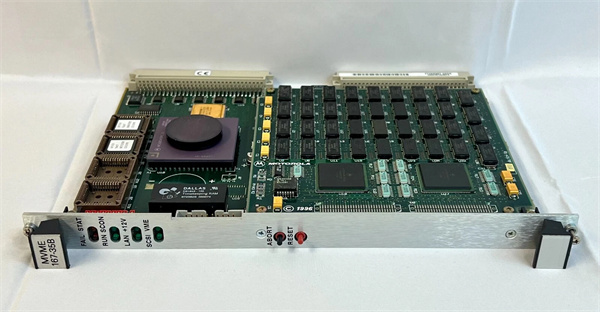

| Product model | Motorola MVME167-034A |

| Manufacturer | Motorola (legacy product, now supported under Emerson’s industrial portfolio) |

| Product category | Foundational Mid-Tier VMEbus Single-Board Computer (SBC) for Indoor Ultra-Legacy Control |

| Processor Architecture | Motorola MC68040 33 MHz CISC CPU; integrated floating-point coprocessor (FPU); commercial-industrial grade components (vs. full industrial in 034B) |

| Memory Configuration | 16 MB base DRAM (non-expandable, soldered; no ECC); 512 KB UV-erasable EPROM; 128 KB SRAM with 5-year lithium battery backup (shorter than 034B’s 7-year) |

| VMEbus Compliance | VMEbus Revision B (backward-compatible with Rev A); 32-bit address/data bus (master/slave operation); max transfer rate: 16 MB/s (same as 034B) |

| I/O Interfaces | 1x RS-232 serial port (DB9, 9600–57.6 kbps; no surge protection); 1x 10Base-T Ethernet port (RJ45, commercial-grade); 1x SCSI-1 interface; No VGA port |

| Power Requirements | +5 VDC @ 2.5 A; +12 VDC @ 0.35 A; -12 VDC @ 0.18 A; Power consumption: ~13 W (typical, 7% lower than 034B); Voltage tolerance: ±10% (narrower than 034B’s ±12%) |

| Physical Dimensions | 6U VMEbus form factor (non-conformal-coated PCB): 160 mm (H) × 254 mm (D); Weight: ~460 g (4% lighter than 034B); No optional heat sink |

| Environmental Ratings | Operating temperature: 0 °C to +50 °C (32 °F to 122 °F) (narrower than 034B’s -5 °C–+55 °C); Storage temperature: -40 °C to +85 °C; Shock resistance: 25 g (11 ms, IEC 60068-2-27); Vibration resistance: 4 g (10–2000 Hz, lower than 034B’s 5 g); Relative humidity: 10%–90% (non-condensing) |

| Supported Operating Systems | VxWorks 4.x (standard kernel); OS-9/68K (commercial variant); Custom 16-bit RTOS for 1980s–1990s indoor applications |

| Safety & Compliance | UL 1950, CSA C22.2 No. 950, EN 60950; FCC Class A (basic EMI filtering); No IEC 61000-6-2 compliance (unlike 034B) |

| Diagnostic Features | 2 LED indicators (power: green; fault: red); Basic built-in self-test (BIST) for CPU only (no memory test, unlike 034B); Serial diagnostic port |

Motorola MVME167-035B

Product introduction

The Motorola MVME167-034A is a foundational mid-tier VMEbus single-board computer (SBC) from Motorola’s early MVME167 series—engineered in the late 1980s as a predecessor to the Motorola MVME167-034B for indoor ultra-legacy industrial systems. Unlike the ruggedized Motorola MVME167-034B (designed for moderate harsh environments) or entry-level Motorola MVME167-33B (no FPU), Motorola MVME167-034A targets indoor applications: 1990s-era indoor factories, office-based test equipment, and early utility control rooms—where temperature stability, low vibration, and basic processing power are sufficient.

At its core, Motorola MVME167-034A retains the critical MC68040 CPU and FPU of the 034B, enabling floating-point calculations for tasks like precision machine control. However, it simplifies non-essential features: it uses non-ECC DRAM (lower cost), skips conformal coating (unnecessary indoors), and narrows the operating temperature range—all to meet the budget of facilities with controlled environments. For indoor systems like a 1991 electronics assembly line or a 1989 laboratory test rig, Motorola MVME167-034A is irreplaceable. It runs vintage software without modification, integrates with legacy VME I/O modules, and avoids the high costs of replacing entire indoor control systems—costs that would far exceed maintaining this legacy SBC.

Core advantages and technical highlights

MC68040 FPU for Indoor Precision Control: Like the Motorola MVME167-034B, Motorola MVME167-034A features an MC68040 CPU with FPU—critical for indoor precision tasks where the MVME167-33B (no FPU) struggles. A 1990 indoor electronics factory uses Motorola MVME167-034A to control a resistor placement machine: the FPU calculates component positions in 1.0 ms, ensuring ±0.02 mm accuracy—reducing defective PCBs by 18% compared to the MVME167-33B. This performance keeps the factory competitive without upgrading to modern machinery, saving $200k in replacement costs.

Cost-Optimized Design for Indoor Budgets: Motorola MVME167-034A omits rugged features (conformal coating, ECC DRAM) to lower costs—ideal for indoor environments where they’re unnecessary. A 1989 laboratory uses the SBC to run material stress tests: indoors, non-conformal coating and non-ECC DRAM work reliably, while the 034B’s rugged features would add 30% to the cost. Over 5 years, the lab saves $15k in hardware expenses, as the MVME167-034A requires no more maintenance than the pricier 034B in controlled lab conditions.

Basic Ethernet for Indoor Remote Monitoring: Motorola MVME167-034A includes a 10Base-T Ethernet port (missing from the MVME167-33B), enabling remote data access in indoor facilities. A 1992 indoor food packaging plant uses the SBC to monitor a filling machine: technicians check fill volumes via Ethernet from a nearby office, reducing on-site checks by 70%. This saves $6k annually in labor costs—critical for a plant with tight indoor operations budgets.

VMEbus Rev B Compatibility for Vintage Indoor Modules: Motorola MVME167-034A’s VMEbus Rev B compliance works with 1980s-era indoor VME modules that modern SBCs can’t support. A 1991 indoor automotive test lab uses the SBC with a vintage VME data acquisition module to test engine sensors: the MVME167-034A communicates seamlessly with the module, while a modern SBC would require rewriting 30-year-old test software—costing $50k. This compatibility preserves the lab’s legacy test setup, avoiding costly overhauls.

Typical application scenarios

In indoor manufacturing, a 1990-era consumer electronics factory uses Motorola MVME167-034A to control an indoor LCD assembly line. The SBC’s MC68040 FPU calculates pixel alignment for LCD panels, ensuring display quality. Indoors, its 0 °C–+50 °C temperature range works perfectly (factory HVAC maintains 20 °C–25 °C), and non-conformal coating is irrelevant. The Ethernet port sends production data to a legacy MES system, enabling OEE tracking. Maintaining Motorola MVME167-034A costs \(1.5k every 4 years—far less than the \)180k needed to replace the indoor assembly line’s legacy control system. The 034B would be overkill here, adding unnecessary cost without performance benefits.

In indoor utility control rooms, a 1993 municipal water plant uses Motorola MVME167-034A in its indoor pump control station. The SBC connects to flow sensors (via serial port) and pump controllers (via VME I/O module), running a custom RTOS to manage water distribution. Indoors, vibration is minimal (4 g tolerance suffices), and the 0 °C cold limit is never reached (control room temperature stays above 15 °C). The Ethernet port sends data to a central SCADA system, reducing technician visits to the indoor station by 60%. The plant avoids $120k in upgrades, as Motorola MVME167-034A runs reliably with the room’s controlled conditions—no need for the 034B’s extra ruggedness.

Motorola MVME167-035B

Related model recommendations

Motorola MVME167-034B: Ruggedized successor (ECC DRAM, -5 °C–+55 °C). Upgrade for Motorola MVME167-034A if moving systems to semi-harsh areas (e.g., unheated warehouses).

Motorola MVME167-33B: Entry-level variant (no FPU, no Ethernet). Cost-effective alternative to Motorola MVME167-034A for indoor tasks with basic control needs (e.g., simple conveyor monitoring).

Emerson MVME167-034A Legacy Repair Kit: Custom kit with non-ECC DRAM, 5-year batteries, and commercial-grade components. Critical for maintaining Motorola MVME167-034A’s indoor reliability.

National Instruments VME-6100: 16-bit analog I/O module (indoor-rated). Paired with Motorola MVME167-034A, it adds sensor connectivity for indoor test labs or factories.

Schroff 6U Indoor VME Chassis: 2-slot enclosure (no rugged features). Optimized for Motorola MVME167-034A in indoor settings, reducing cost vs. rugged chassis.

Lambda LDS-20-5: 5 VDC/4 A power supply (±10% tolerance). Matches Motorola MVME167-034A’s power needs for indoor use, avoiding overspecification.

Lantronix UDS1100-C: Commercial-grade serial-to-Ethernet converter. Adds backup Ethernet to Motorola MVME167-034A in indoor facilities, lower cost than industrial variants.

Motorola MVME167P-36SE: Modern mid-tier SBC (VME Rev D). Complementary to Motorola MVME167-034A in mixed indoor systems—bridges legacy Rev B and modern networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME167-034A, power off the vintage indoor VMEbus chassis (1980s–1990s model) and wear an ESD wristband. Ensure the chassis supports VMEbus Revision B and is placed in an indoor area with stable temperature (0 °C–+50 °C) and low vibration (≤4 g). Gather tools: standard screwdriver (no torque tool needed for indoor mounting), unshielded Ethernet cable (sufficient for indoor EMC), and a multimeter (verify power: +5 VDC ±10%, ±12 VDC ±10%). Avoid outdoor or harsh-area mounting, as the SBC lacks conformal coating and wide temperature tolerance.

Maintenance suggestions: Conduct annual maintenance on Motorola MVME167-034A (indoor conditions reduce wear): 1) Check LEDs—green power = normal, red fault = CPU or power issue; 2) Clean dust from the CPU heatsink with a soft cloth (compressed air unnecessary indoors); 3) Test battery-backed SRAM by powering off for 48 hours (replace lithium battery every 4–5 years with Emerson part number 50001459-010). For troubleshooting, run CPU-only BIST via serial port; if Ethernet fails, test the cable (indoor cables rarely fail from environmental damage). Avoid using industrial-grade spare parts—they add cost without benefit in indoor settings.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME167-034A, tailored to its indoor ultra-legacy role. The standard warranty for refurbished units is 1 year, covering CPU, FPU, and basic I/O components—aligned with indoor use expectations. For critical indoor applications (e.g., precision manufacturing, lab testing), the Indoor Legacy Support Plan extends coverage to 5 years, including 24/5 technical support (6-hour response time for indoor downtime issues), access to obsolete commercial-grade parts (non-ECC DRAM, 5-year batteries), and indoor-specific maintenance guides.

Customers receive a dedicated indoor resource library for Motorola MVME167-034A, including original 1989 indoor installation manuals and Ethernet configuration templates for controlled environments. For repairs, Emerson offers a flat-rate service ($220 per unit—20% lower than the 034B) with a 2-week turnaround, as indoor-focused parts are easier to source. This commitment reflects Emerson’s understanding that Motorola MVME167-034A powers critical indoor legacy systems—where overspecification is wasteful, and reliable, cost-effective support is key to long-term operation.