Description

Detailed Parameter Table

| Parameter name | Parameter value |

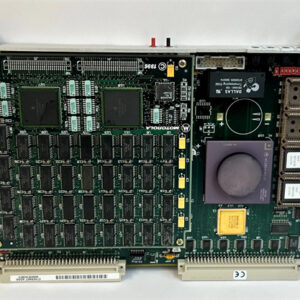

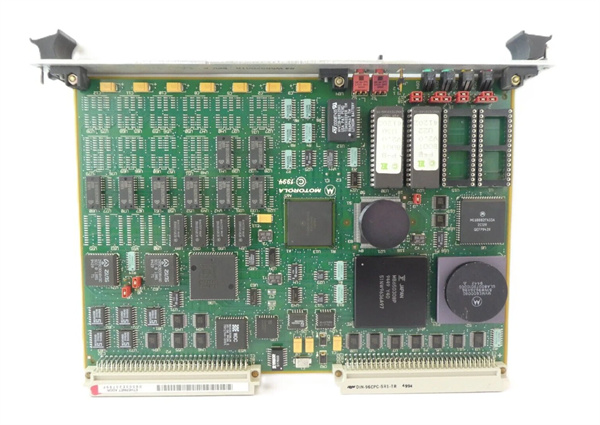

| Product model | MVME-147-023 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product category | Industrial Single-Board Computer (SBC) |

| Processor | Motorola 68040 32-bit microprocessor, operating at 25 MHz |

| Memory | 4 MB DRAM (expandable up to 16 MB) with parity checking; 512 KB EPROM for boot code |

| I/O Interfaces | 2 x RS-232 serial ports (DB-9 connectors); 1 x parallel port (Centronics-style); 1 x SCSI-2 interface (for external storage) |

| Communication Protocol | Supports ASCII, RTU mode for serial communication; compatible with Modbus protocol via software configuration |

| Environmental Requirements | Operating temperature: 0°C to 60°C (32°F to 140°F); Storage temperature: -40°C to 85°C (-40°F to 185°F); Relative humidity: 5% to 95% (non-condensing) |

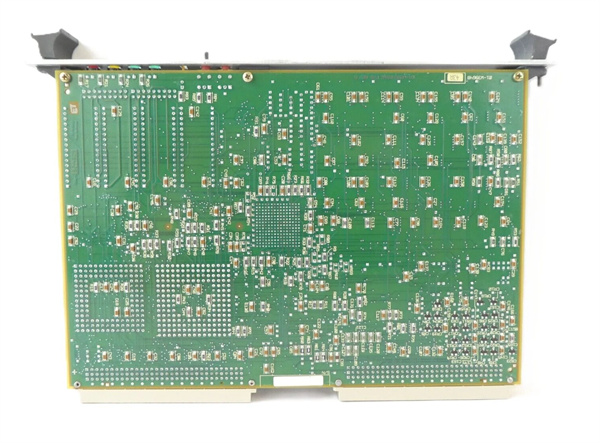

| Physical Size | 6U VMEbus form factor (233.35 mm x 160.02 mm / 9.19 in x 6.30 in); complies with IEEE 1014-1987 standards |

| Installation Method | VMEbus backplane mounting (3U/6U VME chassis compatible); requires standard VMEbus power supply (±5V, ±12V) |

| Performance Indicators | Instruction cycle time: 40 ns (for basic arithmetic operations); Data transfer rate: Up to 10 MB/s via SCSI interface; MTBF (Mean Time Between Failures): > 100,000 hours at 40°C |

| Power Consumption | Typical: 12 W (at 25°C, full load); Maximum: 15 W |

| Operating System Support | Compatible with VxWorks, OS-9, and Motorola’s proprietary RTOS (Real-Time Operating System) for industrial control |

Motorola MVME-147-023

Product Introduction

The Motorola MVME-147-023 is a high-reliability industrial single-board computer (SBC) developed by Motorola, a pioneer in industrial automation hardware, and now part of Emerson’s trusted industrial portfolio. As a key model in the MVME-147 series, it is designed specifically for mission-critical industrial control applications that demand stable performance, robust connectivity, and long-term operational reliability.

At its core, the Motorola MVME-147-023 leverages the powerful Motorola 68040 32-bit microprocessor, delivering efficient data processing capabilities to handle real-time control tasks in complex automation systems. Its integration of expandable memory, multiple I/O interfaces, and SCSI storage support makes it a versatile solution for bridging legacy industrial equipment with modern control systems. In automation architectures, the Motorola MVME-147-023 acts as a central processing unit (CPU) for VMEbus-based control systems, enabling seamless data collection, processing, and communication between sensors, actuators, and upper-level management software—critical for maintaining operational efficiency in industrial environments.

Core Advantages and Technical Highlights

Legacy Compatibility with Modern Utility: The Motorola MVME-147-023 excels in supporting legacy industrial systems, a common pain point for facilities with long-serving automation infrastructure. It maintains full compatibility with VMEbus backplanes (a widely used standard in older industrial setups) while offering expandable memory and flexible OS support (e.g., VxWorks) to adapt to updated control logic. This means plants can extend the lifecycle of existing equipment without full system overhauls, reducing capital expenditure.

Robust Industrial-Grade Reliability: Built to withstand harsh industrial conditions, the Motorola MVME-147-023 features a ruggedized design with strict environmental compliance—operating seamlessly in temperature ranges from 0°C to 60°C and humidity levels up to 95% (non-condensing). Its parity-checked DRAM prevents data corruption from electrical interference, while a high MTBF of over 100,000 hours ensures minimal unplanned downtime, a critical factor for industries like manufacturing and energy where downtime equals significant losses.

Flexible Connectivity for Multitask Operations: The Motorola MVME-147-023 is equipped with a diverse set of interfaces—including two RS-232 serial ports for connecting to legacy sensors or HMIs, a parallel port for printers/plotters, and a SCSI-2 interface for high-speed external storage. This connectivity allows it to handle multiple tasks simultaneously, such as real-time data logging to SCSI drives, serial communication with field devices, and parallel data output for reporting. For industrial users, this flexibility eliminates the need for additional interface modules, simplifying system design and reducing integration costs.

Typical Application Scenarios

The Motorola MVME-147-023 is particularly well-suited for legacy industrial control systems in industries where equipment longevity and operational stability are paramount, such as manufacturing, oil and gas, and power generation. In discrete manufacturing (e.g., automotive component production), it serves as the CPU for VMEbus-based machine control systems, processing real-time signals from proximity sensors and encoders to regulate conveyor speeds, robotic arm movements, and assembly line sequencing. Its compatibility with legacy RS-232-based HMIs ensures that plant operators can continue using familiar control interfaces, avoiding the learning curve and costs of upgrading to new HMIs.

In the oil and gas sector, the Motorola MVME-147-023 is deployed in on-site control cabinets for upstream production facilities (e.g., wellhead monitoring). Its rugged environmental design allows it to operate reliably in outdoor or semi-enclosed spaces, where temperature fluctuations and dust are common. It collects data from pressure transducers and flow meters via serial ports, processes the data to detect anomalies (e.g., sudden pressure drops), and sends alerts to central control rooms—helping prevent equipment damage and ensure compliance with safety standards.

For power generation plants (e.g., coal-fired or hydroelectric), the Motorola MVME-147-023 is used in auxiliary control systems, such as boiler feedwater regulation or turbine lubrication control. Its high MTBF ensures continuous operation, even in 24/7 power generation environments, while its SCSI interface enables long-term data logging of operational parameters (e.g., temperature, pressure) for maintenance planning and regulatory reporting. For plant managers, the Motorola MVME-147-023 provides a cost-effective way to maintain reliable control of auxiliary systems without replacing entire legacy infrastructure.

Related Model Recommendations

Motorola MVME-147-022: A sibling model in the MVME-147 series, with the same 68040 processor but 2 MB DRAM (expandable to 8 MB) instead of 4 MB. It is a lower-memory alternative to the Motorola MVME-147-023 for less data-intensive applications, such as basic machine control.

Motorola MVME-162-001: An upgrade model from the MVME-147 series, featuring a faster 68060 processor (66 MHz) and enhanced I/O (including Ethernet). It is compatible with Motorola MVME-147-023-based systems and serves as a performance upgrade for users needing higher processing speed.

Motorola MVME-177-001: A complementary analog I/O module designed to work with the Motorola MVME-147-023. It adds 8-channel analog input (for voltage/current signals) and 4-channel analog output, expanding the MVME-147-023’s ability to interface with analog sensors/actuators.

Motorola MVME-187-002: A digital I/O module that pairs with the Motorola MVME-147-023 to provide 32-channel digital input and 32-channel digital output. It is ideal for users needing to connect the MVME-147-023 to discrete devices like limit switches or solenoids.

Motorola MVME-230-001: A communication interface module that adds Ethernet capability to the Motorola MVME-147-023, enabling integration with modern Ethernet-based industrial networks (e.g., Modbus TCP). It solves the MVME-147-023’s lack of native Ethernet, facilitating connectivity to upper-level SCADA systems.

Motorola MVME-147-024: A higher-memory variant of the Motorola MVME-147-023, with 8 MB DRAM (expandable to 32 MB). It is suitable for data-intensive applications like real-time process monitoring with large datasets.

Motorola MVME-147-023

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-147-023, ensure the VMEbus chassis meets the product’s physical and electrical requirements—verify the chassis supports 6U boards and provides ±5V, ±12V power (check voltage stability with a multimeter to avoid damage). Gather required tools: anti-static wristband (critical to prevent electrostatic discharge damage to the board’s components), Phillips screwdriver (for securing the board to the chassis), and a torque wrench (to ensure screws are tightened to 0.5 N·m, avoiding over-tightening). Clean the chassis’ backplane connector to remove dust or debris, and confirm the chassis is powered off before inserting the MVME-147-023—align the board with the chassis’ guide rails, slide it gently into the backplane, and secure it with screws.

Maintenance suggestions: For daily maintenance of the Motorola MVME-147-023, inspect the board monthly for physical damage (e.g., bent pins on connectors) and clean the chassis’ ventilation vents to prevent overheating (use compressed air with low pressure to avoid dust buildup on the board). If the board fails to boot, first check the power supply (ensure ±5V, ±12V are within 5% tolerance) and re-seat the board in the backplane to fix loose connections. For memory-related errors, replace the DRAM modules with compatible ones (confirm part numbers with the product manual). Spare parts like EPROM chips or serial port connectors should be stored in anti-static bags in a dry environment (20°C to 25°C, 30% to 50% humidity) to maintain functionality. Avoid exposing the MVME-147-023 to extreme temperatures or moisture during maintenance, as this can degrade component performance over time.

Service and Guarantee Commitment

The Motorola MVME-147-023 is backed by a comprehensive quality assurance program, with a 12-month warranty from the date of purchase (extendable to 24 months via optional service contracts). The warranty covers defects in materials and workmanship, including failures of the 68040 processor, memory modules, and I/O interfaces—if a defect is found, we provide free repair or replacement (whichever is more efficient) to minimize downtime for your operations.

Our after-sales support team offers technical assistance 24/7 via email and online portals—engineers with specialized expertise in Motorola MVME series products can help with installation troubleshooting, software configuration (e.g., OS setup for VxWorks), and compatibility issues with other industrial equipment. For legacy users, we maintain a stock of critical spare parts (e.g., DRAM, EPROM, SCSI connectors) to ensure fast replacement, even for long-discontinued models like the Motorola MVME-147-023. We also offer optional on-site service for commissioning and maintenance, where our technicians visit your facility to install, test, or repair the MVME-147-023, ensuring it integrates seamlessly with your existing system. Our commitment to the Motorola MVME-147-023 extends beyond the sale—we strive to support your industrial operations with reliable, timely service to maximize the product’s lifecycle value.