Description

Detailed Parameter Table

| Parameter name | Parameter value |

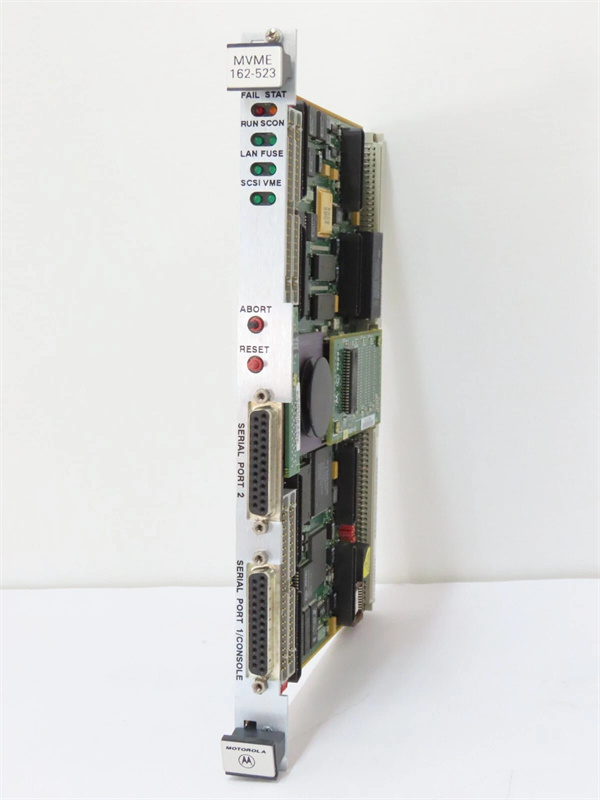

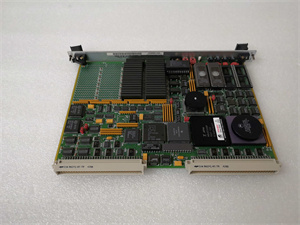

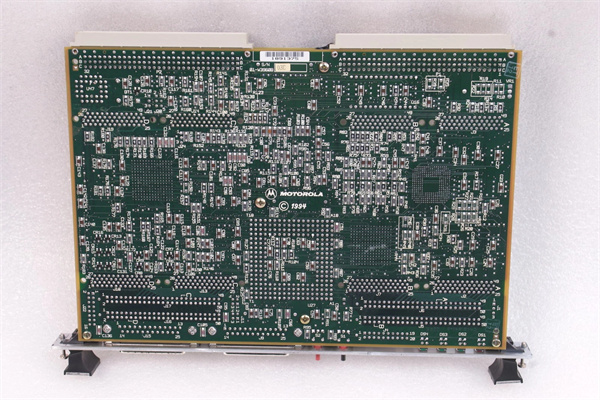

| Product model | Motorola MVME-162-523 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | High-Performance Industrial VMEbus Single-Board Computer (SBC) |

| Processor | Motorola PowerPC 750FX RISC processor, 800 MHz (32-bit data/address bus, with 256 KB L2 cache) |

| Memory | 512 MB DDR SDRAM (expandable to 1 GB via DIMM slot); 16 MB Flash ROM (boot/OS storage, with write protection) |

| Communication Interfaces | 2x 10/100/1000 Base-T Gigabit Ethernet (RJ45, TCP/IP/UDP/VLAN); 2x RS-232/422/485 serial ports (DB-9, configurable); 1x 4-lane Serial RapidIO (3.125 Gbps/lane) |

| Storage Interfaces | Integrated SATA II controller (supports 2.5″ HDD/SSD); 1x CompactFlash Slot (Type I/II, up to 128 GB); 1x USB 2.0 port (for external storage/debugging) |

| Expansion Slots | 2x 32-bit/66 MHz PMC (PCI Mezzanine Card) slots (full-height, compatible with analog I/O, motion control cards); 1x VMEbus P2 expansion connector |

| Environmental Requirements | Operating temp: -40°C to 70°C (-40°F to 158°F); Storage temp: -55°C to 85°C (-67°F to 185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 100 g (peak, 1 ms) |

| Physical Size | 6U VMEbus form factor: 233.35 mm × 160.02 mm (9.19 in × 6.30 in); Weight: 580 g (1.28 lbs) |

| Power Consumption | Typical: 28 W (25°C, full load); Maximum: 35 W |

| Operating System Support | VxWorks 6.9+, QNX Neutrino 6.6+, Linux for PowerPC (kernel 4.1+); Motorola RTOS for legacy systems |

| Diagnostic Features | Advanced Built-in Self-Test (BIST) for processor/memory/network/storage; Redundant watchdog timers (1–120s, configurable); LED indicators (power, Ethernet, fault, PMC status); Remote health monitoring via Ethernet |

Motorola MVME-162-523

Product Introduction

The Motorola MVME-162-523 is a flagship high-performance industrial VMEbus Single-Board Computer (SBC) from Motorola (now integrated into Emerson’s portfolio), leading the MVME-162 series—renowned for extreme processing power, ruggedness, and expandability for mission-critical automation. As a top-tier model in the series, the Motorola MVME-162-523 is engineered to tackle data-intensive, low-latency tasks such as real-time multi-axis motion control, high-frequency sensor data acquisition (1000+ samples/second), and complex industrial analytics—outperforming mid-tier SBCs like the Motorola MVME-167-04B in demanding scenarios.

In automation systems, the Motorola MVME-162-523 acts as a “supervisory processing hub”: it aggregates data from dozens of peripheral modules (e.g., Motorola MVME-761-001 analog I/O for pressure/temperature, Motorola MVME-717 digital input for sensor status), processes it using its 800 MHz PowerPC 750FX processor, and executes synchronized control commands for high-precision actuators (e.g., robotic arms, servo motors). Its Gigabit Ethernet and Serial RapidIO interfaces enable ultra-fast data transmission to cloud SCADA systems or local VMEbus modules, while dual PMC slots support customization for specialized tasks (e.g., motion control, vision processing). This makes the Motorola MVME-162-523 indispensable for industries like aerospace, semiconductor manufacturing, and power grid management—where reliability, speed, and harsh environment tolerance are non-negotiable.

Core Advantages and Technical Highlights

Extreme Processing Power for Demanding Tasks: The Motorola MVME-162-523 features an 800 MHz PowerPC 750FX processor with 256 KB L2 cache and 512 MB DDR SDRAM (expandable to 1 GB)—delivering 3x the computing performance of mid-tier models like the Motorola MVME-167-04B. This enables it to handle 1000+ concurrent sensor data streams (e.g., in aerospace component vibration testing) and execute complex algorithms (e.g., adaptive PID control for semiconductor wafer positioning) with latency <5 ms. Unlike lower-power SBCs, the Motorola MVME-162-523 eliminates bottlenecks in high-speed automation, such as a 6-axis robotic assembly line where 100+ data points per second must be processed to maintain sub-millimeter precision.

Dual High-Speed Connectivity for Seamless Integration: A defining feature of the Motorola MVME-162-523 is its 2x Gigabit Ethernet ports and 4-lane Serial RapidIO (3.125 Gbps/lane). The Gigabit Ethernet supports VLAN and QoS (Quality of Service) for prioritized data transfer—critical for sending time-sensitive control commands to cloud platforms (e.g., power grid load balancing data). Serial RapidIO enables low-latency (sub-1 ms) communication with other VMEbus modules (e.g., Motorola MVME-910-3 Ethernet gateways), ensuring synchronized operation of distributed systems. This dual-connectivity design allows the Motorola MVME-162-523 to bridge modern IP-based networks and legacy VMEbus ecosystems, reducing retrofitting costs for factories upgrading from older infrastructure.

Ultra-Rugged Design for Harsh Environments: Built to military-grade durability standards, the Motorola MVME-162-523 operates in temperatures ranging from -40°C to 70°C—surviving extreme cold (e.g., arctic oil pipelines) and heat (e.g., steel mill control cabinets). It resists 2.0 g rms vibration (10–2000 Hz) and 100 g peak shock (1 ms), protecting internal components from mechanical stress in mobile applications (e.g., train traction control systems). The SBC uses industrial-grade components: wide-temperature DDR SDRAM (-40°C to 85°C), gold-plated VMEbus connectors (corrosion-resistant), and conformal coating (optional) for moisture/dust protection. With a mean time between failures (MTBF) exceeding 300,000 hours, the Motorola MVME-162-523 ensures 24/7 operation in environments where downtime costs exceed $10,000 per minute.

Dual PMC Slots for Maximum Expandability: The Motorola MVME-162-523 includes 2x 32-bit/66 MHz PMC slots (vs. 1 slot in the Motorola MVME-167-04B), enabling simultaneous integration of specialized modules. For example, adding a PMC motion control card (e.g., Motorola MVME-253) allows control of 8 servo axes for robotic welding, while a PMC vision processing card enables real-time defect detection in semiconductor wafers. This expandability eliminates the need for multiple SBCs, reducing chassis space and system complexity. Unlike fixed-function controllers, the Motorola MVME-162-523 adapts to evolving application needs—e.g., upgrading from basic control to AI-powered analytics by adding a PMC GPU card.

Typical Application Scenarios

In aerospace component testing facilities, the Motorola MVME-162-523 is the core of vibration and thermal cycling test systems. It connects to 200+ accelerometers (via Motorola MVME-761-001 analog I/O modules) to collect 1000 samples/second per sensor, processing data to generate real-time vibration profiles (e.g., simulating aircraft takeoff forces). Its 1 GB DDR SDRAM logs 1 week of test data to a SATA SSD, while Gigabit Ethernet sends results to a central database for certification. The Motorola MVME-162-523’s -40°C to 70°C operating range handles the test chamber’s extreme temperature cycles, and its shock resistance (100 g) protects against accidental equipment drops—critical for validating aircraft engine components.

For semiconductor wafer fabrication, the Motorola MVME-162-523 controls 8-axis robotic wafer handlers in cleanrooms. It uses a PMC motion control card to synchronize the robot’s arm movements (sub-millimeter precision) and a second PMC vision card to align wafers with lithography tools. The SBC processes 500+ data points/second (e.g., wafer position, vacuum pressure) via Serial RapidIO, executing adaptive PID loops to correct positioning errors in <5 ms. Its Gigabit Ethernet port transmits production data to a factory MES (Manufacturing Execution System), while the CompactFlash slot stores backup process recipes. The Motorola MVME-162-523’s low power consumption (28 W typical) and fanless design (optional) comply with cleanroom air quality standards, avoiding particle contamination.

In high-voltage power grid control centers, the Motorola MVME-162-523 manages 50+ substation transformers and 100+ current sensors. It collects analog data (via Motorola MVME-761-001 modules) such as transformer temperature and line current, running real-time analytics to detect faults (e.g., short circuits) and trigger circuit breaker commands via Motorola MVME-712-11 output modules. Its redundant Gigabit Ethernet ports ensure 99.999% connectivity to the grid’s SCADA system, while the 16 MB Flash ROM (write-protected) prevents firmware tampering. The Motorola MVME-162-523’s -40°C operating range withstands cold substation enclosures, ensuring uninterrupted grid stability during winter storms.

Motorola MVME-162-523

Related Model Recommendations

Motorola MVME-162-524: A redundant variant of the Motorola MVME-162-523 with dual processors (800 MHz PowerPC 750FX) and mirrored memory. Ideal for safety-critical applications (e.g., nuclear power control) requiring fault tolerance.

Motorola MVME-167-04B: A mid-tier alternative to the Motorola MVME-162-523 with a 166 MHz PowerPC 603e. Suitable for less demanding tasks (e.g., water treatment control) where high processing power is unnecessary.

Motorola MVME-253: A PMC motion control card for the Motorola MVME-162-523. It supports 8 servo axes, enabling precise robotic control in manufacturing or testing applications.

Motorola MVME-761-001: An analog I/O module fully compatible with the Motorola MVME-162-523. It provides 16 analog inputs/8 outputs for monitoring temperature, pressure, or voltage in industrial processes.

Motorola MVME-051: A high-power industrial supply for the Motorola MVME-162-523. It delivers stable ±5V/±12V/±15V output (85–264 VAC input) to power the SBC and dual PMC cards, handling the 35 W maximum load.

Motorola MVME-910-3: An Ethernet gateway module that expands the Motorola MVME-162-523’s network redundancy. It adds a third Gigabit Ethernet port for backup SCADA connectivity, ensuring no data loss during primary network outages.

Motorola MVME-177-001: A high-precision analog I/O module paired with the Motorola MVME-162-523 for aerospace testing. It offers 16-bit resolution (vs. 12-bit in MVME-761-001) for accurate sensor data acquisition.

Motorola MVME-712-11: A digital output module for the Motorola MVME-162-523. It provides 16 high-current (2 A) channels to control actuators (e.g., circuit breakers, valves) in power grid or manufacturing applications.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-162-523, verify the VMEbus chassis supports 6U modules and provides stable ±5V/±12V/±15V power (use a multimeter to confirm voltage tolerance within ±3% for high-performance operation). Gather tools: anti-static wristband (essential for protecting the 800 MHz processor and DDR SDRAM), torque screwdriver (0.5 N·m for chassis mounting), Gigabit Ethernet cable tester, and a laptop (for OS configuration via USB 2.0). If installing PMC cards, ensure they are full-height compatible—align the card with the SBC’s slot guides, press gently until seated, and secure with locking screws. Power off the chassis, clean the VME backplane connector with compressed air (20 PSI max) to remove dust, then slide the Motorola MVME-162-523 into the backplane until fully seated (ensure no pins are bent).

Maintenance suggestions: For daily upkeep, inspect the Motorola MVME-162-523’s LEDs—steady green power, blinking Gigabit Ethernet, and solid PMC status LEDs indicate normal operation. A red fault LED signals issues (run advanced BIST via the OS to diagnose memory/network/storage faults). Clean the SBC’s air vents (if fan-cooled) monthly with compressed air (30 PSI max) to prevent overheating; for fanless variants, wipe the chassis with a dry cloth. Every 6 months, back up the SATA SSD/CompactFlash data to a secure server and update the Flash ROM firmware (via Emerson’s online portal) to patch security vulnerabilities. If the Motorola MVME-162-523 experiences latency spikes, check for PMC card conflicts (disable non-essential cards temporarily) and verify Serial RapidIO cable integrity. Store spare units in anti-static bags in a climate-controlled environment (-10°C–30°C, 30%–60% humidity) to preserve component life.

Service and Guarantee Commitment

The Motorola MVME-162-523 is backed by a 36-month factory warranty from Emerson, covering defects in materials and workmanship (e.g., processor failures, Gigabit Ethernet port malfunctions, PMC slot issues). If a defect is identified during the warranty period, Emerson provides free next-day replacement for in-stock units—critical for mission-critical systems where downtime is catastrophic. For extended support, customers can purchase premium service contracts (up to 60 months) that include 24/7 dedicated technical support, quarterly on-site system health checks, and priority access to firmware updates.

Emerson maintains a global stock of critical components for the Motorola MVME-162-523 (e.g., PowerPC 750FX processors, DDR SDRAM modules) to support legacy users until 2040. Technical support engineers specialize in high-performance VMEbus systems, offering remote troubleshooting (via Ethernet) and on-site repair for complex issues (e.g., PMC card integration). This commitment ensures the Motorola MVME-162-523 delivers long-term value, whether deployed in new aerospace test systems or upgrading legacy power grid controllers.