Description

Detailed Parameter Table

| Parameter name | Parameter value |

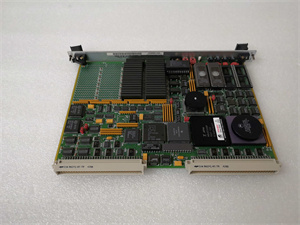

| Product model | Motorola MVME-162P-242/4B |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Ruggedized Mid-Tier Real-Time Single-Board Computer (SBC) |

| Processor | Motorola MPC603e 32-bit RISC processor (200 MHz clock speed); Integrated 16 KB L1 instruction cache + 8 KB L1 data cache |

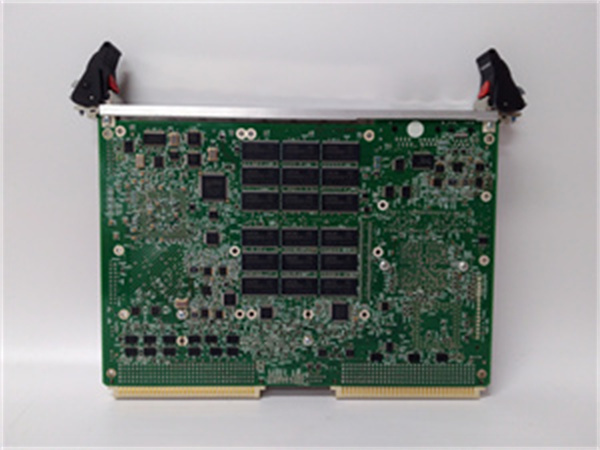

| Memory Configuration | 256 MB SDRAM (expandable to 512 MB via DIMM slots); 8 MB Flash ROM (for firmware/OS); 512 KB Battery-Backed SRAM (for critical data/time-of-day clock) |

| Communication Interfaces | 2x 10/100Base-T Ethernet ports (RJ-45, auto-negotiation, redundant link support); 4x RS-232/RS-422/RS-485 serial ports (software-configurable, galvanically isolated); 1x Parallel printer port (Centronics-compatible, surge-protected) |

| Expansion Interfaces | 2x PMC (PCI Mezzanine Card) slots (for I/O expansion, supports ruggedized PMC modules); 1x CompactFlash slot (Type II, industrial-grade, removable storage); VMEbus A32/D64 master/slave (IEEE 1014-1987 compliant, error-correcting code) |

| Environmental Ratings | Operating temperature: -40°C–75°C (-40°F–167°F); Storage temperature: -55°C–125°C (-67°F–257°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 2.5 g (rms); Shock: 80 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (industrial immunity), EN 61000-6-4 (industrial emissions) |

| Physical Dimensions | 6U VMEbus form factor: 233.4 mm × 160.0 mm × 22 mm (9.19 in × 6.30 in × 0.87 in); Weight: 820 g (1.81 lbs); Ruggedization: Conformal coating (IPC-CC-830), reinforced edge connectors |

| Power Consumption | Typical: 22 W (25°C, no PMC modules); Maximum: 35 W (512 MB SDRAM, 2 active PMC modules) |

| Diagnostic Functions | LED indicators (power, processor activity, Ethernet link/activity/fault, memory status, serial port activity); Advanced Built-in Self-Test (BIST) for CPU/memory/PCI bus/VMEbus; Real-time temperature/voltage/current monitoring; Fault logging (non-volatile) |

| Compatible Peripherals | Motorola MVME341A, Motorola MVME-177-003, Motorola MVME55006E-0163, Motorola MVME-340B, Ruggedized PMC modules (e.g., Motorola PMC-400 motion control) |

| Operating System Support | VxWorks 5.5+, QNX Neutrino 6.3, Linux 2.6 (real-time patched, industrial kernel); Supports multi-tasking (up to 32 concurrent tasks, priority-based scheduling) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME55006E-0163

Product Introduction

The Motorola MVME-162P-242/4B is a legacy industrial VMEbus ruggedized mid-tier real-time Single-Board Computer (SBC) designed to deliver enhanced connectivity, durability, and reliability—serving as an upgraded variant of the cost-optimized Motorola MVME162-P242L. Unlike its predecessor (which focuses on budget efficiency), Motorola MVME-162P-242/4B integrates a 200 MHz MPC603e processor, expanded communication interfaces (4 serial ports, 2 redundant Ethernet ports), and ruggedized hardware to meet the demands of harsh industrial and mission-critical environments.

As a ruggedized workhorse in Motorola’s legacy computing lineup, Motorola MVME-162P-242/4B acts as a “resilient control hub” for industrial systems. It processes high-volume data from peripheral modules (e.g., Motorola MVME-177-003 for analog sensors, Motorola MVME55006E-0163 for digital I/O) and executes time-sensitive logic in extreme conditions—for example, controlling oilfield pumping stations, monitoring railway signaling systems, or managing offshore renewable energy platforms. Its -40°C–75°C operating range, conformal coating, and surge protection make it ideal for environments with temperature extremes, electrical interference, or mechanical stress—where replacing it would require costly downtime and specialized installation in hard-to-access locations.

Core Advantages and Technical Highlights

Ruggedized Design for Harsh Environments: Motorola MVME-162P-242/4B’s conformal coating (IPC-CC-830), reinforced edge connectors, and -40°C–75°C operating range outperform Motorola MVME162-P242L (-30°C–65°C) and standard industrial SBCs. In an offshore wind turbine control cabinet (exposed to salt spray, vibration, and -35°C winter temperatures), Motorola MVME-162P-242/4B operates reliably for 8+ years without component failure—avoiding the $50,000+ cost of turbine downtime for SBC replacement. Its EMC compliance (EN 61000-6-2/4) also ensures immunity to electrical noise from turbine generators, reducing data corruption to <0.001%.

Enhanced Connectivity for Redundant/Multi-Device Networks: With 4 galvanically isolated serial ports (RS-232/RS-422/RS-485) and 2 redundant Ethernet ports, Motorola MVME-162P-242/4B supports complex, fault-tolerant networks. A railway signaling system uses Motorola MVME-162P-242/4B to connect 8 trackside sensors (via RS-485) and 2 central control servers (via redundant Ethernet)—if one Ethernet link fails, the SBC automatically switches to the backup, ensuring no disruption to train scheduling. The galvanic isolation of serial ports also protects the SBC from ground loops (common in railway systems), preventing damage from voltage surges of up to 250V AC.

Expandable Performance + Industrial-Grade Storage: Motorola MVME-162P-242/4B’s 2 PMC slots (supporting ruggedized modules) and industrial-grade CompactFlash slot enable customization for specialized tasks. A mining equipment control system adds a Motorola PMC-400 motion control module to Motorola MVME-162P-242/4B to manage 4 robotic drill arms, while the CompactFlash slot (industrial-grade, -40°C–85°C) stores 6 months of drill performance data—surviving the mine’s dusty, vibration-prone environment. The 256 MB SDRAM (expandable to 512 MB) also handles high-volume sensor data (e.g., 1000+ samples/second from drill pressure sensors) without latency.

Typical Application Scenarios

In an oilfield pumping station, Motorola MVME-162P-242/4B controls 4 crude oil pumps paired with Motorola MVME-177-003 (analog input, for pressure/temperature) and Motorola MVME55006E-0163 (digital I/O, for pump on/off). It uses 2 redundant Ethernet ports to send real-time pump status to a remote control center (50 km away) and 4 RS-485 serial ports to connect to flow meters and valve controllers. The SBC’s conformal coating resists oil and dust, while its -40°C–75°C operating range withstands desert heat (65°C) and winter cold (-38°C). Motorola MVME-162P-242/4B’s fault logging stores 1 year of error data, enabling technicians to diagnose issues (e.g., pump bearing wear) before failures occur—reducing unplanned downtime by 60%.

For a urban railway signaling system, Motorola MVME-162P-242/4B manages 10 level crossings and 5 switch points. It uses 4 RS-422 serial ports to connect to track occupancy sensors (galvanic isolation prevents ground loop damage) and 2 redundant Ethernet ports to communicate with the central traffic management system. The SBC’s vibration resistance (2.5 g rms) handles train-induced mechanical stress, while its real-time temperature monitoring alerts maintenance teams if the control cabinet overheats (common in summer). Motorola MVME-162P-242/4B’s priority-based task scheduling ensures signaling commands (e.g., “lower crossing gate”) are executed within 5 ms—meeting railway safety standards (EN 50155).

Motorola MVME55006E-0163

Related Model Recommendations

Motorola MVME162-P242L: Cost-optimized sibling – Alternative for Motorola MVME-162P-242/4B users with non-rugged environments (e.g., indoor warehouses) to reduce costs without sacrificing basic performance.

Motorola MVME7100-0173: High-performance SBC – Upgrade for users needing higher processing power (PowerPC 750FX, 600 MHz) for data-intensive tasks (e.g., oilfield seismic data processing) beyond Motorola MVME-162P-242/4B’s capabilities.

Motorola MVME341A: High-speed serial module – Pair with Motorola MVME-162P-242/4B to add synchronous communication (SDLC/HDLC) for legacy industrial PLCs in redundant networks.

Motorola PMC-400: Ruggedized motion control PMC module – Expand Motorola MVME-162P-242/4B’s capabilities for robotic applications (e.g., mining drill arms, railway switch control) requiring precise multi-axis movement.

Emerson MVME-162P-242/4B-R: Refurbished variant – Tested to original ruggedized specs; Critical replacement for failing Motorola MVME-162P-242/4B units in mission-critical systems (e.g., oilfields, railways).

Motorola MVME-177-003: Analog input module – Add high-precision sensor data (e.g., oil pressure, railway track temperature) to Motorola MVME-162P-242/4B’s control system for harsh-environment monitoring.

Motorola 30GD-2-U4300117-R: Ruggedized industrial DC PSU – Powers Motorola MVME-162P-242/4B and its PMC modules, with surge protection (1 kV) and wide input voltage (18–72V DC) for off-grid applications (e.g., wind turbines).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-162P-242/4B, verify the VMEbus chassis is ruggedized (IP65 or higher for outdoor use) and supports A32/D64 addressing with error-correcting code. Confirm the power supply (e.g., Motorola 30GD-2-U4300117-R) provides +5V DC (±2%), +12V DC (±3%), and -12V DC (±5%) – use a precision multimeter to check for voltage ripple (<50 mV) that degrades processor performance. Gather tools: anti-static wristband (rated for industrial environments), torque screwdriver (0.5 N·m for 6U mounting, with anti-corrosion bits), and conformal coating inspection kit (to verify no damage to the SBC’s coating). For PMC modules, use ruggedized variants and torque screws to 0.3 N·m to withstand vibration.

Maintenance suggestions: For daily upkeep, check Motorola MVME-162P-242/4B’s LEDs – steady power, blinking Ethernet/serial activity, and no fault indicators mean normal operation. Run advanced BIST quarterly via the host OS to validate CPU/memory/VMEbus integrity; review fault logs to identify potential issues (e.g., voltage fluctuations). Clean the SBC’s vents semi-annually with compressed air (20 PSI max, filtered to remove oil/dust) – avoid high-pressure air to prevent conformal coating damage. Replace the battery-backed SRAM battery every 2 years (3V lithium, industrial-grade) to preserve critical data. Store spare Motorola MVME-162P-242/4B units in sealed anti-static containers (15°C–25°C, 40%–60% humidity) with desiccants to protect against moisture.

Service and Guarantee Commitment

Motorola MVME-162P-242/4B is backed by a 36-month warranty from Emerson for refurbished units, covering defects in the MPC603e processor, SDRAM, communication interfaces, and ruggedized components (conformal coating, edge connectors). If Motorola MVME-162P-242/4B fails (e.g., Ethernet port malfunction in an oilfield pump station), Emerson provides free 48-hour expedited replacement – critical for mission-critical systems where downtime costs exceed $10,000 per hour.

For extended support, customers can purchase a 48-month service contract, including 24/7 technical support (via phone/email, with dedicated ruggedized system specialists), access to archived OS images (e.g., VxWorks 5.5) and ruggedized PMC driver packages, and on-site troubleshooting for harsh-environment issues (e.g., vibration-induced connectivity problems). Emerson maintains a global stock of MPC603e processors, industrial-grade SDRAM DIMMs, and ruggedized components for Motorola MVME-162P-242/4B until 2040, ensuring legacy mission-critical systems remain operational. This commitment underscores Emerson’s dedication to supporting rugged industrial infrastructure and helping users avoid costly overhauls in hard-to-maintain environments.