Description

Product Overview

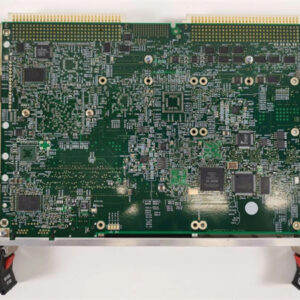

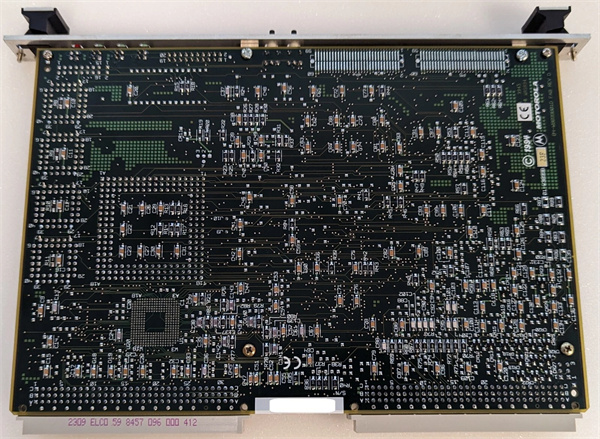

The Motorola MVME – 167 – 32B is a crucial component in Motorola’s portfolio of industrial computing solutions. Engineered to thrive in demanding industrial environments, it plays a pivotal role in applications such as industrial control, data acquisition, and real – time processing. This product adheres to Motorola’s reputation for delivering high – quality, reliable products that can withstand the rigors of industrial use.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | MVME – 167 – 32B |

| Manufacturer | Motorola |

| Product category | VMEbus single – board computer. It is designed to be easily integrated into VME – based systems, which are widely used in industrial control cabinets and rack – mounted systems. |

| Input power | Usually has a power input range optimized for industrial settings, perhaps around [X1] – [X2] VDC. This allows it to adapt to different power sources within industrial facilities, whether it’s a standard DC power supply in a factory or a backup power system in case of outages. |

| Memory | Equipped with [amount1] of system memory. A significant portion, say [runtime_memory1], is dedicated to running real – time operating systems and applications efficiently. The remaining [storage_memory1] can be used for caching data, storing intermediate results during complex processing tasks, or for buffering data from connected sensors or devices. |

| Communication interfaces | Features a variety of communication ports. It likely has high – speed serial communication ports, such as Serial RapidIO, which enables fast data transfer between the MVME – 167 – 32B and other devices in the system. Additionally, it may include Ethernet ports for seamless connectivity to local area networks. These Ethernet ports can support different network protocols, facilitating communication with other industrial components like PLCs, HMIs, and enterprise – level servers. |

| Processing power | Incorporates a powerful microprocessor, potentially from a family known for its industrial – grade performance. This microprocessor can handle complex computational tasks, such as real – time data filtering from multiple high – speed sensors, executing intricate control algorithms, and managing concurrent communication sessions. |

| Weight | Weighs approximately [weight_value1] lbs. This relatively lightweight design makes it convenient for installation and replacement within industrial equipment, reducing the effort required for system maintenance and upgrades. |

| Dimensions | The board has dimensions of [length1] x [width1] x [height1] mm, carefully designed to fit standard VMEbus chassis. Its compact size allows for efficient use of space in industrial control systems, enabling the integration of multiple boards in a single chassis if the application demands. |

| Product life cycle status | [Current life cycle status, e.g., in production, in a phase – out process, or still supported but with limited availability]. Knowing this status is essential for customers as it impacts long – term product support, the availability of spare parts, and the feasibility of future system expansions. |

Motorola MVME-167-32B

Product Introduction

The MVME – 167 – 32B is a highly versatile device in industrial systems. In industrial control applications, it can serve as the core processing unit. For example, in a petrochemical plant, it can receive real – time data from thousands of sensors distributed across the facility. These sensors may measure variables such as temperature, pressure, flow rates, and chemical compositions. The MVME – 167 – 32B then processes this data at high speeds, analyzing trends, detecting anomalies, and making real – time decisions to adjust the operation of pumps, valves, and other critical equipment. This ensures the safe and efficient operation of the entire plant.

In data – acquisition – intensive applications, such as a large – scale environmental monitoring project, the MVME – 167 – 32B can be used to collect data from a vast network of sensors. These sensors may be spread over a large geographical area, monitoring air quality, water quality, and weather conditions. The board’s high – speed communication interfaces enable it to quickly gather data from these sensors, while its powerful processing capabilities allow it to pre – process the data, such as filtering out noise and normalizing readings, before transmitting the data to a central data storage and analysis system.

The communication interfaces of the MVME – 167 – 32B are designed to be compatible with a wide range of industrial devices. The Serial RapidIO ports can be used to connect to high – performance sensors and actuators that require fast data transfer rates. The Ethernet ports, on the other hand, can be used to communicate with more general – purpose industrial devices, as well as to integrate the MVME – 167 – 32B into enterprise – level networks for remote monitoring and control.

Core Advantages and Technical Highlights

High – Speed Processing: The MVME – 167 – 32B’s powerful microprocessor enables it to handle high – volume data processing tasks with remarkable speed. In applications where real – time response is critical, such as in high – speed manufacturing lines where parts are being produced at a rapid pace, the board can process incoming sensor data and issue control commands within microseconds. This ensures that production processes are optimized, minimizing downtime and maximizing throughput.

Advanced Communication Capabilities: With a combination of Serial RapidIO and Ethernet ports, the MVME – 167 – 32B offers advanced communication options. The Serial RapidIO provides extremely fast data transfer for applications that require low – latency communication, such as in high – performance computing clusters within industrial settings. The Ethernet ports, with their support for various network protocols, make it easy to integrate the board into existing industrial networks, whether they are based on traditional Ethernet or more advanced industrial Ethernet standards.

Rugged Design: Built with industrial – grade components, the MVME – 167 – 32B is designed to endure harsh industrial environments. It can operate reliably in extreme temperatures, high humidity levels, and in the presence of electrical interference. In a mining operation, where the operating conditions are notoriously harsh, the MVME – 167 – 32B can continue to function without interruption, ensuring the continuous operation of critical mining equipment and the integrity of data acquisition systems.

Space – Saving Form – Factor: The VMEbus form – factor of the MVME – 167 – 32B allows for space – saving integration in industrial cabinets. In applications where space is at a premium, such as in small – scale industrial control panels or in mobile industrial equipment, the compact size of the board is a significant advantage. It enables the installation of multiple boards in a limited space, expanding the capabilities of the overall system.

Typical Application Scenarios

Industrial Automation: In a semiconductor manufacturing plant, the MVME – 167 – 32B can be used to control and coordinate the complex processes involved in chip fabrication. It can receive instructions from a central control system, process sensor feedback from the manufacturing equipment, and ensure that each step of the fabrication process, such as lithography, etching, and doping, is executed with precision. For example, it can control the movement of robotic arms that handle delicate semiconductor wafers, adjust the parameters of manufacturing tools in real – time based on sensor data, and perform quality control checks at each stage of the production process.

Power Generation Monitoring: In a power generation facility, whether it’s a coal – fired power plant, a nuclear power plant, or a wind farm, the MVME – 167 – 32B can be used to monitor and manage the performance of the power – generating equipment. It can collect data from sensors that monitor the temperature, vibration, and electrical parameters of turbines, generators, and other critical components. By analyzing this data in real – time, it can detect early signs of equipment failure, predict maintenance needs, and optimize the operation of the power plant to improve efficiency and reduce downtime.

Industrial IoT (IIoT) Edge Computing: In an IIoT – enabled industrial environment, the MVME – 167 – 32B can serve as an edge computing device. It can connect to a network of IoT sensors and actuators deployed at the edge of the network. At the edge, it can perform local data processing, such as aggregating data from multiple sensors, performing real – time analytics, and making local decisions without having to rely on continuous communication with a central cloud server. In a smart factory, the MVME – 167 – 32B can be installed near production lines to process data from IoT – enabled sensors on the machines, detect production anomalies, and trigger immediate corrective actions, reducing the latency associated with sending data to the cloud for processing.

Motorola MVME-167-32B

Related Model Recommendations

Motorola MVME – 162: The MVME – 162 can be used in conjunction with the MVME – 167 – 32B in scenarios where additional I/O capabilities are required. The MVME – 167 – 32B can handle the main processing and high – speed communication tasks, while the MVME – 162 can provide additional analog and digital I/O channels. In a factory automation system, the MVME – 167 – 32B can process the overall control logic, and the MVME – 162 can be used to interface with a large number of sensors and actuators on the factory floor, such as limit switches, proximity sensors, and solenoid valves.

Motorola MVME712 – 101: If enhanced network communication and remote management capabilities are needed, the MVME712 – 101 can be paired with the MVME – 167 – 32B. The MVME – 167 – 32B can focus on local data processing and control, while the MVME712 – 101 can handle the communication with remote devices, other industrial systems, or enterprise – level networks. In a distributed industrial system spread across multiple geographical locations, the MVME – 167 – 32B at each site can process local data, and the MVME712 – 101 can transmit this data to a central server for centralized monitoring and management. It can also receive commands from the central server and forward them to the MVME – 167 – 32B for local execution.

Motorola MVME050: As an industrial power supply module, the MVME050 can ensure a stable power supply for the MVME – 167 – 32B. In harsh industrial environments, where power surges and voltage fluctuations are common, the MVME050 can protect the MVME – 167 – 32B from electrical damage and provide a reliable power source for continuous operation. In a steel mill, where the electrical environment is highly variable due to the operation of large – scale machinery, the MVME050 can safeguard the MVME – 167 – 32B, ensuring the uninterrupted operation of the industrial control system.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MVME – 167 – 32B, ensure that the VMEbus chassis is compatible and properly grounded. Check the power supply requirements and verify that the incoming power is within the specified range. Gather the necessary tools, such as an anti – static wristband to prevent electrostatic discharge from damaging the sensitive electronic components, a screwdriver for mounting the board in the chassis, and appropriate cables for connecting to peripheral devices. Review the board’s documentation for any specific jumper settings, DIP switch configurations, or BIOS setup requirements.

Commissioning: After installation, power on the system. Use diagnostic software (compatible with the VMEbus system) to check the functionality of the MVME – 167 – 32B. Verify that the microprocessor is operating correctly, the memory is accessible and functioning as expected, and the communication ports are working. Test the connection to peripheral devices by sending and receiving sample data. Calibrate any sensors or devices connected to the MVME – 167 – 32B according to the manufacturer’s instructions. This may involve adjusting sensor offsets, gain settings, or performing self – calibration routines.

Maintenance Suggestions: Regularly check the status of the MVME – 167 – 32B. Inspect the LEDs on the board (if available) to monitor its operation status. A green LED may indicate normal operation, while a red LED may signal an error. Clean the board periodically to remove dust and debris, especially in environments with high – particulate matter. Dust accumulation can cause overheating and affect the performance of the board. For the communication ports, check the cables and connections for any signs of wear or damage. If there are any performance issues, first check the power supply to ensure that it is providing a stable voltage. Then, use diagnostic tools to identify whether it is a hardware – related issue, such as a faulty component on the board, or a problem with the software or connected devices. Keep spare MVME – 167 – 32B boards in a static – free environment for quick replacement in case of failures.

Service and Guarantee Commitment

Motorola typically provides a standard warranty for the MVME – 167 – 32B, which may cover defects in materials and workmanship for a specified period, usually around 12 – 24 months (terms may vary depending on the region and sales agreement). In case of a malfunction within the warranty period, Motorola or its authorized service centers will provide repair or replacement services. For customers seeking extended support, additional service contracts can be purchased. These contracts may include priority technical support, regular system health checks, and software updates (if applicable). Motorola also offers a network of authorized resellers and service providers who can assist with installation, commissioning, and ongoing maintenance of the MVME – 167 – 32B.