Description

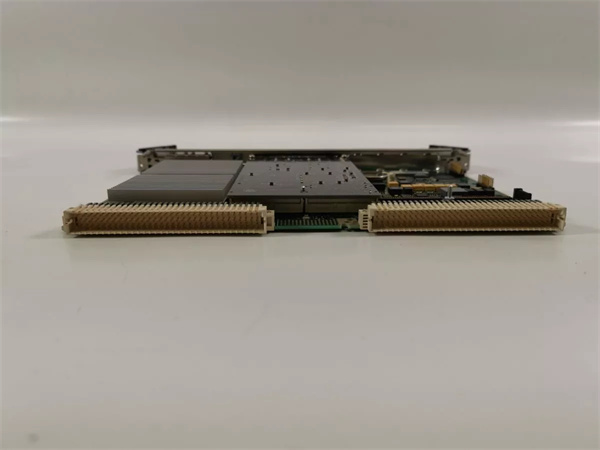

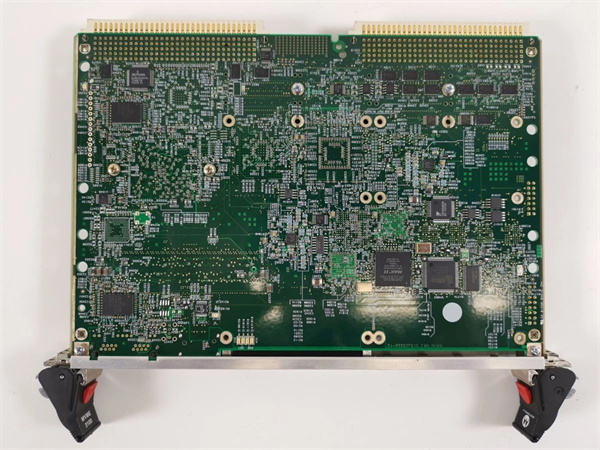

Motorola MVME3100 Product Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | MVME3100 |

| Manufacturer | Motorola |

| Product category | VMEbus single – board computer |

| Processor | Freescale MPC8548 PowerQUICC III running at 1 GHz |

| Memory | 512 MB DDR2 SDRAM (expandable up to 2 GB) |

| Storage interfaces | 1 x CompactFlash Type I/II slot, 1 x SATA interface |

| Communication interfaces | 4 x Gigabit Ethernet ports, 2 x RS – 232 serial ports, 1 x CAN bus interface |

| VMEbus interface | Complies with VME64x standard, supports 32 – bit/33 MHz and 64 – bit/66 MHz data transfer modes |

| Operating temperature range | 0°C – 55°C |

| Storage temperature range | – 40°C – 85°C |

| Dimensions | 160 mm x 233.35 mm (6U VME form factor) |

| Weight | Approximately 1.8 kg |

| Power supply requirements | +5 VDC, +12 VDC; typical power consumption 40 W |

| Expansion slots | 2 x PMC (PCI Mezzanine Card) expansion slots |

MVME3100

Product introduction

The Motorola MVME3100 is a cutting – edge VMEbus single – board computer designed by Motorola, a trusted leader in industrial computing solutions. As a part of Motorola’s high – performance product line, the MVME3100 is engineered to meet the complex demands of modern industrial automation, control, and data – intensive applications.

Powered by the Freescale MPC8548 PowerQUICC III processor running at 1 GHz, the MVME3100 offers exceptional computing power. With a standard 512 MB of DDR2 SDRAM, expandable up to 2 GB, it can handle resource – intensive tasks with ease. The module’s diverse set of interfaces, including multiple Ethernet ports, serial ports, and a CAN bus interface, enables seamless connectivity with a wide range of industrial devices. In an industrial automation system, the MVME3100 acts as a central processing unit, collecting data from various sensors, analyzing it in real – time, and sending out precise control signals to actuators. Its compliance with the VME64x standard ensures compatibility and easy integration into existing or new VME – based industrial setups, making it an essential component for efficient industrial operations.

Core advantages and technical highlights

High – performance processing

The MVME3100‘s 1 GHz Freescale MPC8548 PowerQUICC III processor provides remarkable processing capabilities. In data – driven industrial applications, such as real – time analytics in large – scale manufacturing plants, it can quickly process vast amounts of sensor data. The expandable memory up to 2 GB allows the module to handle increasingly complex algorithms and large – scale data processing tasks. Whether it’s running advanced control systems or managing big data analytics in industrial environments, the MVME3100 ensures smooth and efficient operation, reducing processing delays and enhancing overall system productivity.

Versatile connectivity

Featuring 4 Gigabit Ethernet ports, the MVME3100 enables high – speed data transfer, which is crucial for applications that require real – time monitoring and control over industrial networks, such as smart factories. The 2 RS – 232 serial ports and 1 CAN bus interface provide additional flexibility, allowing seamless connection with legacy industrial devices and other CAN – based systems. The presence of storage interfaces like the CompactFlash slot and SATA interface ensures efficient data storage and retrieval. This combination of interfaces makes the MVME3100 suitable for a wide range of industrial scenarios, from modernizing older plants to building state – of – the – art automation systems.

Expandability and flexibility

With 2 PMC expansion slots, the MVME3100 offers excellent expandability. Users can add specialized PMC cards to enhance the functionality of the module according to specific application requirements. This could include adding more communication interfaces, specialized data processing capabilities, or enhanced storage options. The ability to customize the module in this way makes the MVME3100 highly adaptable, ensuring it can meet the evolving needs of industrial automation projects over time.

MVME3100

Typical application scenarios

Industrial automation and smart manufacturing

In smart manufacturing plants, the Motorola MVME3100 plays a pivotal role. It can connect to a multitude of sensors on the production line, such as those monitoring temperature, pressure, and product quality. By analyzing the data collected from these sensors in real – time, the MVME3100 can optimize the production process. For example, it can adjust the speed of conveyor belts, control the operation of robotic arms, and ensure the quality of products. Its high – speed Ethernet ports enable seamless communication with other devices in the factory network, facilitating the integration of the production line with enterprise – level management systems for better resource planning and production scheduling.

Process control in energy plants

In power generation and oil & gas plants, the MVME3100 is essential for process control. It interfaces with sensors that measure critical parameters like the temperature and pressure of turbines in a power plant or the flow rate of crude oil in an oil refinery. The module can analyze this data in real – time and send control signals to regulate the operation of equipment. In case of any anomalies, it can trigger alarms and initiate corrective actions to ensure the safe and efficient operation of the plant. The CAN bus interface is particularly useful for connecting to distributed control systems within the plant, enabling reliable communication between different control units.

Telecommunications infrastructure

The MVME3100 also finds applications in telecommunications infrastructure. Its high – performance processing and multiple Gigabit Ethernet ports make it suitable for tasks such as data routing, network management, and edge computing in communication networks. It can handle the processing and transmission of large amounts of data in real – time, ensuring the smooth operation of mobile networks, data centers, and other communication systems.

Related model recommendations

MVME5100

The MVME5100 is part of the same product family and offers similar high – performance capabilities. It features an integrated MPC8540 SoC processor and supports a wide range of interfaces. While the MVME3100 focuses on the Freescale MPC8548 processor, the MVME5100 can be an alternative for applications that require a different processing architecture or specific interface combinations.

MVME2434

The MVME2434 is a lower – end model compared to the MVME3100. It has different processing power and memory capacity. The MVME2434 can be used in applications where less – intensive processing and lower costs are acceptable, while the MVME3100 is suitable for more demanding, high – performance industrial applications.

MVME167 – 012

This model has a different design and functionality. The MVME167 – 012 may be more suitable for applications with specific I/O requirements or for use in legacy systems where compatibility is a key factor. In contrast, the MVME3100 offers advanced processing and more modern connectivity options for contemporary industrial automation needs.

MVME7124

The MVME7124 is another VMEbus – based module. It has its own unique features, such as different I/O configurations and processing capabilities. The MVME7124 can be used in combination with the MVME3100 in complex industrial systems, where each module can handle specific tasks, leveraging their respective strengths.

MVME3104

The MVME3104 is closely related to the MVME3100. It may have some minor variations in features, such as different memory configurations or additional interface options. The MVME3104 can be considered as a variant for applications that require specific customizations based on the foundation provided by the MVME3100.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Motorola MVME3100, ensure that the VMEbus backplane is properly configured and powered off. The installation environment should have an ambient temperature within the 0°C – 55°C range and be free from excessive dust and moisture. Use anti – static wrist straps and appropriate tools to handle the module to prevent electrostatic damage to its sensitive components. Carefully align the MVME3100 with the VMEbus slot and gently insert it, ensuring a secure mechanical and electrical connection. Connect the power supply cables according to the provided wiring diagram, verifying that the +5 VDC and +12 VDC power sources are stable and within the specified tolerance levels. Also, ensure that all external devices connected to the module’s communication and storage interfaces are properly configured before powering on the system.

Maintenance suggestions

Regularly inspect the MVME3100 for any signs of physical damage, such as bent pins on the VMEbus connector or cracks on the circuit board. Clean the module using a static – free, dry cloth to remove dust, especially around the ventilation areas and connectors. Periodically run diagnostic software to test the functionality of all interfaces, including Ethernet ports, serial ports, CAN bus, and storage interfaces. If any issues are detected, start by checking the physical connections, power supply voltages, and cable integrity. When replacing components, such as memory modules or PMC cards, always use genuine Motorola replacement parts to maintain the module’s reliability and compatibility. Keep a detailed record of all maintenance activities, including the date of inspection, any issues found, and the actions taken to resolve them, for future reference.

Service and guarantee commitment

Motorola stands firmly behind the Motorola MVME3100. Every unit of the MVME3100 undergoes rigorous quality control processes during manufacturing to meet the highest international standards. Motorola offers a comprehensive warranty period, covering any manufacturing defects that may occur. In case of issues during the warranty period, Motorola’s global technical support team, consisting of highly skilled engineers, is readily available. They can provide detailed guidance on installation, efficient troubleshooting, and maintenance advice through various channels, including online support and technical documentation. Motorola also invests continuously in research and development, and may release software updates and firmware upgrades to enhance the functionality and compatibility of the MVME3100. This commitment reflects Motorola’s confidence in the product’s quality and its dedication to ensuring customer satisfaction in the industrial computing domain.