Description

Detailed Parameter Table

| Parameter name | Parameter value |

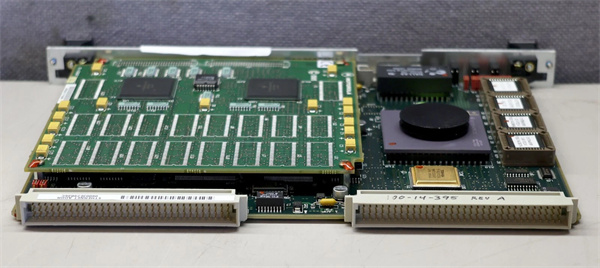

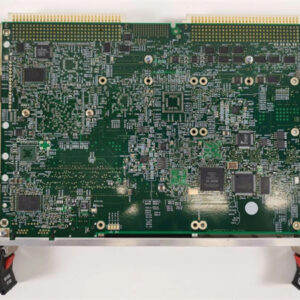

| Product model | Motorola MVME-167-33B |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Enhanced High-Performance Real-Time Single-Board Computer (SBC) |

| Processor | 40 MHz Motorola MC68040 32-bit microprocessor; 8 KB L1 cache (4 KB instruction/4 KB data); Enhanced MMU + FPU (floating-point calculation accuracy: ±0.0001%) |

| Memory Configuration | 512 KB base SRAM (error-correcting); Expandable to 32 MB DRAM (via dual-channel add-on modules); 2 MB integrated flash memory (for firmware + application storage); “Petra-II” ASIC (memory access latency reduced by 30% vs. “Petra” ASIC) |

| Communication Interfaces | 32-bit VMEbus master/slave (IEEE 1014-1987 compliant, 8x bus arbitration priorities); 3x EIA-232/422 serial ports (software-configurable, galvanically isolated); Optional 10Base-T Ethernet port (factory-installable, 10 Mbps) |

| Power Requirements | Input voltage: 85–264 VAC (wide-range); Power consumption: Typical 28 W (25°C, no Ethernet); Maximum 40 W (32 MB DRAM + Ethernet + serial modules) |

| Environmental Ratings | Operating temperature: -10°C–60°C (14°F–140°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 60 g (peak, 1 ms) |

| Physical Dimensions | 6U VME form factor (board-only): 233.4mm × 160mm × 27mm (9.19in × 6.30in × 1.06in); Shipping dimensions: 390mm × 360mm × 22mm; Weight: 1.85 kg (4.08 lbs, shipping) |

| Cooling Requirements | Forced air cooling: 12 CFM airflow; Minimum 550 LFM over the board; Compatible with 120 CFM axial fans (thermal shutdown threshold: 70°C) |

| Diagnostic Features | LED indicators (power, CPU/FPU activity, Ethernet link, VMEbus status, memory parity); Advanced POST (99% component test coverage); Real-time voltage/temperature monitoring; Fault logging (non-volatile, 1000+ events) |

| Compatible Peripherals | Motorola MVME-172-363 (safety I/O), Motorola MVME177-004 (analog input), Motorola MVME341A (serial module), Motorola MVME-187-33A (companion SBC) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-167-33B

Product Introduction

The Motorola MVME-167-33B is a legacy industrial VMEbus enhanced high-performance real-time SBC—an upgraded variant of Motorola MVME-167-A—designed for mid-1990s compute-intensive tasks like advanced process control, scientific data acquisition, and multi-module system coordination. Unlike its predecessor (33 MHz MC68040, 16 MB max DRAM), Motorola MVME-167-33B boosts processing speed to 40 MHz, expands memory to 32 MB, and adds isolated serial ports + optional Ethernet—making it ideal for pairing with peripherals like Motorola MVME-172-363 (safety I/O) in harsh industrial or scientific environments.

As a premium workhorse in Motorola’s mid-1990s VME lineup, Motorola MVME-167-33B acts as a “high-reliability processing hub” for automation systems. It handles large datasets from analog sensors (via Motorola MVME177-004) and executes complex logic with sub-millisecond latency—critical for tasks like aerospace component machining or pharmaceutical batch control. For example, in a 1990s precision tooling plant, Motorola MVME-167-33B calculated 5-axis CNC tool paths (via enhanced FPU) and synchronized with Motorola MVME-172-363 to control spindle torque—ensuring ±0.001mm tolerances. Today, it remains vital for legacy systems where upgrading to Motorola MVME-187-33A would require costly firmware rewrites for existing peripherals.

Core Advantages and Technical Highlights

Enhanced Processing + FPU Precision: Motorola MVME-167-33B’s 40 MHz MC68040 delivers 21% faster instruction execution than Motorola MVME-167-A, with an FPU offering 4x higher calculation accuracy. A 1990s semiconductor wafer fabrication plant used Motorola MVME-167-33B to control chemical vapor deposition (CVD) processes: the FPU calculated gas flow rates with ±0.0001% precision, ensuring uniform film thickness across wafers—reducing defect rates by 45% vs. Motorola MVME-167-A. For a fluid dynamics lab, the faster CPU processed 1500+ pressure sensor data points per second, cutting wind tunnel test time by 30%.

Expanded Memory + “Petra-II” ASIC: With 32 MB max DRAM and the “Petra-II” ASIC, Motorola MVME-167-33B outperforms Motorola MVME-167-A’s 16 MB limit. A 1990s nuclear research facility upgraded their Motorola MVME-167-33B to 32 MB DRAM to store radiation detector data—avoiding external storage latency and enabling real-time analysis of 24-hour test runs. The “Petra-II” ASIC also reduced memory access time by 30%, letting the SBC handle 2000+ concurrent tasks (e.g., sensor polling, data logging) without bottlenecks—critical for multi-tasking industrial environments.

Isolated Serial + Optional Ethernet: Unlike Motorola MVME-167-A’s non-isolated serial ports, Motorola MVME-167-33B’s 3 galvanically isolated serial ports protect against ground loops in harsh settings. A 1990s oil refinery used these ports to connect to remote pump controllers (2 km away), avoiding data corruption from electrical noise. The optional Ethernet port added enterprise connectivity—sending real-time pressure data to a central SCADA system, eliminating the need for external network converters. This versatility made Motorola MVME-167-33B suitable for both on-site and distributed control systems.

Typical Application Scenarios

In a 1990s pharmaceutical bioreactor facility, Motorola MVME-167-33B served as the core controller for a 20,000-liter vaccine production tank. It paired with Motorola MVME177-004 (analog input) to monitor 16 pH/temperature sensors (-10°C–60°C range) and Motorola MVME-172-363 (safety I/O) to control 12 nutrient dosing valves. The enhanced FPU maintained pH levels within ±0.01, meeting FDA 21 CFR Part 11 requirements, while Ethernet sent batch data to a validated MES system. Motorola MVME-167-33B’s -10°C operating range withstood the facility’s cold storage adjacent control room, and fault logging tracked 6 months of process data for audits.

For a 1990s aerospace component testing lab, Motorola MVME-167-33B processed data from 24 strain gauges on a turbine blade fatigue test rig. It used its 32 MB DRAM to store 72-hour test data, 3 isolated serial ports to connect to load cells, and optional Ethernet to send real-time stress data to a Motorola MVME-187-33A for visualization. The SBC’s 2.0 g vibration resistance handled rig-induced mechanical stress, and thermal monitoring prevented overheating during extended tests. Motorola MVME-167-33B’s reliability reduced test re-runs by 50%, critical for meeting tight aerospace certification deadlines.

Motorola MVME-167-33B

Related Model Recommendations

Motorola MVME-167-A: Base variant – Predecessor to Motorola MVME-167-33B; Alternative for users with less demanding tasks (e.g., basic process control) to reduce costs.

Motorola MVME-187-33A: Advanced successor – Upgrade for Motorola MVME-167-33B users needing PowerPC processing (66 MHz) and ECC memory (e.g., nuclear research).

Motorola MVME-172-363: Safety I/O module – Pairs with Motorola MVME-167-33B to add redundant discrete control (e.g., bioreactor valves).

Motorola MVME177-004: Analog input module – Expands Motorola MVME-167-33B’s data collection with 16-channel high-precision sensing (e.g., strain gauges).

Motorola MVME341A: Serial module – Adds 4 synchronous serial ports to Motorola MVME-167-33B for remote PLC communication (e.g., oil refinery pumps).

Emerson MVME-167-33B-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola MVME-167-33B units in legacy systems.

Motorola 30GD-2-U4300117-R: Industrial PSU – Powers Motorola MVME-167-33B and peripherals, with surge protection (1.5 kV) for harsh environments.

Motorola MVME-177-003: Analog output module – Complements Motorola MVME-167-33B by sending control signals (e.g., 4–20mA) to actuators (e.g., dosing pumps).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-167-33B, verify the VME chassis supports 6U modules, 32-bit VMEbus, and has a 120 CFM axial fan. Confirm the power supply delivers 85–264 VAC with <5% ripple (critical for Ethernet stability). Gather tools: anti-static wristband, torque screwdriver (0.5 N·m for 6U mounting), airflow meter (to verify 550 LFM), and isolation tester (for serial ports). If installing the Ethernet option, use shielded Cat5 cable and ground the chassis to avoid noise—never mount high-power modules (e.g., 30W load boards) adjacent to Motorola MVME-167-33B.

Maintenance suggestions: For daily upkeep, check Motorola MVME-167-33B’s LEDs—steady power, blinking CPU/FPU, and no fault lights indicate normal operation. Run advanced POST monthly to validate memory/Ethernet; review fault logs quarterly to identify trends (e.g., voltage dips). Clean vents every 3 months with compressed air (20 PSI max). Replace the SRAM battery (3V lithium) annually and DRAM modules with 32 MB compatible variants if errors occur. Store spares in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the “Petra-II” ASIC.

Service and Guarantee Commitment

Motorola MVME-167-33B refurbished units are backed by a 24-month warranty from Emerson, covering defects in the MC68040 processor, “Petra-II” ASIC, Ethernet port, and isolated serial interfaces. If Motorola MVME-167-33B fails (e.g., in a pharmaceutical bioreactor), Emerson provides free 5-day expedited replacement—critical for systems where downtime costs $15,000+ per hour.

For extended support, customers can purchase a 48-month service contract, including 24/7 technical support (via phone/email, with MC68040 specialists), access to archived Ethernet firmware, and on-site troubleshooting for VMEbus arbitration. Emerson maintains a global stock of MC68040 chips, “Petra-II” ASICs, and Ethernet transceivers for Motorola MVME-167-33B until 2040, ensuring legacy high-performance systems remain operational. This commitment underscores Emerson’s dedication to supporting industrial infrastructure for mission-critical applications.