Description

Detailed Parameter Table

| Parameter name | Parameter value |

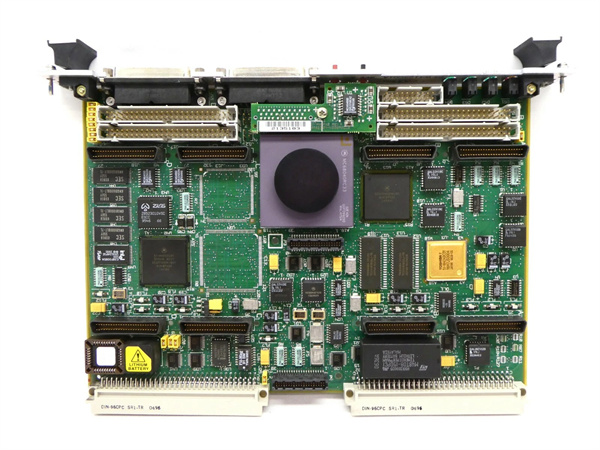

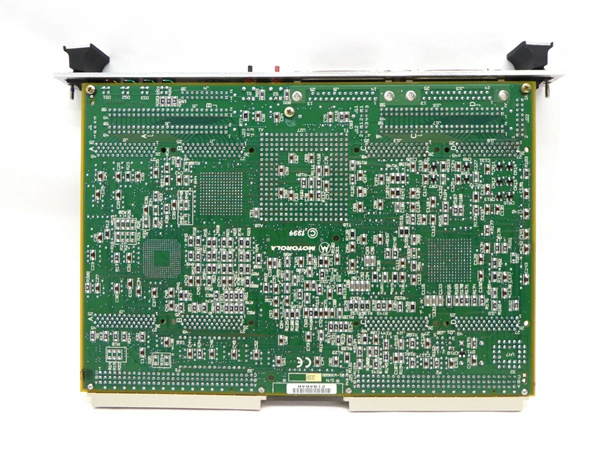

| Product model | Motorola MVME-172-533 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Mid-Density Digital I/O Module |

| I/O Channels | 32 discrete channels (16 input/16 output); Fixed channel grouping (no reconfiguration) |

| Input Type | TTL-compatible (5V); Optically isolated (1500V AC rms); Debounce time: 0.5–5 ms (software-configurable) |

| Output Type | Open-collector transistor (max 300 mA per channel); Overcurrent protection (fuse-based, replaceable); Basic status feedback per 8-channel group |

| Communication Interface | VMEbus A16/D16 slave (IEEE 1014-1987 compliant); Polled or interrupt-driven data transfer (selectable) |

| Environmental Ratings | Operating temperature: -30°C–65°C (-22°F–149°F); Storage temperature: -55°C–125°C (-67°F–257°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.8 g (rms); Shock: 50 g (peak, 1 ms); EMC Compliance: CISPR 22 Class A, IEC 61000-6-3 |

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 22mm (3.94in × 6.30in × 0.87in); Weight: 420 g (0.93 lbs) |

| Power Consumption | Typical: 8 W (25°C, 50% input/output activation); Maximum: 12 W (all channels active, max load per output) |

| Diagnostic Features | LED indicators (power, module ready, input status per 8-channel group, output fault per 8-channel group); Overcurrent detection per output group; Module-level self-test |

| Compatible SBCs | Motorola MVME162-533, Motorola MVME162-532, Motorola MVME-187-33A, Motorola MVME162-413 |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME162-510

Product Introduction

The Motorola MVME-172-533 is a legacy industrial VMEbus mid-density digital I/O module designed to balance channel count, cost, and reliability for mid-1990s mid-scale industrial control systems. Unlike high-density Motorola MVME172PA-642SE (64 channels, double-high form factor) or low-density Motorola MVME172-001 (16 channels), Motorola MVME-172-533 offers 32 channels (16 in/16 out) in a compact single-high 3U form—making it ideal for pairing with mid-tier SBCs like Motorola MVME162-533 to control applications such as small assembly lines, packaging machines, or regional water pump stations.

As a versatile I/O component in Motorola’s VME lineup, Motorola MVME-172-533 acts as a “mid-scale discrete control link” between field devices and control systems. It converts sensor signals (e.g., “package detected” from a photoelectric sensor) into digital data for SBCs and sends output commands (e.g., “start sealing” for a packaging machine) to actuators. For example, in a mid-1990s small-scale electronics assembly plant, Motorola MVME-172-533 monitored 16 component presence sensors and controlled 16 placement actuators—its optical isolation preventing noise from nearby soldering equipment from disrupting signals. Today, it remains critical for legacy mid-scale systems where upgrading to high-density modules would waste chassis space and increase costs unnecessarily.

Core Advantages and Technical Highlights

Mid-Density Efficiency for Space-Conscious Systems: Motorola MVME-172-533’s 32 channels in a single-high 3U form factor delivers twice the density of Motorola MVME172-001 without the space requirements of Motorola MVME172PA-642SE (double-high). A mid-1990s regional bakery used two Motorola MVME-172-533 modules to manage 64 discrete signals (32 in/32 out) for a bread packaging line: this setup fit in 2 chassis slots, whereas four Motorola MVME172-001 modules would have needed 4 slots—cutting chassis size by 50% and reducing wiring complexity. For a small water treatment plant, a single Motorola MVME-172-533 handled 16 pump status sensors and 16 valve actuators—avoiding the unused 48 channels of Motorola MVME172PA-642SE.

Balanced Isolation and Protection: With 1500V AC optical isolation and group-level overcurrent protection, Motorola MVME-172-533 delivers industrial-grade reliability without the premium of Motorola MVME172PA-642SE’s per-channel isolation. A mid-1990s rural wastewater plant used Motorola MVME-172-533 to control 16 aeration valves: its isolation protected the module from ground loops in the plant’s aging wiring, while group-level overcurrent protection shut down a faulty valve bank before damage spread. This reliability cost 30% less than Motorola MVME172PA-642SE, critical for budget-constrained municipal facilities.

Flexible Data Transfer for Mid-Scale Workloads: Motorola MVME-172-533 supports both polled and interrupt-driven data transfer—adapting to varying real-time needs. A mid-1990s packaging machine used interrupt-driven mode for 16 “package jam” input sensors (ensuring instant alerts), while using polled mode for 16 non-critical output status checks (reducing SBC CPU load). This flexibility let the paired Motorola MVME162-533 SBC prioritize critical tasks, improving overall system responsiveness. Basic modules like Motorola MVME172-001 only support polled transfer, leading to delays in critical fault detection.

Typical Application Scenarios

In a mid-1990s small-scale automotive parts stamping plant, Motorola MVME-172-533 paired with Motorola MVME162-533 to manage the stamping press’s safety and control systems. The module monitored 16 input signals (e.g., guard door position, press ram limit switches) and controlled 16 output devices (e.g., feed rollers, emergency stop relays). Its 1500V AC isolation protected against electrical noise from the press’s hydraulic system, while group-level overcurrent protection prevented damage from a shorted feed roller motor. Motorola MVME-172-533’s -30°C–65°C operating range withstood the plant’s seasonal temperature swings, and its single-high form factor fit in the press’s compact control cabinet—something the double-high Motorola MVME172PA-642SE could not.

For a mid-1990s retail distribution center’s small parcel sorting system, Motorola MVME-172-533 managed 16 proximity sensors (detecting parcels on 4 conveyor lanes) and 16 sorting gate actuators. It sent sensor data to a Motorola MVME162-413 SBC, which directed gates to route parcels to the correct shipping zones. The module’s configurable debounce (2 ms) filtered out vibration-induced false signals from the conveyors, while group-level fault LEDs quickly identified a faulty gate actuator bank. During a power fluctuation, the module’s self-test feature verified functionality on restart—avoiding manual checks and reducing downtime by 2 hours compared to non-self-testing modules like Motorola MVME172-001.

Motorola MVME162-510

Related Model Recommendations

Motorola MVME162-533: Mid-tier SBC – Primary pairing for Motorola MVME-172-533; Processes mid-volume discrete I/O data for applications like small stamping plants.

Motorola MVME172PA-642SE: High-density variant – Upgrade for Motorola MVME-172-533 users scaling to 64 channels (e.g., expanding to multi-line packaging systems).

Motorola MVME172-001: Low-density variant – Alternative for Motorola MVME-172-533 users with <16 channels (e.g., single-machine control) to reduce costs.

Motorola MVME177-001: Basic analog input module – Complement to Motorola MVME-172-533; Adds 4-channel analog monitoring (e.g., temperature) for mixed-signal systems like water pumps.

Emerson MVME-172-533-R: Refurbished variant – Tested to original isolation and I/O specs; Critical replacement for failing Motorola MVME-172-533 units in legacy mid-scale systems.

Motorola MVME340B: Entry-level serial module – Expands systems using Motorola MVME-172-533; Sends I/O status to local HMI panels via RS-232.

Motorola 30GD-1-U4300099: Industrial DC PSU – Powers Motorola MVME-172-533 and paired SBCs, ensuring stable +5V/+12V for reliable I/O operation.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-172-533, verify the VME chassis supports single-high 3U modules and A16/D16 addressing (compatible with SBCs like Motorola MVME162-533). Confirm the power supply provides +5V DC (±5%) and +12V DC (±10%) – use a multimeter to check ripple (<50 mV, critical for digital signal stability). Gather tools: anti-static wristband (protects module circuitry), torque screwdriver (0.3 N·m for 3U mounting), and wire strippers (for 24–18 AWG wires to terminal blocks). Label input/output wires by channel and function (e.g., “Conveyor 2 Parcel Sensor”) to avoid misconfiguration; secure ground connections tightly to maximize isolation effectiveness.

Maintenance suggestions: For daily upkeep, check Motorola MVME-172-533’s LEDs – steady power, “module ready” light, and no group fault indicators mean normal operation. Test input channels monthly by triggering connected sensors (e.g., activating limit switches) and verifying data reception on the host SBC. For outputs, activate each group and confirm actuator response + fault LED status. Inspect terminal blocks quarterly for loose wires or corrosion (common in humid distribution centers). Replace output group fuses (300 mA, fast-blow) only with identical ratings if a fault occurs. Store spare Motorola MVME-172-533 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve optical isolation components.

Service and Guarantee Commitment

Motorola MVME-172-533 is backed by an 18-month warranty from Emerson for refurbished units, covering defects in the optical isolation circuits, output transistors, and communication interface. If Motorola MVME-172-533 fails (e.g., in a small stamping plant), Emerson provides free 10-day replacement—with pre-validated I/O and isolation performance to avoid downtime for reconfiguration.

For extended support, customers can purchase a 36-month service contract, including weekday technical support (via phone/email, with digital I/O specialists), access to archived configuration guides, and remote troubleshooting for data transfer mode setup. Emerson maintains a global stock of optical isolators and replacement fuses for Motorola MVME-172-533 until 2038, ensuring legacy mid-scale systems retain reliable discrete control. This commitment underscores Emerson’s dedication to balancing cost and performance for industrial users with moderate I/O needs.