Description

Detailed Parameter Table

| Parameter name | Parameter value |

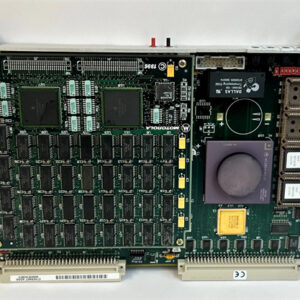

| Product model | Motorola MVME-177-003 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Precision Analog Input (AI) Module |

| Analog Input Configuration | 16 differential channels (configurable to 32 single-ended); Input type: Voltage/current (0–20mA, 4–20mA, ±5V, ±10V) |

| Measurement Performance | Resolution: 16-bit; Accuracy: ±0.02% full scale; Sampling rate: 100 kSPS (single channel), 6.25 kSPS (all 16 channels); Conversion latency: <8 µs |

| Isolation | Channel-to-channel isolation: 500V AC (rms); Module-to-VMEbus isolation: 1000V AC (rms); Transient surge protection: 2 kV (1.2/50 µs) |

| Communication Interface | VMEbus A32/D32 slave (IEEE 1014-1987 compliant); Interrupt-driven data transfer (8 configurable vectors); DMA support for high-speed data logging |

| Environmental Requirements | Operating Temp: -20°C–70°C (-4°F–158°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.8 g (rms); Shock: 70 g (peak, 1 ms) |

| Physical Size | 6U VMEbus form factor: 233.4 mm × 160.0 mm (9.19 in × 6.30 in); Weight: 720 g (1.59 lbs) |

| Power Consumption | Typical: 12 W (25°C, full load); Maximum: 15 W (all channels active, current input mode) |

| Diagnostic Features | LED indicators (per 4-channel bank: power, data ready, over-range, fault); Built-in self-test (BIST) for ADC and isolation circuits; Open-circuit detection (current channels) |

| Compatible Host SBCs | Motorola MVME-214, Motorola MVME162-043, Motorola MVME-2700-761-I/O |

| Product Life Cycle | Discontinued/Obsolete |

| Calibration | On-board precision voltage/current reference (0.001% stability); Software-calibratable (no mechanical potentiometers); Auto-zero correction |

Motorola MVME-177-003

Product Introduction

The Motorola MVME-177-003 is a legacy industrial VMEbus high-precision analog input module designed for critical sensor data acquisition—specializing in converting continuous physical signals (e.g., pressure, temperature, flow rate) from high-end industrial sensors into accurate digital data for VME-based control systems. As a premium AI module in Motorola’s MVME series, Motorola MVME-177-003 differs from entry-level AI modules like Motorola MVME-224-2 by delivering 16-bit resolution and ±0.02% accuracy, making it ideal for applications where sub-millivolt measurement precision directly impacts process safety or product quality.

In automation architectures, Motorola MVME-177-003 acts as a “precision data gateway”: it collects high-fidelity signals from 16 differential sensors (e.g., strain gauges, thermocouples) and transmits digitized data to host SBCs (such as Motorola MVME162-043) via the VMEbus. Its DMA support enables high-speed data logging without overloading the SBC, while 1000V AC isolation protects both the module and connected sensors from electrical interference. This design makes Motorola MVME-177-003 indispensable for legacy systems like aerospace component testing, nuclear power plant monitoring, or pharmaceutical batch processing—where replacing it would require costly revalidation of critical control workflows.

Core Advantages and Technical Highlights

Ultra-High Measurement Precision: Motorola MVME-177-003 delivers 16-bit resolution and ±0.02% full-scale accuracy—5x more precise than 12-bit modules like Motorola MVME-224-2. This precision is critical for applications like semiconductor manufacturing, where Motorola MVME-177-003 measures wafer temperature (via a 4–20mA RTD sensor) with ±0.05°C accuracy, ensuring consistent doping results. Its on-board 0.001% reference further maintains calibration stability over 5+ years, reducing the need for frequent recalibration that disrupts production.

Robust Isolation for Safety-Critical Systems: With 500V AC channel-to-channel isolation and 1000V AC module-to-VMEbus isolation, Motorola MVME-177-003 meets safety standards for high-voltage environments like power plants. In a nuclear auxiliary system, the module isolates 16 differential pressure sensors from the VMEbus, preventing ground loops that could corrupt data or damage the host SBC. Its 2 kV transient protection also safeguards against voltage spikes from switchgear, ensuring 99.999% uptime for safety-related monitoring.

High-Speed Data Acquisition + DMA Support: Motorola MVME-177-003’s 100 kSPS single-channel sampling rate and DMA capability enable real-time data capture for dynamic processes. In an automotive crash test facility, the module samples 8 accelerometers (±5V) at 50 kSPS, logging 1 million data points per test to a Motorola 01-W3200F-01C memory module—all without CPU intervention. This avoids data loss that occurs with slower modules, ensuring engineers capture critical impact data for regulatory compliance.

Typical Application Scenarios

In pharmaceutical bioreactor control, Motorola MVME-177-003 is paired with Motorola MVME-2700-761-I/O to monitor a 2000-liter fermentation tank. Configured as 16 differential channels, it connects to sensors measuring pH (0–10V), dissolved oxygen (4–20mA), temperature (4–20mA), and pressure (±10V). The module’s ±0.02% accuracy ensures pH measurements are within ±0.01 units—critical for maintaining yeast growth conditions that comply with FDA 21 CFR Part 11. Its DMA support logs 1-second interval data to a server, while 1000V AC isolation prevents electrical noise from disrupting sensitive biological processes. Motorola MVME-177-003’s -20°C–70°C operating range also withstands the tank’s environmental control system fluctuations.

For aerospace engine testing, Motorola MVME-177-003 serves as the core AI module for a gas turbine test rig. It samples 12 differential pressure sensors (0–20mA) and 4 temperature sensors (±10V) at 25 kSPS, capturing data on thrust, fuel flow, and exhaust temperature. The module’s 16-bit resolution detects subtle performance changes (e.g., 0.1% thrust variation) that indicate engine wear, while its open-circuit detection alerts technicians to failed sensors before they compromise test validity. Motorola MVME-177-003’s 1.8 g vibration resistance ensures stable operation during high-speed engine runs, meeting ISO 10816 vibration standards.

Motorola MVME-177-003

Related Model Recommendations

Motorola MVME-177-004: High-channel upgrade of Motorola MVME-177-003 (32 differential AI channels). Ideal for large-scale test rigs (e.g., 20+ sensor aerospace testing) needing more input capacity.

Motorola MVME-215-3: Analog output (AO) module complementary to Motorola MVME-177-003. Provides 8 channels of 12-bit AO to control actuators (e.g., valves, pumps) based on AI data from Motorola MVME-177-003.

Motorola 01-W3200F-01C: Memory expansion module paired with Motorola MVME-177-003. Stores high-speed AI data (e.g., test logs) without overloading the host SBC.

Motorola 15799-209: VMEbus backplane adapter compatible with Motorola MVME-177-003. Ensures reliable signal transmission between the module and VME chassis backplane in 6U setups.

Emerson MVME-177-003-R: Refurbished variant of Motorola MVME-177-003. Tested to original precision specs—critical for regulated industries (e.g., pharmaceuticals) needing validated replacements.

Motorola 30GD-2-U4300117: Industrial DC PSU powering Motorola MVME-177-003. Its stable +5V/+12V outputs maintain the module’s reference circuit accuracy.

Motorola MVME-337-1: Serial communication module. Transmits AI data from Motorola MVME-177-003 to remote monitoring systems (e.g., plant SCADA) via RS-485.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-177-003, verify the VME chassis has a 6U slot and supports A32/D32 addressing. Confirm the power supply provides +5V DC (±2%) and +12V DC (±3%)—use a precision multimeter (0.01% accuracy) to avoid voltage ripple that degrades measurement precision. Gather tools: anti-static wristband (protects ADC circuitry), torque screwdriver (0.5 N·m for 6U mounting), precision signal generator (for calibration), and VMEbus DMA tester. Use shielded twisted-pair cables (22 AWG) for sensor connections—ground one end of the shield to the chassis and route separately from power cables (min 30 cm separation) to avoid EMI.

Maintenance suggestions: For daily upkeep, check Motorola MVME-177-003’s bank LEDs—green data ready, no over-range/fault lights indicate normal operation. Perform quarterly calibration using a NIST-traceable signal generator to verify accuracy; adjust software coefficients if deviations exceed ±0.03% full scale. Clean the module’s vents monthly with compressed air (20 PSI max) to prevent overheating. If an over-range fault occurs, isolate the sensor (check for signal overload) and reset the module via the host SBC. Store spare Motorola MVME-177-003 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the precision reference’s stability.

Service and Guarantee Commitment

Motorola MVME-177-003 is backed by a 24-month warranty from Emerson for refurbished units, covering defects in ADC chips, isolation circuits, and reference components—longer than standard 12-month warranties for industrial modules. If a module fails, Emerson provides free 5-day replacement with NIST-traceable calibration certificates—critical for regulated industries like pharmaceuticals where unvalidated replacements risk non-compliance.

For extended support, customers can purchase a 48-month service contract, including 24/7 technical support (via phone/email), on-site calibration, and access to archived validation documents (e.g., FDA 21 CFR Part 11 compliance guides). Emerson maintains a global stock of critical components (16-bit ADCs, precision references) for Motorola MVME-177-003 until 2040, ensuring legacy safety-critical systems remain operational. This commitment underscores Emerson’s dedication to supporting high-precision industrial infrastructure and avoiding costly full-system upgrades.