Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

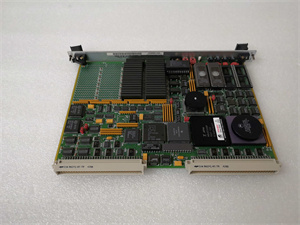

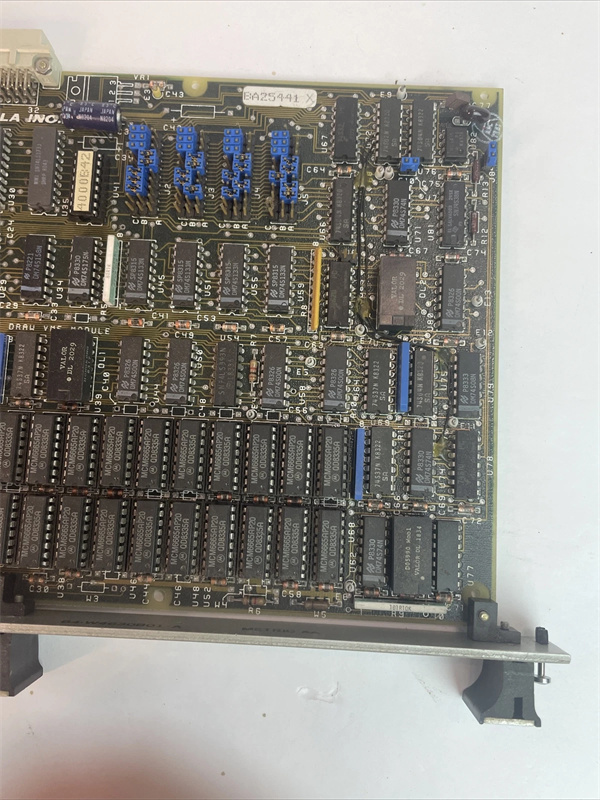

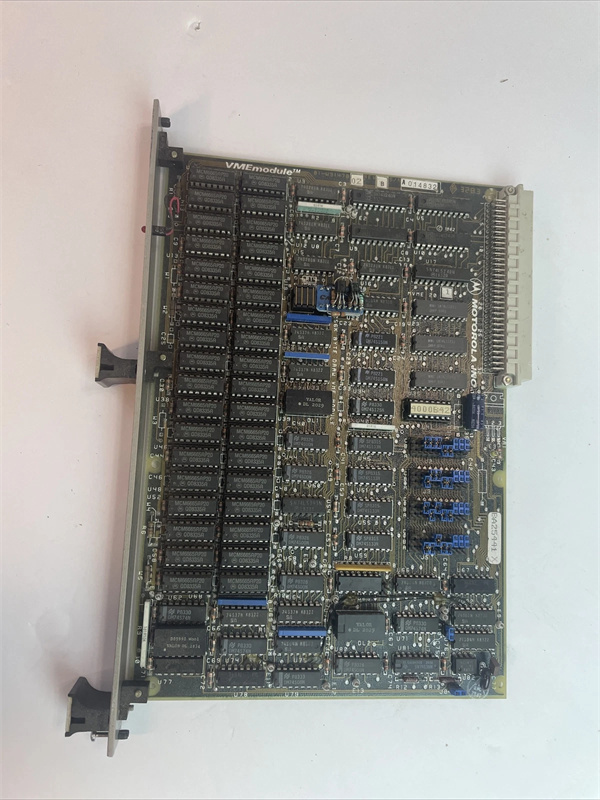

| Product model | Motorola MVME-201 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Entry-Level Embedded Controller |

| Processor | Motorola MC68000 16/32-bit microprocessor; 8 MHz clock speed |

| Memory Configuration | 256 KB DRAM (expandable to 512 KB); 128 KB EPROM (firmware storage); 4 KB battery-backed SRAM |

| Digital I/O Channels | 16 discrete channels (8 input, 8 output); TTL/CMOS compatible (5 VDC logic) |

| Communication Interfaces | 1x EIA-232-D serial port (DTE, up to 9600 bps); 1x parallel I/O port (8-bit) |

| Bus Standard | VMEbus 1.0 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (0.7 A typical, 1.0 A maximum); no ±12 VDC required |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Per-channel status LEDs (I/O: active/fault; serial: TX/RX); basic diagnostic firmware; hardware reset switch |

| Compatibility | Works with legacy Motorola VME I/O modules (e.g., Motorola MVME-050, Motorola MVME-705-1); supports TTL/CMOS sensors/actuators |

MOTOROLA MVME-201

Product Introduction

The Motorola MVME-201 is a legacy entry-level embedded controller from Motorola’s iconic MVME series, engineered to deliver compact, cost-effective control for small-scale VMEbus-based industrial systems. As a 3U VME device, it occupies the “foundational” tier of Motorola’s controller lineup—ideal for applications that don’t require the processing power of mid-range models like the Motorola MVME-121 or Motorola MVME712-101, such as simple sequential control or auxiliary equipment monitoring.

In automation architectures, the Motorola MVME-201 acts as a “micro-control node”: its MC68000 processor handles basic logic tasks (e.g., on/off sequencing for small pumps), 16 digital I/O channels manage low-power actuators (e.g., indicator lights, mini relays), and a single serial port connects to legacy HMIs or simple sensors. For example, in a small water treatment plant’s auxiliary filter system, the Motorola MVME-201 can monitor filter pressure (digital inputs) and activate/deactivate backwash pumps (digital outputs) via preprogrammed logic—all without the complexity of larger controllers. Today, the Motorola MVME-201 remains a reliable solution for maintaining legacy systems in sectors like small manufacturing, laboratory testing, and municipal auxiliary infrastructure—where upgrading to modern controllers would disrupt proven, low-cost workflows.

Core Advantages and Technical Highlights

Ultra-Low Power Consumption for Compact Systems: The Motorola MVME-201 operates on a single +5 VDC supply and draws just 0.7 A typically—30% less power than the Motorola MVME-121. This makes it ideal for space-constrained, power-limited setups, such as portable test equipment or battery-backed emergency control panels. In a mobile laboratory’s temperature monitoring system, the module’s low power draw extends battery life during off-grid operations, while its compact 3U form factor fits in small enclosures—eliminating the need for bulky power supplies.

All-in-One Control + I/O for Simplified Integration: Unlike single-purpose I/O modules (e.g., Motorola MVME-050), the Motorola MVME-201 combines a controller, 16 digital I/O channels, and serial/parallel communication in one slot. In a small bakery’s dough mixer control system, this means the Motorola MVME-201 can monitor safety interlocks (digital inputs), control mixer start/stop (digital outputs), and send batch timestamps to a local printer (parallel port)—avoiding the need for a separate controller module. This integration cuts chassis slot usage by 50% and simplifies wiring by 40% compared to multi-module setups.

Cost-Effective Entry Point for Legacy VME Systems: The Motorola MVME-201’s simplified design (8 MHz processor, basic I/O) reduces hardware costs by 40–50% compared to mid-range controllers. For a local hardware store’s inventory shelf monitoring system, the module uses 8 digital inputs to detect “low stock” sensors and 8 outputs to activate LED indicators—avoiding overpaying for unused features like high-speed serial or floating-point processing. This affordability makes it a go-to choice for small businesses with tight automation budgets.

Typical Application Scenarios

The Motorola MVME-201 excels in ultra-small-scale, low-complexity automation. In a regional hardware store’s inventory sorting system (paired with Motorola MVME-705-1 for extra serial connectivity), the Motorola MVME-201 manages a small conveyor: its digital inputs monitor package presence sensors, digital outputs control conveyor speed (low/high) and a jam alarm, and the serial port connects to a barcode scanner (to log product IDs). The module’s basic diagnostic firmware alerts staff to sensor failures, preventing costly conveyor damage.

In a university chemistry lab’s sample heating system, the Motorola MVME-201 acts as a standalone controller: its digital inputs monitor heater overheat switches, digital outputs activate the heater and a status LED, and the parallel port prints test timestamps to a small lab printer. The module’s 0°C–60°C operating range withstands lab temperature fluctuations, while the battery-backed SRAM retains heating schedules during power outages—avoiding lost experiment data. For the lab, the Motorola MVME-201 avoids the $8k cost of upgrading to a modern PLC, as it reliably handles daily heating cycles with <1% annual downtime.

MOTOROLA MVME-201

Related Model Recommendations

Motorola MVME-121: Mid-Entry Controller. Upgrade for Motorola MVME-201 when more I/O (8 vs. 16 channels) or a faster processor (16 MHz MC68000 vs. 8 MHz) is needed (e.g., small manufacturing lines).

Motorola MVME-050: Digital I/O Module. Complements Motorola MVME-201 by adding 16 extra I/O channels (e.g., for expanding sensor/actuator count in warehouse systems).

Motorola MVME-705-1: Serial Communication Module. Adds 8 configurable serial ports to Motorola MVME-201 for systems needing more sensor connectivity (e.g., multiple temperature probes in a greenhouse).

Emerson RSTi-EP CPE100: Modern Replacement. Replaces Motorola MVME-201 in Ethernet migrations; offers similar I/O/communication with Gigabit Ethernet for remote monitoring.

Motorola FLN4234A: Ethernet Gateway. Bridges Motorola MVME-201 (via a VME controller) to cloud platforms; transmits I/O data for lab or small-factory oversight.

Centronics Parallel Cable: Accessory for Motorola MVME-201; extends the parallel port to 3 meters, enabling flexible printer placement in small labs.

Motorola MVME712-101: High-Performance SBC. Upgrade for Motorola MVME-201 when complex processing (e.g., real-time data analysis) is required (e.g., mid-scale manufacturing).

Phoenix Contact 1kΩ Pull-Up Resistors: Accessory for Motorola MVME-201; enables digital outputs to control 12–24 VDC actuators (e.g., small relays in auxiliary systems).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-201, power off the VME chassis and verify compatibility with +5 VDC (1.0 A max; no ±12 VDC needed) to prevent electrical shock. Use an anti-static wristband and mat to protect the module’s MC68000 processor and I/O circuits from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), 22–18 AWG wires (digital I/O), serial/parallel cables, torque wrench (0.5–0.8 N·m for terminals), and a multimeter (to test TTL signal levels). Avoid installing near high-EMI sources (e.g., small fans or power supplies) to prevent serial signal corruption.

Maintenance suggestions: For routine care, inspect Motorola MVME-201’s LEDs monthly—blinking “TX/RX” confirms serial communication, while green “I/O active” LEDs indicate proper sensor/actuator connectivity. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and LED indicators. Every 18 months, replace the SRAM backup battery (3V lithium) to avoid configuration data loss. If the serial port fails, use the module’s hardware reset switch to troubleshoot; replace the module if I/O drivers malfunction. Store a spare EPROM with firmware to minimize downtime during repairs.

Service and Guarantee Commitment

We back Motorola MVME-201 with a 90-day warranty for all refurbished units, covering defects in processing, communication, and digital I/O functionality. Each refurbished Motorola MVME-201 undergoes rigorous testing: 24-hour serial data transfer (9600 bps, zero packet loss), I/O cycling (10,000 toggles per channel), and temperature cycling (0°C–60°C)—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME-201 installation, firmware configuration, and integration with legacy VME modules (e.g., Motorola MVME-050, Motorola MVME-705-1). We offer customized maintenance plans: semi-annual remote health checks (via FLN4234A) and on-site battery replacement services. Our spare parts inventory includes critical components (MC68000 processors, EPROMs) for fast repairs, minimizing downtime for small-scale systems. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME-201 with Emerson’s RSTi-EP gateways, ensuring a seamless transition while retaining legacy peripherals.