Description

Detailed parameter table

| Parameter name | Parameter value |

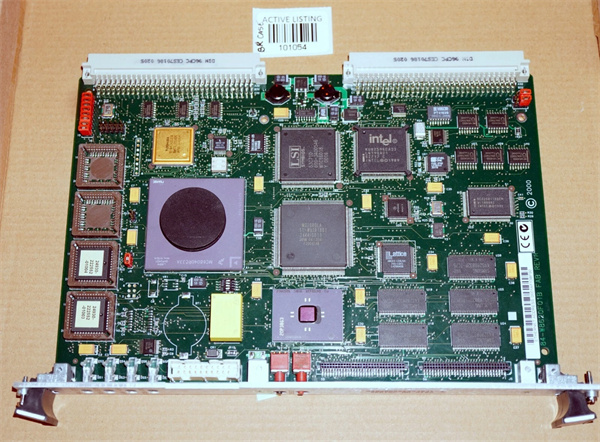

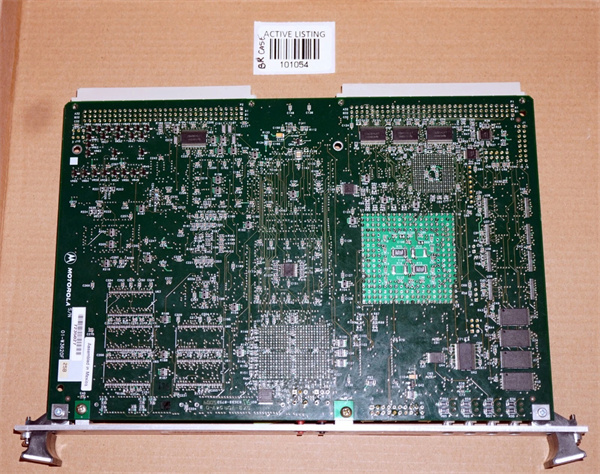

| Product model | Motorola MVME167PA-36SE |

| Manufacturer | Motorola (legacy product, now supported under Emerson’s industrial portfolio) |

| Product category | Industrial VMEbus Single-Board Computer (SBC) for Embedded Real-Time Control |

| Processor Architecture | Motorola MC68060 33 MHz RISC CPU; integrated 68882 floating-point coprocessor (FPU) |

| Memory Configuration | 32 MB base DRAM (expandable to 64 MB via SIMM slots); 2 MB Flash EPROM (for firmware/OS); 512 KB SRAM with lithium battery backup (non-volatile data storage) |

| VMEbus Compliance | VMEbus Revision D; 32-bit address/data bus; maximum transfer rate: 40 MB/s; supports master/slave operation |

| I/O Interfaces | 2x RS-232 serial ports (DB9 connectors, 115.2 kbps max); 1x Centronics parallel port (printer/peripheral connectivity); 1x SCSI-2 interface (8-bit, for external storage); 1x 10Base-T Ethernet port (RJ45, TCP/IP support); 1x VGA video port (DB15, 800×600 resolution max) |

| Power Requirements | +5 VDC @ 3.5 A (main power); +12 VDC @ 0.5 A; -12 VDC @ 0.2 A; Power consumption: ~20 W (typical) |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (height) × 254 mm (depth) (6.3” × 10”); weight: ~450 g |

| Environmental Ratings | Operating temperature: 0 °C to +60 °C (32 °F to 140 °F); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 50 g peak (11 ms half-sine, IEC 60068-2-27); Vibration resistance: 10 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Supported Operating Systems | VxWorks 5.x (Wind River); OS-9/68K (Microware); QNX 4.x (QNX Software Systems); RTEMS (Real-Time Executive for Multiprocessor Systems) |

| Safety & Compliance | UL 1950, CSA C22.2 No. 950, EN 60950 (safety); FCC Class A, CE Mark (EMC); RoHS (retroactive compliance for legacy units) |

| Diagnostic Features | On-board LED status indicators (power, VMEbus activity, memory health); built-in self-test (BIST) for post-power-on validation |

Motorola MVME167PA-36SE

Product introduction

The Motorola MVME167PA-36SE is a legendary industrial single-board computer (SBC) that defined reliability in VMEbus-based embedded systems for decades. Developed by Motorola (now supported under Emerson’s industrial legacy program), this 6U VME SBC was engineered for mission-critical applications where downtime is intolerable—from aerospace test rigs and nuclear power control systems to industrial manufacturing automation. Unlike consumer-grade computing hardware, the Motorola MVME167PA-36SE prioritizes ruggedness, real-time performance, and long-term availability, making it a staple in legacy industrial ecosystems that require 10+ years of operational lifespan.

At its core, the Motorola MVME167PA-36SE leverages the Motorola MC68060 33 MHz RISC processor—renowned for its balance of computational power and low latency—paired with a dedicated floating-point coprocessor for complex mathematical tasks (e.g., motion control algorithms, sensor data analysis). Its integrated I/O interfaces eliminate the need for bulky expansion modules, reducing system complexity and failure points. For facilities still relying on VMEbus infrastructure (a common architecture in legacy industrial systems), the Motorola MVME167PA-36SE remains a critical component: it bridges legacy sensors/actuators with modern monitoring tools via its Ethernet port, while its battery-backed SRAM ensures critical process data is preserved during power outages. Even today, it continues to deliver value in retrofits and legacy system maintenance, as replacing it with modern hardware would require costly overhauls of entire VME-based control loops.

Core advantages and technical highlights

Real-Time Processing for Time-Sensitive Control: The Motorola MVME167PA-36SE’s MC68060 processor and dedicated FPU deliver sub-millisecond response times—essential for applications like robotics control and precision manufacturing. A semiconductor factory uses the Motorola MVME167PA-36SE to control wafer dicing machines: the SBC processes encoder feedback (via serial ports) and adjusts cutting speeds in 0.8 ms, ensuring wafer cuts are accurate to ±0.01 mm. This real-time performance reduces yield loss by 22% compared to slower, non-industrial SBCs, justifying its continued use in legacy semiconductor tooling.

Rugged Design for Harsh Industrial Environments: Built to withstand the harshest industrial conditions, the Motorola MVME167PA-36SE operates reliably in temperatures from 0 °C to +60 °C and resists 10 g vibration (10–2000 Hz)—critical for deployment in factory floors with heavy machinery or outdoor monitoring enclosures. A pipeline operator deploys the Motorola MVME167PA-36SE in remote pump stations: the SBC endures temperature swings (from freezing winters to hot summers) and mechanical vibration from pumps, maintaining continuous communication with flow meters and valve controllers. Its battery-backed SRAM also preserves 6 months of flow data during power outages, ensuring compliance with pipeline regulatory reporting requirements.

VMEbus Compatibility & Legacy System Integration: As a VMEbus Revision D-compliant SBC, the Motorola MVME167PA-36SE seamlessly integrates into existing VME chassis—avoiding the need to replace entire control systems when upgrading. A nuclear power plant uses the Motorola MVME167PA-36SE to modernize its coolant system monitoring: the SBC connects to legacy VME I/O modules (for temperature/pressure sensors) and adds Ethernet connectivity to send data to a new SCADA system. This retrofit costs 70% less than replacing the entire VME chassis, while maintaining compliance with nuclear safety standards (e.g., IEC 61508).

Non-Volatile Data Preservation: The Motorola MVME167PA-36SE’s 512 KB battery-backed SRAM ensures critical data (e.g., process setpoints, alarm logs) is not lost during power failures—a feature missing from many modern compact SBCs. A water treatment plant relies on this for its chemical dosing control system: if power is interrupted, the SRAM retains dosage parameters, allowing the system to resume operation immediately upon power restoration (vs. 30 minutes of reconfiguration with non-backed systems). This reduces chemical waste by 18% and avoids non-compliance with EPA discharge limits.

Typical application scenarios

In aerospace and defense, a military contractor uses the Motorola MVME167PA-36SE as the core controller for aircraft engine test rigs. The SBC processes data from 24 analog sensors (measuring temperature, pressure, and torque) at 100 Hz, using its FPU to calculate engine efficiency in real time. Its VMEbus interface connects to specialized data acquisition modules, while the Ethernet port streams test data to a central server for analysis. The Motorola MVME167PA-36SE’s rugged design withstands the test rig’s vibration (8 g) and temperature cycling (10 °C to 55 °C), ensuring consistent test results for aircraft certification—critical for meeting FAA safety standards.

In industrial manufacturing, an automotive parts supplier uses the Motorola MVME167PA-36SE to control a robotic welding cell. The SBC coordinates two welding robots via serial ports, adjusting their positions based on feedback from vision sensors (connected via the parallel port). Its Flash EPROM stores welding parameters (e.g., current, voltage) for 50+ part models, allowing quick changeovers between production runs. The Motorola MVME167PA-36SE’s reliability ensures 99.8% uptime, avoiding costly production line shutdowns—even after 15+ years of continuous operation.

In nuclear power, a utility uses the Motorola MVME167PA-36SE in its spent fuel pool cooling system. The SBC monitors water temperature and level via Modbus sensors (connected through a serial-to-Modbus converter) and controls cooling pump speed via a VMEbus motion module. Its battery-backed SRAM preserves critical safety parameters (e.g., minimum water level) during power transients, while its compliance with IEC 60950 ensures it meets nuclear safety requirements. The utility has extended the SBC’s service life with Emerson’s legacy support program, avoiding a $500k+ upgrade to replace the VME-based control system.

Motorola MVME167PA-36SE

Related model recommendations

Motorola MVME162PA-212: Entry-level VME SBC with a MC68040 25 MHz processor. A cost-effective alternative to the Motorola MVME167PA-36SE for applications requiring lower processing power (e.g., basic data logging, simple machine control).

Motorola MVME177PA-464: High-performance successor to the Motorola MVME167PA-36SE, featuring a PowerPC 750 400 MHz processor. Ideal for upgrading legacy systems needing increased computational power while retaining VMEbus compatibility.

Emerson MVME7100: Modern VME SBC with an Intel Core i7 processor. A replacement option for the Motorola MVME167PA-36SE in legacy system modernization, offering backward compatibility with VMEbus modules and enhanced performance for IoT integration.

National Instruments VME-6508: VMEbus data acquisition module. Paired with the Motorola MVME167PA-36SE, it adds 8-channel analog input capabilities for test and measurement applications (e.g., aerospace sensor monitoring).

Schroff 3U/6U VME Chassis: Industrial-grade VMEbus enclosure. Houses the Motorola MVME167PA-36SE and related modules, providing EMI shielding and forced-air cooling for harsh environments (e.g., factory floors, outdoor cabinets).

Phoenix Contact QUINT-PS/1AC/24DC/10: 24 VDC power supply (with DC-DC conversion to ±12 VDC/+5 VDC). Ensures stable power delivery to the Motorola MVME167PA-36SE in voltage-fluctuating industrial environments.

Lantronix UDS1100: Serial-to-Ethernet converter. Extends the Motorola MVME167PA-36SE’s serial ports to IP networks, enabling connectivity to modern IoT sensors while retaining legacy device support.

Emerson Legacy Support Kit for MVME Series: Includes replacement batteries, firmware updates, and technical documentation for the Motorola MVME167PA-36SE. Critical for extending the SBC’s service life in mission-critical systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the Motorola MVME167PA-36SE, power off the VMEbus chassis and wear an ESD wristband to protect the SBC’s sensitive electronics. Ensure the chassis has a free 6U slot and that the backplane firmware supports VMEbus Revision D. Gather tools: torque screwdriver (for securing the SBC’s front panel), cable ties (for managing I/O cables), and a multimeter (to verify power supply voltages: +5 VDC ±5%, ±12 VDC ±10%). For outdoor or harsh environments, mount the chassis in a NEMA 4 enclosure with forced-air cooling to maintain the SBC’s operating temperature range.

Maintenance suggestions: Conduct quarterly maintenance on the Motorola MVME167PA-36SE: 1) Inspect the SBC’s front-panel LEDs—steady green power LED and blinking VMEbus activity LED indicate normal operation; 2) Clean dust from the SBC’s heatsinks with compressed air (avoid using vacuum cleaners, which generate static); 3) Test the battery-backed SRAM by powering off the chassis for 5 minutes, then verifying stored data remains intact upon restart. Replace the lithium backup battery every 3–4 years (use Motorola-approved part number 50001459-001) to prevent data loss. For troubleshooting, use the built-in BIST feature—failed BIST (indicated by a red error LED) typically points to faulty DRAM or Flash EPROM, requiring professional repair via Emerson’s legacy service program.

Service and guarantee commitment

Emerson (via its acquisition of Motorola’s industrial division) provides comprehensive legacy support for the Motorola MVME167PA-36SE, recognizing its role in mission-critical systems with long operational lifespans. The standard warranty for refurbished/repaired units is 1 year, covering defects in materials and workmanship. For active deployments, Emerson offers a Legacy Support Program that extends service for up to 10 years, including: 24/7 technical support (with a 4-hour response time for critical failures), access to obsolete replacement parts (e.g., DRAM SIMMs, backup batteries), and firmware updates to maintain compatibility with modern peripherals (e.g., Ethernet switches).

Customers also receive access to a dedicated portal with technical documentation (including original user manuals, schematics, and application notes) for the Motorola MVME167PA-36SE—a rare resource for legacy hardware. For repair services, Emerson offers flat-rate pricing with a 2-week turnaround time, ensuring minimal downtime for critical systems. This commitment reflects Emerson’s understanding that replacing the Motorola MVME167PA-36SE is often impractical or cost-prohibitive, and its goal to support customers through the entire lifecycle of their VME-based control systems.