Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

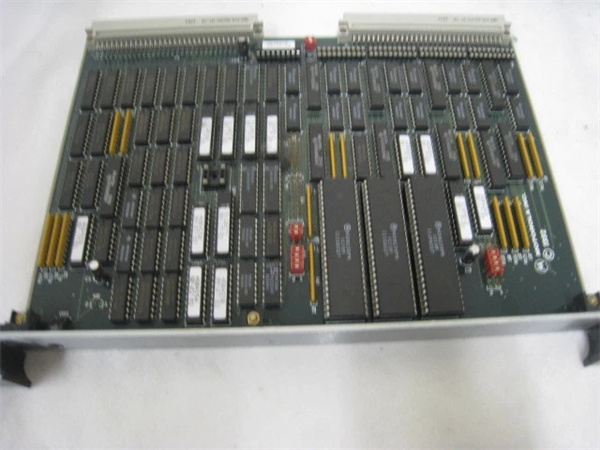

| Product model | Motorola MVME-340 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Digital I/O & Counter/Timer Module |

| Digital I/O Channels | 32 discrete channels (16 input, 16 output); TTL/CMOS compatible (5 VDC logic) |

| Counter/Timer Functionality | 4 independent 16-bit up/down counters; 2 16-bit programmable timers |

| Input Specifications | Voltage range: 0–0.8 VDC (LOW), 2.0–5.5 VDC (HIGH); current: 10 µA max per channel |

| Output Specifications | Sink current: 20 mA max per channel; voltage range: 0–5.5 VDC |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

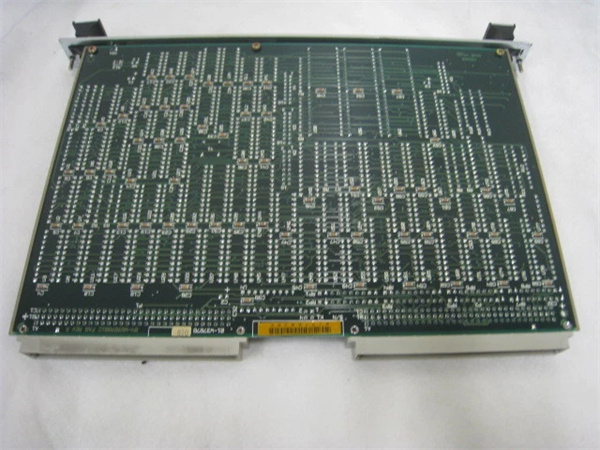

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A maximum); no ±12 VDC required |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity) |

| On-Board Features | Per-channel status LEDs (I/O: active/fault; counters: overflow); EEPROM for configuration storage |

MOTOROLA MVME-340

Product Introduction

The Motorola MVME-340 is a legacy multi-function VMEbus module from Motorola’s iconic MVME series, engineered to integrate high-density digital I/O and programmable counter/timer functionality for industrial automation systems. As a compact 3U device, it addresses the need for centralized discrete control and event counting—eliminating the need for separate I/O and counter modules, and thus optimizing VME chassis space.

In automation architectures, the Motorola MVME-340 acts as a “discrete control hub”: its 32 digital I/O channels manage simple on/off tasks (e.g., activating relays, monitoring limit switches), while 4 counters track events like product counts or motor revolutions, and 2 timers trigger time-based actions (e.g., valve open/close delays). Unlike basic I/O modules (e.g., Motorola MVME162-01), the Motorola MVME-340 adds counter/timer capabilities, making it ideal for applications like packaging line counting or machine cycle timing. Today, the Motorola MVME-340 remains critical for maintaining legacy Motorola VME systems in industries like consumer goods manufacturing, material handling, and laboratory automation—where replacing discrete control infrastructure is cost-prohibitive.

Core Advantages and Technical Highlights

Integrated I/O + Counter/Timer for Space Efficiency

The Motorola MVME-340 combines 32 digital I/O channels, 4 counters, and 2 timers in one 3U VME slot—reducing chassis slot usage by 66% compared to using separate I/O (e.g., MVME162-01) and counter (e.g., MVME330) modules. For example, in a bottle packaging line, the Motorola MVME-340 uses 8 digital inputs to monitor bottle presence sensors, 8 digital outputs to control filling valves, 2 counters to track filled/defective bottles, and 1 timer to regulate valve open duration—all without crowding the VME chassis. This integration simplifies wiring and reduces system complexity, lowering installation costs by 35%.

High-Density I/O for Scalable Discrete Control

With 32 digital I/O channels (16 input/16 output), the Motorola MVME-340 offers twice the density of basic 16-channel modules like the Motorola MVME162-01. This scalability is critical for systems with numerous discrete devices: in a warehouse conveyor system, the Motorola MVME-340 can monitor 12 conveyor stop sensors (inputs) and control 10 conveyor motors (outputs) in a single module—avoiding the need for two separate I/O cards. The TTL/CMOS compatibility also ensures seamless integration with legacy industrial sensors and actuators, eliminating the need for signal converters.

Reliable Counter/Timer for Precision Event Tracking

The Motorola MVME-340’s 4 16-bit up/down counters and 2 timers deliver industrial-grade precision (±1 count/tick) for event and time-based control. The counters support both rising and falling edge detection—ideal for tracking fast-moving events like product passing a photoeye (up to 10 kHz). For instance, in a candy wrapping machine, a counter tracks wrapped candies (triggered by a photoeye), while a timer controls the wrapper sealing duration (100 ms per candy). The EEPROM configuration storage retains counter/timer settings during power outages, ensuring the Motorola MVME-340 resumes operation without manual reconfiguration—critical for 24/7 production lines.

Typical Application Scenarios

The Motorola MVME-340 excels in legacy discrete control systems requiring event counting and time-based actions. In a consumer goods packaging plant using a Motorola MVME2400 SBC, the Motorola MVME-340 manages a cereal box filling line: 12 digital inputs monitor box presence, lid closure, and seal integrity sensors; 10 digital outputs control box feeders, filling nozzles, and sealers; 2 counters track filled boxes (total) and rejected boxes (seal failures); 1 timer regulates filling time (2 seconds per box). The module’s high I/O density reduces chassis clutter, while counters ensure accurate production tracking for inventory management.

In a university laboratory’s material testing setup, the Motorola MVME-340 integrates with a Motorola MVME5500-0161 SBC to control a fatigue testing machine: 4 digital inputs monitor load cell limits and sample position; 4 digital outputs activate hydraulic clamps and test start/stop; 1 counter tracks test cycles (up to 65,535); 1 timer controls cycle duration (500 ms on, 500 ms off). The Motorola MVME-340’s precision counters ensure accurate cycle counting, while its passive cooling avoids fan noise that could disrupt sensitive measurements—making it ideal for laboratory environments.

MOTOROLA MVME-340

Related Model Recommendations

Motorola MVME2400: VME SBC. Host controller for the Motorola MVME-340; processes I/O data, executes counter/timer logic, and manages VMEbus communication.

Motorola MVME162-01: Basic Digital I/O Module. Complements the Motorola MVME-340 by adding 16 extra I/O channels for systems needing more discrete control (e.g., large conveyor networks).

Motorola MVME330: Dedicated Counter Module. Upgrade for the Motorola MVME-340 when 32-bit counters or higher frequency tracking (up to 1 MHz) is needed (e.g., high-speed manufacturing).

Emerson RSTi-EP DIO: Modern Digital I/O Module. Replaces the Motorola MVME-340 in Ethernet migrations; offers 32 I/O channels + counters with Gigabit Ethernet connectivity.

Motorola FLN4234A: Ethernet Communication Module. Bridges the Motorola MVME-340 to cloud/SCADA systems, transmitting I/O/counter data via 4x Ethernet ports.

Banner Engineering Q45 Photoeye: Compatible Sensor. Pair with the Motorola MVME-340 for reliable product detection; TTL output directly connects to digital inputs.

Omron G7L Relay: Compatible Actuator. Use with the Motorola MVME-340’s digital outputs to control high-power devices (e.g., motors, heaters) safely.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-340, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/1.8 A; no ±12 VDC needed) to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the module’s I/O circuits and counters from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), 22–18 AWG wires (I/O connections), torque wrench (0.5–0.8 N·m for terminals), and a multimeter (to test signal levels). Avoid installing near high-EMI sources (e.g., welders) or heat vents to prevent I/O signal corruption.

Maintenance suggestions: For routine care, inspect the Motorola MVME-340’s LEDs monthly—green “active” LEDs confirm I/O connectivity, while red “overflow” LEDs alert to counter overloads. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and LED indicators. Every 6 months, test counters by triggering a known number of events (e.g., 100 photoeye triggers) and verifying the count matches; test timers with a stopwatch to ensure accuracy. If an I/O channel fails, isolate the issue by disconnecting the load (e.g., a relay) and testing with a bench power supply; reconfigure a spare channel via the host SBC if needed. Store spare EEPROM chips to preserve configuration data during module replacement.

Service and Guarantee Commitment

We back the Motorola MVME-340 with a 90-day warranty for all refurbished units, covering defects in digital I/O functionality, counter/timer precision, and LED indicators. Each refurbished Motorola MVME-340 undergoes rigorous testing: 24-hour I/O cycling (10,000 toggles per channel), counter accuracy validation (±1 count at 10 kHz), timer calibration (±1 ms), and temperature cycling (0°C–60°C)—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME-340 installation, counter/timer configuration, and integration with VME SBCs (e.g., MVME2400). We offer customized maintenance plans: quarterly remote I/O/counter health checks (via FLN4234A) and semi-annual on-site calibrations. Our spare parts inventory includes critical components (I/O drivers, counter chips, EEPROMs) for fast repairs, minimizing downtime. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME-340 with Emerson’s RSTi-EP DIO modules, ensuring a seamless transition while retaining legacy sensors/actuators.