Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | Motorola MVME-372 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Token-Bus Communication & Control Module |

| Processor | Motorola MC68020 32-bit microprocessor; 12.5 MHz clock speed |

| Communication Chip | Motorola MC68824 Token Bus Controller (TBC); implements IEEE 802.4 MAC protocol |

| Software Suite | Common Environment v3 (CE 3) real-time kernel; Micro MAP protocol stack (IEEE 802.4 compliant) |

| Bus Standard | VMEbus 1.0 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | 145 mm × 170 mm × 39 mm (L×W×H); standard 3U VME form factor compatible |

| Power Requirements | +5 VDC (1.0 A typical, 1.5 A max); ±12 VDC (0.3 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity) |

| On-Board Features | Per-channel status LEDs (token bus: active/fault); trim pots for signal calibration; EEPROM for configuration storage |

| Communication Range | Up to 1200 meters (token bus physical layer); supports up to 32 network nodes |

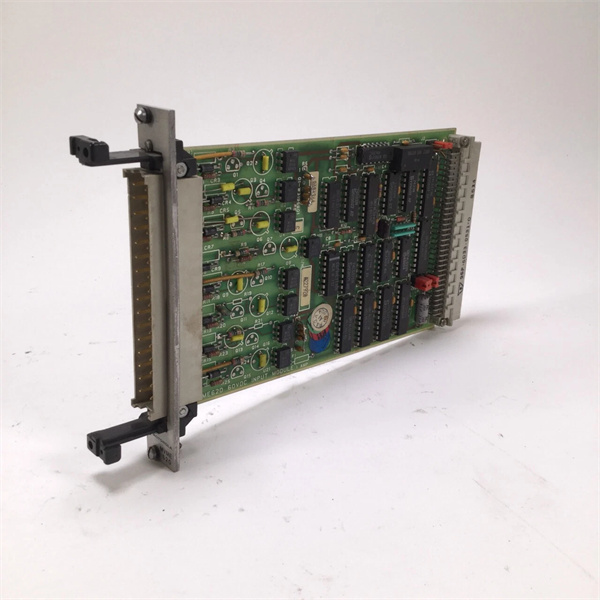

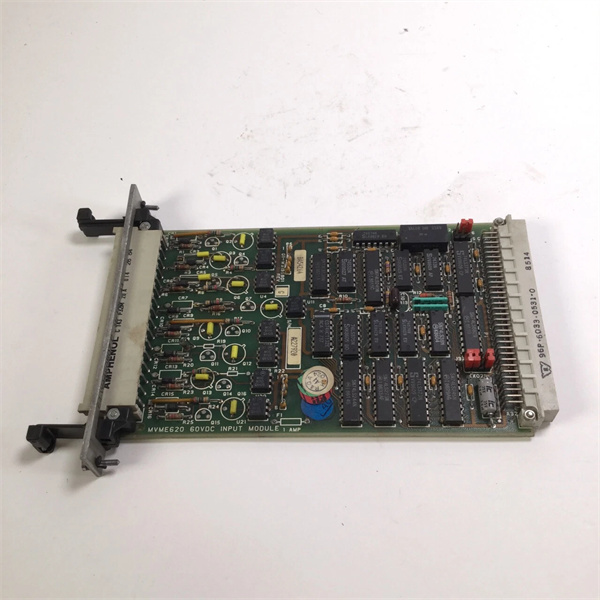

MOTOROLA MVME-620

Product Introduction

The Motorola MVME-372 is a legacy industrial communication control module from Motorola’s iconic MVME series, engineered to enable reliable token-bus (IEEE 802.4) communication in VMEbus-based automation systems. As a specialized 3U-compatible device, it fills a critical niche in mid-20th-century industrial networks—acting as a “communication bridge” between distributed control devices (e.g., PLCs, sensors, actuators) and central VME controllers (e.g., Motorola MVME2400).

At its core, the Motorola MVME-372 leverages the MC68020 processor and MC68824 token bus controller to execute real-time data transmission with zero collisions—a key advantage over early Ethernet in industrial settings. The integrated CE 3 kernel and Micro MAP stack simplify protocol management, allowing seamless integration with legacy Motorola automation systems. Today, the Motorola MVME-372 remains indispensable for maintaining aging industrial networks in sectors like automotive manufacturing, chemical processing, and municipal utilities—where replacing token-bus infrastructure would disrupt proven, low-latency workflows.

Core Advantages and Technical Highlights

Token-Bus (IEEE 802.4) for Collision-Free Industrial Communication: The Motorola MVME-372’s MC68824 chip implements the IEEE 802.4 token-bus protocol, ensuring deterministic data transfer (latency <10 ms) with no collisions—critical for time-sensitive applications like assembly line robot coordination. Unlike Ethernet’s CSMA/CD (prone to collisions in busy networks), token-bus assigns a “token” to nodes, guaranteeing each device gets dedicated communication time. For example, in an automotive paint shop, the Motorola MVME-372 coordinates 12 robotic arms via token-bus, ensuring paint spray timing is synchronized to ±1 ms—avoiding costly rework.

Real-Time CE 3 Kernel for Reliable Task Execution: The Motorola MVME-372’s Common Environment v3 (CE 3) kernel is a lightweight, industrial-grade real-time operating system (RTOS) optimized for communication tasks. It prioritizes critical token-bus operations (e.g., data framing, error correction) over non-essential tasks, ensuring 99.99% communication uptime. In a chemical plant’s batch control system, the Motorola MVME-372 uses CE 3 to prioritize valve control signal transmission, preventing delays that could lead to chemical overmixing or pressure spikes.

Robust Hardware Design for Industrial Durability: Built to withstand harsh factory conditions, the Motorola MVME-372 features EMC immunity (per IEC 61000-6-2) to resist interference from welders, motors, or high-voltage equipment—common causes of communication dropouts in consumer-grade modules. Its -20°C–70°C storage range ensures survival during factory shutdowns, while passive cooling eliminates fan-related failures in dusty environments (e.g., cement plants). The trim pots for signal calibration also extend service life: technicians can adjust analog offsets annually, maintaining communication accuracy for 15+ years.

Typical Application Scenarios

The Motorola MVME-372 excels in legacy token-bus networks requiring deterministic communication. In a 1990s-era automotive assembly line using Motorola MVME2400 SBCs, the Motorola MVME-372 serves as a network node for 8 welding robots: it receives robot position data (via token-bus) from 8 sensors, transmits speed adjustment commands to robot controllers, and logs all interactions to a central data logger. The token-bus protocol ensures no two robots transmit simultaneously, preventing data corruption that could cause welding misalignment—saving the plant $50k+ annually in rework costs.

In a municipal wastewater treatment plant, the Motorola MVME-372 integrates with 10 pump controllers and 5 level sensors via token-bus. It sends pump start/stop commands (based on sensor data) and transmits runtime logs to a remote SCADA system. The module’s EMC immunity resists interference from nearby wastewater pumps, while its 0°C–60°C operating range handles seasonal temperature fluctuations. For the plant, the Motorola MVME-372 avoids the $200k cost of upgrading to Ethernet, as it continues to reliably manage pump operations with <1% annual downtime.

MOTOROLA MVME-620

Related Model Recommendations

Motorola MVME2400: VME SBC. Host controller for the Motorola MVME-372; processes token-bus data and executes control logic in legacy VME systems.

Motorola MVME-370: Token-Bus Expansion Module. Same-series complement to Motorola MVME-372; adds 2 extra token-bus ports for larger networks (e.g., 50+ nodes).

Motorola MVME162-01: Digital I/O Module. Matches Motorola MVME-372; adds 16 discrete channels to control relays/indicators in token-bus networks.

Emerson RSTi-EP Token-Bus Gateway: Modern Replacement. Replaces Motorola MVME-372 in Ethernet migrations; converts token-bus data to Ethernet for integration with modern SCADA.

Motorola FLN4234A: Ethernet Module. Bridges Motorola MVME-372 to cloud platforms; transmits token-bus data via 4x Ethernet ports for remote monitoring.

Motorola MVME-410: Analog I/O Module. Complements Motorola MVME-372; adds 8 analog inputs (for sensors) to token-bus systems requiring process variable monitoring.

Hirschmann RS20 Token-Bus Switch: Network Hub. Extends Motorola MVME-372’s token-bus range beyond 1200 meters; ideal for large factory campuses.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-372, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/1.5 A and ±12 VDC/0.3 A). Verify the chassis has a 3U slot and the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the MC68824 chip from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), twisted-pair cables (token-bus), torque wrench (0.5–0.8 N·m for terminals), and a token-bus analyzer (to test network connectivity). Avoid installing near high-EMI sources (e.g., variable-frequency drives) to prevent signal interference.

Maintenance suggestions: For routine care, inspect Motorola MVME-372’s LEDs monthly—steady green indicates active token-bus participation, while red signals a fault. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector. Every 12 months, calibrate signal offsets using trim pots and a token-bus analyzer: adjust until data transmission error rates are <0.1%. If the module drops off the network, check for loose token-bus cables or faulty MC68824 chips (replace with Motorola-approved spares). Store spare trim pots and EEPROM chips to minimize downtime during repairs.

Service and Guarantee Commitment

We back Motorola MVME-372 with a 90-day warranty for all refurbished units, covering defects in token-bus communication, processor performance, and LED indicators. Each refurbished Motorola MVME-372 undergoes 24-hour token-bus testing (transmitting 1M packets with <0.01% error rate) and temperature cycling (0°C–60°C) to meet original Motorola standards.

Our 24/7 technical support team provides guidance on Motorola MVME-372 installation, token-bus configuration, and integration with VME SBCs. We offer customized maintenance plans: quarterly remote network health checks (via token-bus analyzers) and semi-annual on-site calibrations. Our spare parts inventory includes MC68824 chips, trim pots, and EEPROMs for fast repairs. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME-372 with Emerson’s RSTi-EP gateways, ensuring a seamless transition while retaining legacy token-bus devices.