Description

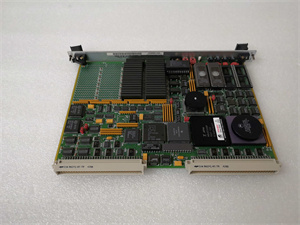

Motorola MVME147SRF Product Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

MVME147SRF

|

|

Manufacturer

|

Motorola

|

|

Product category

|

Embedded single – board processor module

|

|

Processor

|

MC68030 microprocessor, clock speeds from 16MHz to 33.33MHz available

|

|

Floating – point coprocessor

|

Optional MC68882

|

|

Memory

|

Shared DRAM, 4MB – 32MB selectable, no parity check on MVME147SRF

|

|

Battery – backed CMOS RAM

|

2K x 8

|

|

Serial ports

|

4, with RS – 232C buffers

|

|

SCSI bus interface

|

Small Computer System Interface with DMA channel

|

|

Timing clock/calendar

|

Battery – backed

|

|

ROM/PROM/EPROM sockets

|

4, 16 – bit wide

|

|

VME bus interface

|

Supports A32/D32, A24/D16, has VME bus master, requester functions, includes system controller functions and interrupter

|

|

Status indicators

|

SCON, DUAL, FAIL, and STATUS

|

|

Switches

|

Reset and abort switches

|

|

Printer port

|

Centronics printer port

|

|

Tick timers

|

Two 16 – bit tick timers for periodic interrupts

|

|

Watchdog timer

|

Present

|

|

Ethernet transceiver interface

|

Absent (characteristic of MVME147SRF model)

|

|

Operating temperature range

|

– 20°C to 70°C

|

|

Humidity range

|

5% – 95% (non – condensing)

|

|

Shock and vibration resistance

|

Complies with MIL – STD – 810 standard

|

|

Form factor

|

Modular

|

|

Operating voltage

|

240V

|

MVME147SRF

Product introduction

The Motorola MVME147SRF is an advanced embedded single – board processor module developed by Motorola, a globally renowned leader in industrial technology. It plays a pivotal role in a wide range of industrial control and automation systems, facilitating seamless data processing and system control.

Powered by the MC68030 microprocessor, which offers a choice of clock speeds between 16MHz and 33.33MHz, the MVME147SRF is well – equipped to handle diverse computational tasks. The optional MC68882 floating – point coprocessor further bolsters its capacity for complex calculations, making it suitable for applications demanding high – precision numerical processing. With a flexible memory configuration ranging from 4MB to 32MB of shared DRAM (without parity check in this specific MVME147SRF model), it can efficiently store and manage data for real – time operations.

The module comes with an array of interfaces. The four RS – 232C buffered serial ports, SCSI bus interface with DMA channels, and Centronics printer port enable easy connection to various external devices. Features like the two 16 – bit tick timers for periodic interrupts, watchdog timer, and the VME bus interface (supporting A32/D32 and A24/D16) contribute to its versatility in industrial control setups. The Motorola MVME147SRF is engineered to be a reliable and high – performance solution for industrial applications that require robust processing capabilities.

Core advantages and technical highlights

High – performance processing

The MVME147SRF‘s MC68030 microprocessor, combined with the optional MC68882 floating – point coprocessor, offers remarkable processing prowess. In industrial automation scenarios where real – time data analysis and control decisions are crucial, the module can swiftly execute complex algorithms. For instance, in a manufacturing plant’s quality control system, it can process sensor data in real – time to promptly detect product defects. The ability to select different clock speeds allows users to optimize performance according to specific application requirements, whether for basic control tasks or more data – intensive operations.

Abundant interfaces and expandability

With multiple interfaces such as four serial ports, an SCSI bus interface, and a printer port, the MVME147SRF can be effortlessly integrated into diverse industrial setups. The SCSI interface, with its DMA channels, enables high – speed data transfer to and from storage devices like hard drives, which is essential for applications needing quick access to large amounts of data. The availability of four ROM/PROM/EPROM sockets provides additional room for expansion, for storing program code or data. In an industrial control system, this expandability can be harnessed to add new functionality or update existing software without significant hardware modifications.

Reliable industrial – grade design

Designed to function in harsh industrial environments, the MVME147SRF has a broad working temperature range from – 20°C to 70°C and can endure humidity levels between 5% and 95% (non – condensing). Its resistance to shock and vibration, in line with the MIL – STD – 810 standard, ensures reliable operation even in applications where the equipment is subject to physical stress, such as in mobile industrial machinery or plants with heavy equipment operation. Features like a watchdog timer and status indicators further enhance its reliability by providing self – monitoring and fault – detection capabilities.

MVME147SRF

Typical application scenarios

Industrial automation

In industrial automation, the Motorola MVME147SRF serves as a crucial component. It can be deployed as a central controller in Programmable Logic Controller (PLC) and Distributed Control System (DCS) setups. For example, in an automotive assembly line, the MVME147SRF can receive data from sensors placed along the production line. These sensors may detect the position of car parts, the status of robotic arms, or the speed of conveyor belts. The module then processes this data and sends out control signals to actuators, motors, and other devices to ensure smooth and efficient production. It can also communicate with other components in the automation system, such as Human – Machine Interfaces (HMIs), to provide operators with real – time information about the production process.

Communication equipment control

In the telecommunications industry, the MVME147SRF can be utilized in base station controllers. It can manage the intricate operations of wireless signal transmission and switching. For instance, it can process data from multiple antennas, adjust signal strength and frequency based on network conditions, and control the handover of connections between different cells. The module’s high – speed processing capabilities and reliable performance are vital in ensuring seamless communication services for mobile users.

Medical equipment

In medical imaging devices like CT and MRI scanners, the MVME147SRF can be involved in the image acquisition and processing phases. It can receive data from sensors within the scanner and process this data to reconstruct high – quality medical images. The module’s capacity to handle complex calculations rapidly, due to the optional floating – point coprocessor, is essential for accurate image processing. Additionally, its reliable operation in a medical environment, where equipment downtime can have severe consequences, makes it a suitable choice for such critical applications.

Related model recommendations

MVME147S

Similar to the MVME147SRF, the MVME147S has shared DRAM with parity check (unlike the SRF model). It also features an Ethernet transceiver interface, which the MVME147SRF lacks. This makes the MVME147S more suitable for applications that require Ethernet – based communication, such as in network – connected industrial control systems where real – time data sharing over an Ethernet network is crucial.

MVME147 – 013A

This model offers an upgrade in terms of memory capacity, as it can support up to 32MB of memory. If an application using the MVME147SRF outgrows its current memory requirements, the MVME147 – 013A can be a suitable replacement. It provides enhanced data storage and processing capabilities, making it ideal for applications that deal with large amounts of data, such as in high – resolution image processing in the medical or industrial inspection fields.

MVME147SB – 1

This model might have specific hardware or software optimizations for certain applications. It could be designed to work better in a particular industrial environment or for a specific type of control task. For example, it may have improved power management features, making it more suitable for applications where power consumption is a concern, like in remote industrial monitoring stations powered by batteries or solar panels.

MVME162 – 012

While it has a different processor (MPC7457 running at 1 GHz) compared to the MVME147SRF‘s MC68030, the MVME162 – 012 offers high – performance processing in a different architecture. It may be considered as an alternative for applications that require extremely high – speed processing and have different interface or software compatibility requirements. In applications such as high – speed data analytics in large – scale industrial plants, the MVME162 – 012’s capabilities could be more suitable.

MVME5100

Part of the MVME3100 series, the MVME5100 offers features like an integrated MPC8540 SoC processor, DDR memory, and support for advanced interfaces such as Gigabit Ethernet, PCI – X, USB, and SATA. If an application using the MVME147SRF needs to be upgraded to a more modern and feature – rich system, the MVME5100 can be a good choice. It provides a significant performance boost and better connectivity options, which are beneficial for applications in emerging industrial technologies like the Internet of Things (IoT) – enabled industrial control systems.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Motorola MVME147SRF, ensure that the installation environment meets the module’s requirements. The ambient temperature should be within the range of – 20°C to 70°C, and the humidity level should be between 5% and 95% (non – condensing). Use appropriate tools such as screwdrivers and anti – static wrist straps to prevent electrostatic discharge, which can damage the sensitive components of the module. When installing the module in a VMEbus system, make sure the VMEbus backplane is properly configured and functioning. Follow the wiring diagram carefully when connecting the power supply, ensuring that the 240V power connection is correct and secure. Also, take note of the proper orientation of the module when inserting it into the VMEbus slot to avoid incorrect installation.

Maintenance suggestions

Regularly inspect the MVME147SRF for any signs of physical damage, such as cracks on the circuit board or loose connectors. Use a clean, dry, lint – free cloth to gently clean the module to remove dust, as dust accumulation can affect its performance, especially in environments with high – dust levels. Periodically test the functionality of the module by running diagnostic software. Check the operation of the serial ports, SCSI interface, and other components. If any issues are detected, start by checking the wiring and connections. In case of a malfunction, consult the Motorola technical documentation or contact their support team for troubleshooting advice. When replacing parts, always use genuine Motorola replacement parts to ensure compatibility and maintain the high – quality performance of the module. Keep a record of maintenance activities and any issues encountered for future reference.

Service and guarantee commitment

Motorola stands firmly behind the Motorola MVME147SRF. All products undergo rigorous quality control procedures during manufacturing to meet international standards. Motorola offers a competitive warranty period, covering manufacturing defects. In case of any issues during the warranty period, Motorola’s global technical support team is readily available. They can provide detailed guidance on installation, efficient troubleshooting, and maintenance advice. Motorola also invests in continuous research and development to improve the performance of the MVME147SRF and may release software updates (if applicable) to enhance functionality and compatibility. The company provides comprehensive documentation, including user manuals and technical guides, to assist users in making the most of the MVME147SRF. This reflects Motorola’s confidence in the quality of the product and its dedication to customer satisfaction in the industrial control domain.