Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

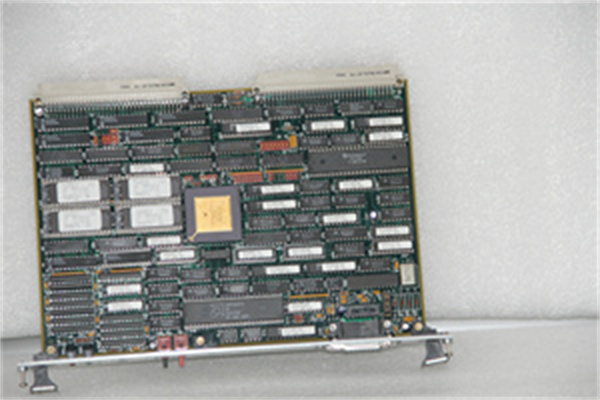

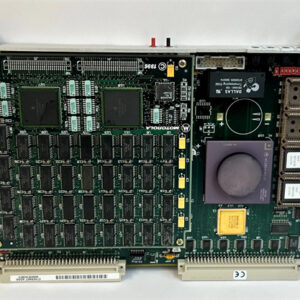

| Product Model | Motorola MVME 374-1 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Single Board Computer |

| Processor | Motorola 68020 (Some sources also mention PowerPC 603e in different variants) |

| Clock Speed | 16 MHz (for 68020 variant); 66 MHz (if PowerPC 603e) |

| Memory | 4 MB RAM (for 68020 variant); 64 MB SDRAM (if PowerPC 603e) |

| Storage | 80 MB hard disk (for 68020 variant); 4 GB CompactFlash (if PowerPC 603e) |

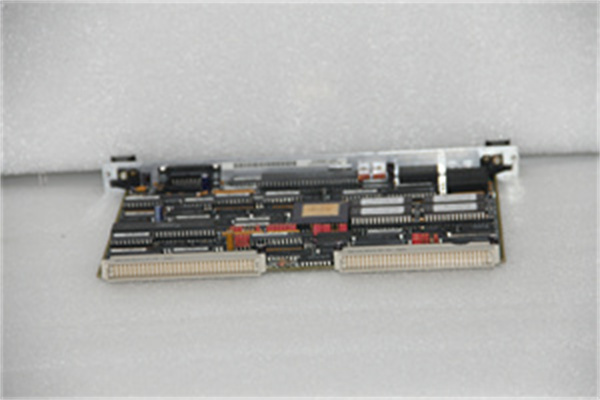

| Expansion Slots | 1 VME bus slot |

| Input/Output Interfaces | 2x RS-232, 2x RS-422, 1x parallel port (IEEE 1284 compliant, bidirectional in some setups); 2x Ethernet (if PowerPC 603e variant), 1x USB (if PowerPC 603e variant), 1x VGA (if PowerPC 603e variant) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 16-bit address/data bus; can operate in master or slave mode; supports VMEbus interrupts (multiple levels) |

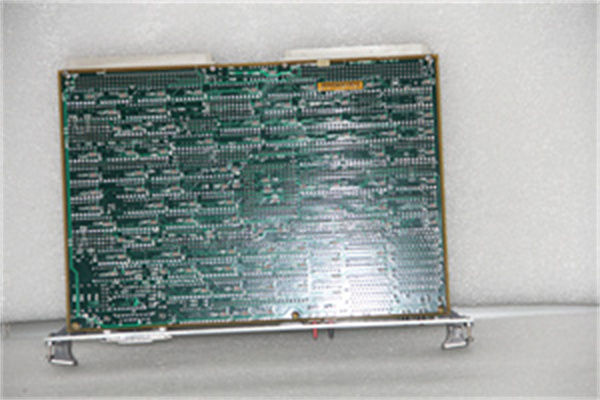

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (±5%), with some variants having an input power range of 89 – 280 VAC; power consumption: 50W typical |

| Operating Temperature Range | -40°C – +85°C (wide industrial environmental tolerance) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; EIA/TIA-232/422; IEEE 1284; CE, FCC, UL, RoHS; IEC 61000-6-2 (industrial EMC immunity) |

| Compatibility | Compatible with a wide range of VMEbus – based systems, including other Motorola VME modules such as communication (e.g., MVME707), I/O (e.g., MVME – 162-020A), and power modules (e.g., FAB 0340-1049) |

| On – Board Features | Abort and reset buttons; status LEDs; some variants may have additional features like serial port surge protection, parallel port overvoltage protection, and EEPROM for configuration storage |

MOTOROLA MVME 374-1

Product Introduction

The Motorola MVME 374 – 1 is a high – performance VMEbus single board computer meticulously designed for industrial control systems. Its versatility and robustness make it a cornerstone for applications where reliable and efficient data processing is non – negotiable. With a modular design that adheres to the VMEbus standard, it seamlessly integrates with other components within a VME – based system, whether it’s for data acquisition, control logic execution, or communication management.

The MVME 374 – 1 comes in different processor variants. The Motorola 68020 – based version offers a solid foundation for legacy industrial systems that require compatibility with existing software and hardware ecosystems. On the other hand, the PowerPC 603e – equipped variant provides a performance boost, suitable for more demanding applications that need higher computational power, such as real – time data analytics in industrial automation.

Core Advantages and Technical Highlights

High – Performance Processing

The MVME 374 – 1, especially the PowerPC 603e variant with its 66 MHz clock speed, offers significant computational muscle. It can handle complex control algorithms, real – time data processing, and multitasking operations with ease. For example, in a large – scale manufacturing plant, it can simultaneously process sensor data from hundreds of devices, execute control commands for machinery, and communicate with other parts of the control system, all while maintaining high – speed data transfer rates. Even the Motorola 68020 variant, with its 16 MHz clock speed, provides reliable performance for less resource – intensive industrial applications.

Multiple Connectivity Options

With a plethora of input/output interfaces, the MVME 374 – 1 ensures seamless connectivity. The inclusion of RS – 232 and RS – 422 serial ports allows for communication with a wide range of legacy devices, such as barcode scanners, old – fashioned HMIs, and industrial sensors. The parallel port, compliant with IEEE 1284, enables high – speed data transfer to peripheral equipment like industrial printers and data loggers. In the case of the PowerPC 603e variant, the addition of Ethernet, USB, and VGA interfaces further expands its capabilities. Ethernet allows for network – based communication, facilitating connection to remote servers, other industrial nodes, or even the cloud for data storage and remote monitoring. The USB interface can be used to connect external devices like flash drives for data backup or input devices for system configuration. The VGA interface is handy for applications that require local visual monitoring, such as in control rooms where operators need to view system status or diagnostic information.

Robust Design for Harsh Environments

Built to withstand the harshest industrial conditions, the MVME 374 – 1 has an operating temperature range of – 40°C to + 85°C. This makes it suitable for use in outdoor industrial setups, such as oil and gas pipelines in frigid climates or in hot and dusty factory floors. The module is constructed with durable materials and has undergone rigorous testing to ensure it can endure vibrations, shocks, and electrical interference commonly found in industrial environments. Its power supply design is also robust, with some variants capable of handling a wide input voltage range, ensuring stable operation even in areas with inconsistent power supplies.

Energy – Efficient Operation

Despite its high – performance capabilities, the MVME 374 – 1 is designed to be energy – efficient, consuming only 50W typically. This not only helps in reducing operational costs but also makes it suitable for applications where power consumption needs to be minimized, such as in remote industrial monitoring stations that rely on limited power sources like solar panels or battery banks.

Typical Application Scenarios

Industrial Automation in Manufacturing Plants

In a manufacturing plant, the MVME 374 – 1 can act as the central control unit. It uses its Ethernet interface to connect to the plant’s network, receiving production schedules and sending back real – time production data. The RS – 422 ports can be used to communicate with remote sensors located on the production line, gathering data on product quality, machine performance, and environmental conditions. The parallel port is used to send high – volume data, such as production labels or quality control reports, to industrial printers. The PowerPC 603e variant’s high – performance processing capabilities can handle complex control algorithms, ensuring smooth operation of automated machinery, while the Motorola 68020 variant can still manage basic control tasks in less complex production lines.

Remote Monitoring in Oil and Gas Pipelines

For oil and gas pipelines, the MVME 374 – 1 is deployed in remote monitoring stations. Its wide operating temperature range allows it to function in extreme weather conditions. The RS – 232 and RS – 422 ports are used to connect to various sensors along the pipeline, such as pressure sensors, temperature sensors, and leak detectors. The data collected is then transmitted via the Ethernet interface to a central control center, where operators can monitor the pipeline’s status in real – time. In case of any issues, the MVME 374 – 1 can execute pre – programmed control commands, such as shutting off valves or activating alarms.

Smart Grid Management

In a smart grid system, the MVME 374 – 1 can be used for data acquisition and control. It connects to smart meters and other grid – connected devices via its serial and Ethernet interfaces. The module processes the data received, such as power consumption, voltage levels, and grid stability metrics. Based on this data, it can execute control commands to balance the grid, adjust power distribution, and ensure efficient energy usage. The high – performance processing of the PowerPC 603e variant is beneficial for handling the large volume of data generated in a smart grid, while the energy – efficient design helps in reducing power consumption in grid – connected devices.

MOTOROLA MVME 374-1

Related Model Recommendations

Motorola MVME5500: VME SBC. Can be used in tandem with MVME 374 – 1 for more complex control systems. It can offload some of the more resource – intensive tasks, such as complex data processing or high – level control logic, allowing the MVME 374 – 1 to focus on its core functions like device connectivity and basic control operations.

Motorola FAB 0340 – 1049: Power supply module. Provides stable power to the MVME 374 – 1, ensuring reliable operation. Its power output characteristics are well – matched to the requirements of the MVME 374 – 1, guaranteeing stable voltage supply even under varying load conditions.

Motorola MVME – 162 – 020A: Advanced basic digital I/O module. Can be integrated with the MVME 374 – 1 to expand its I/O capabilities. In applications where more discrete control is needed, such as controlling multiple actuators or monitoring a large number of sensors, the MVME – 162 – 020A can be used in combination with the MVME 374 – 1 to meet the I/O requirements.

Belkin IEEE 1284 Parallel Cable: Compatible parallel cable. Useful for extending the parallel port of the MVME 374 – 1, allowing for flexible placement of industrial printers or data loggers away from the VME chassis. This is especially useful in large industrial setups where the physical layout may require longer cable runs.

Emerson RSTi – EP Serial/Ethernet Gateway: For systems migrating to Ethernet – based communication, this gateway can be used with the MVME 374 – 1. It can bridge the gap between the MVME 374 – 1’s serial interfaces and an Ethernet network, enabling seamless integration of legacy serial – based devices into a modern Ethernet – based control system.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the MVME 374 – 1, power off the VME chassis and disconnect all power supplies to avoid electrical hazards. Ensure that the VME chassis has an available 3U slot and that the VME backplane is compatible with the 16 – bit address/data bus of the MVME 374 – 1. Use an anti – static wristband and mat to protect the sensitive components of the module from electrostatic discharge (ESD). Gather the necessary tools, including a Phillips – head screwdriver for chassis mounting, appropriate cables for connecting to external devices (twisted – pair cables for serial connections, IEEE 1284 parallel cable for parallel connections), a torque wrench (0.5 – 0.8 N·m for terminal connections), and a multimeter to test signal levels. Avoid installing the module near high – EMI sources, such as large motors or variable – frequency drives, and heat sources, like power supplies, to prevent signal interference and thermal damage.

Commissioning and Maintenance

For commissioning, insert the MVME 374 – 1 into the VME slot and secure it firmly. Connect the serial devices to the appropriate RS – 232 or RS – 422 ports, following the correct wiring standards (TX/RX/GND for RS – 232; A/B/GND for RS – 422). Connect the parallel port to peripheral equipment, such as a printer, using an IEEE 1284 cable. In the case of the PowerPC 603e variant, connect Ethernet, USB, and VGA devices as required. Power on the system and check the status LEDs on the MVME 374 – 1. The power LED should indicate that the module is receiving power. Serial port TX/RX LEDs should blink when data is being transmitted or received. The parallel port ready LED should be lit when the peripheral is properly connected. Use the appropriate software on a connected host system to configure the module’s settings, such as serial baud rate, parity, and parallel transfer mode. Test the communication by sending test data to connected devices and verifying the receipt of data.

For maintenance, inspect the wiring connections regularly, tightening any loose terminals and replacing damaged cables. Clean the module quarterly using compressed air (low pressure) to remove dust from the VME connector and other components. Check the integrity of the serial port surge protection (if available) semi – annually using an ESD simulator. If there are issues with the parallel port, check for bent pins or incorrect peripheral settings. In case of problems with the Ethernet, USB, or VGA interfaces (for the PowerPC 603e variant), ensure that the drivers are up – to – date and that the network or device settings are correct. When upgrading the module, make sure to back up any important configuration data and replicate the settings on the new module to avoid disruptions to the connected systems.

Service and Guarantee Commitment

Although the Motorola MVME 374 – 1 is obsolete, we offer a 90 – day warranty on all refurbished units. This warranty covers defects in processing performance, connectivity functionality (serial, parallel, Ethernet, USB, VGA as applicable), and any on – board features such as status LEDs. Each refurbished module undergoes comprehensive testing, including 24 – hour continuous operation to ensure stable performance, communication tests across all interfaces to verify data transfer accuracy, and checks for any hardware – related issues.

Our technical support team is available 24/7 to provide assistance with installation, configuration, and troubleshooting. We offer customized maintenance plans, which may include quarterly remote performance checks, semi – annual on – site inspections, and software updates (where applicable). Our spare parts inventory includes critical components such as processors, memory modules, and interface controllers, ensuring fast repairs and minimizing downtime for systems using the MVME 374 – 1.

For users looking to modernize their systems, we provide free consultation on alternative solutions, such as migrating to more modern Ethernet – based single board computers or industrial controllers, while still leveraging the existing infrastructure and software as much as possible.