Description

Detailed Parameter Table

**

| Parameter Name | Parameter Value |

| Product model | Motorola MVME – 605 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | Industrial Control Module (PowerPC – based) |

| Processor | Motorola MPC860T PowerPC processor; up to 706 MHz main frequency |

| Memory Configuration | 280 KB application runtime memory; 630 KB non – volatile memory (for application objects, text, and bitmaps); 295 KB communication additional flash memory |

| Communication Ports | Remote I/O (RIO); RS232 (for printer connection); Ethernet (for network connectivity, though not specified in all sources, common for PowerPC – based industrial modules) |

| Input Voltage Range | 35 – 269 V AC, 48 – 67 Hz |

| Physical Dimensions | Shipping dimensions: 380 x 350x 20mm; Module weight: 1.8 kg; Shipping weight: 3.8 lbs |

| Display Area | 125 x 55 mm (4.54 x 3.4 in.); Display type: Green; Touchscreen: 180 touch cells with 1.5 million actuation presses, 120 * 350 resolution |

| Keypad Function Keys | 12 function keys (F1 … F10) |

| Power Consumption | TDP around 38W (approximate value based on processor and module operation) |

| Product Life Cycle Status | Discontinued / Obsolete |

| Expansion Capabilities | Supports connection with other modules to form a complete control system; multiple hardware interfaces and expansion slots for external device connection |

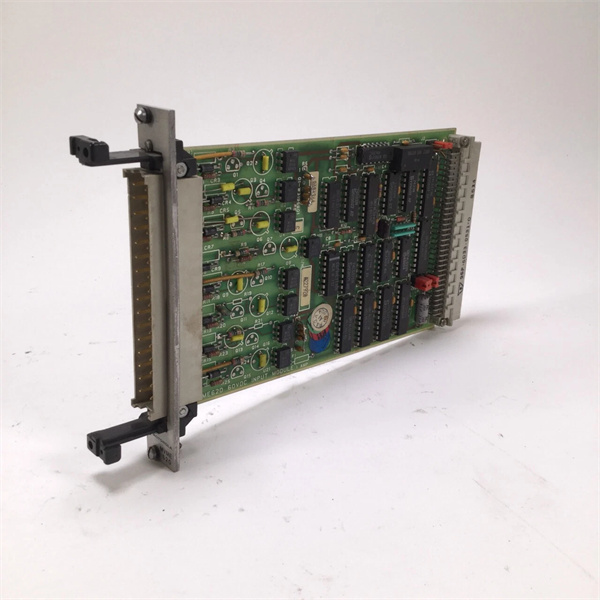

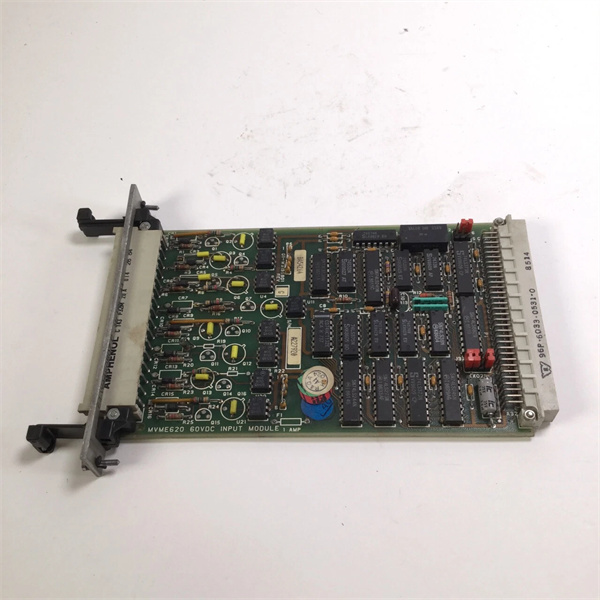

MOTOROLA MVME-620

Product Introduction

The Motorola MVME – 605 is a remarkable industrial control module that was part of Motorola’s innovative lineup. Built on the robust PowerPC architecture, it houses the Motorola MPC860T processor, which enables it to deliver high – performance computing capabilities for industrial applications. This module was designed to meet the demanding requirements of industrial control scenarios, providing a reliable and efficient solution for various operations.

In the industrial control field, the Motorola MVME – 605 serves as a central hub. Its multiple communication ports, such as Remote I/O (RIO) and RS232, allow for seamless connection with a wide range of external devices. For example, the RS232 port can be used to connect to printers for logging important data, while the RIO port enables communication with other industrial components in the network. The inclusion of an Ethernet port (common in PowerPC – based industrial modules) further extends its connectivity, facilitating network – based data transfer and control. With its diverse memory configuration, it can store and execute applications effectively, manage non – volatile data, and handle communication – related data storage.

Core Advantages and Technical Highlights

High – Performance Processing

The Motorola MVME – 605’s Motorola MPC860T processor, running at a main frequency of up to 706 MHz, endows it with strong data processing capabilities. This high – speed processing power allows it to handle complex industrial control algorithms and real – time data analysis with ease. In industrial automation setups, it can quickly process sensor data, make rapid control decisions, and execute commands, ensuring smooth and efficient operation of the overall system. For instance, in a manufacturing plant, it can analyze the data from multiple sensors on the production line in real – time and adjust the operation of machinery accordingly to optimize production efficiency.

Low Power Consumption with Advanced Power Management

Employing advanced power management technology, the Motorola MVME – 605 achieves low power consumption. This not only helps in reducing energy costs in industrial settings but also makes it suitable for applications where power efficiency is crucial, such as in remote or battery – powered industrial monitoring systems. Despite its high – performance capabilities, the module manages to keep power consumption at a reasonable level, with an approximate TDP of 38W. This balance between performance and power consumption is a significant advantage in the industrial control landscape.

High Integration and Scalability

This module is highly integrated, featuring a variety of hardware interfaces and expansion slots. These interfaces and slots make it easy to connect with external devices and expand its functionality. For example, it can be integrated with additional input/output modules, communication modules, or storage devices. This scalability allows the Motorola MVME – 605 to be customized according to the specific needs of different industrial applications. In a large – scale industrial control system, it can be combined with other modules to form a comprehensive control solution, adapting to the evolving requirements of the industrial process.

Industrial – Grade Reliability

Built with high – quality industrial components and manufacturing processes, the Motorola MVME – 605 offers high reliability and stability. It can withstand harsh industrial environments, including high temperatures, vibrations, and electrical interference. In industrial settings such as factories, power plants, or mining operations, where the operating conditions can be challenging, the Motorola MVME – 605 can continue to operate reliably, ensuring uninterrupted control and monitoring of industrial processes.

Typical Application Scenarios

The Motorola MVME – 605 has been widely used in various industrial control fields. In industrial automation, it can be found at the heart of control systems in manufacturing plants. It controls the operation of conveyor belts, robotic arms, and other machinery, ensuring coordinated and efficient production. For example, it can receive signals from sensors that detect the position of products on the conveyor belt and then control the movement of robotic arms to pick and place the products accurately.

In the energy sector, such as in power plants, the Motorola MVME – 605 is used for monitoring and controlling power generation equipment. It can collect data from sensors on generators, turbines, and other power – related machinery, analyze the data, and make adjustments to optimize power generation efficiency and ensure stable power supply.

It also has applications in the transportation industry, specifically in intelligent transportation systems. For example, it can be used in traffic control centers to process data from traffic sensors, cameras, and other devices. Based on this data, it can control traffic signals, manage vehicle flow, and provide real – time traffic information to drivers, contributing to smoother traffic flow and reduced congestion.

MOTOROLA MVME-620

Related Model Recommendations

Motorola MVME – 620: This model, like the Motorola MVME – 605, is also an industrial control module. It offers additional communication interfaces such as parallel ports in addition to serial ports. It can be used in scenarios where more diverse peripheral connectivity is required, complementing the Motorola MVME – 605 in systems that need to connect to a wider range of devices, like industrial printers with parallel interfaces.

Motorola MVME – 701A: Focusing more on serial communication and digital I/O, the Motorola MVME – 701A can be used in conjunction with the Motorola MVME – 605 in systems that require extensive serial data handling and discrete digital control. For example, in a system where the Motorola MVME – 605 is handling overall system management, the Motorola MVME – 701A can be dedicated to handling serial communication with remote sensors and controlling digital outputs for actuators.

Motorola MVME – 702: This module provides Winchester cable termination logic and additional serial channels. In industrial setups where legacy storage connectivity (using Winchester cables) and more serial communication channels are needed, the Motorola MVME – 702 can be added to a system already using the Motorola MVME – 605 to enhance its functionality in data storage and serial – based communication.

Motorola MVME335: The Motorola MVME335 adds multi – protocol support, such as CAN bus support. In applications where there is a need for communication with CAN – bus – enabled devices, like in automotive or industrial robot control systems, it can be integrated with the Motorola MVME – 605 to expand the communication capabilities of the overall system.

Emerson RSTi – EP Series: As a modern alternative, the Emerson RSTi – EP series can be considered for upgrading systems that currently use the Motorola MVME – 605. These modern modules offer advanced features such as Ethernet – based communication, higher processing power, and enhanced I/O capabilities, while still maintaining compatibility with some of the legacy systems and devices that the Motorola MVME – 605 was connected to.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Motorola MVME – 605, ensure that the industrial control system is powered off to prevent any electrical accidents. Check the power supply to confirm that it can provide the required voltage range of 35 – 269 V AC at a frequency of 48 – 67 Hz. Use an anti – static wristband and work on an anti – static mat to protect the module from electrostatic discharge, which could damage its sensitive components. Prepare the necessary tools, such as a screwdriver for mounting the module in the control system chassis. Also, ensure that the chassis has an appropriate slot for the Motorola MVME – 605 and that the slot is clean and free from any debris.

Maintenance Suggestions

For regular maintenance of the Motorola MVME – 605, visually inspect the module periodically for any signs of physical damage, such as cracks or loose connections. Check the communication ports for any signs of corrosion or dirt, and clean them if necessary using appropriate cleaning tools. Monitor the module’s power consumption regularly to detect any abnormal increases, which could indicate a malfunction. If the module has a display or status LEDs, use them to diagnose any issues. For example, if an LED indicating communication is not blinking as expected, it could signal a communication problem. In case of a malfunction, first check the connections and power supply. If the problem persists, refer to the module’s documentation to identify possible solutions, such as reconfiguring settings or replacing faulty components. Keep a record of the module’s maintenance history, including any repairs or replacements, to track its performance over time.

Service and Guarantee Commitment

Although the Motorola MVME – 605 is a discontinued product, we are committed to providing support to our customers. We offer a limited 90 – day warranty for refurbished units, covering any defects in materials and workmanship. Our team of experts is available to provide technical support, helping customers with installation, configuration, and troubleshooting. We also maintain a stock of critical spare parts for the Motorola MVME – 605, ensuring that in case of component failures, customers can get their systems back up and running as quickly as possible. We understand the importance of the Motorola MVME – 605 in legacy industrial systems, and we are dedicated to helping customers maintain the reliability and functionality of their existing setups.