Description

Product Overview

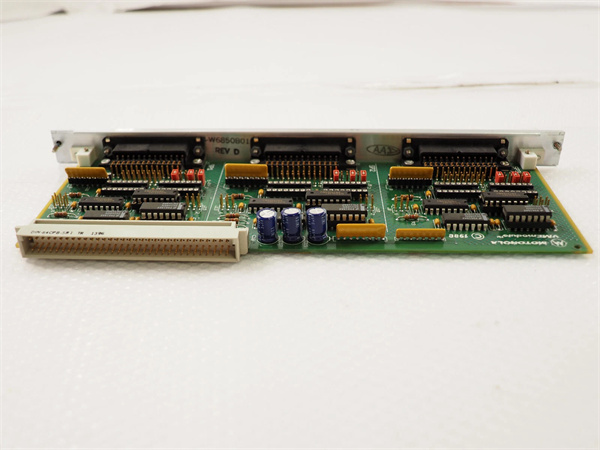

The Motorola MVME – 705 – 1 is a significant component within the Motorola industrial product portfolio. It is a single – slot hot – swappable CompactPCI board equipped with a PowerPC™ series microprocessor, designed to meet the demands of industrial control, data processing, and communication in various industrial applications.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | MVME – 705 – 1 |

| Manufacturer | Motorola |

| Product category | CompactPCI board with PowerPC microprocessor |

| Input power | Operates within a wide voltage range of 89 – 280 VAC, allowing for flexibility in different power supply environments. This is beneficial in industrial settings where power supply conditions may vary. |

| Memory | Features 295 KB of total memory. Specifically, it has 280 KB for application runtime and 630 KB of non – volatile memory for storing application objects, text, and bitmaps. This memory configuration enables efficient operation of applications and storage of important data even during power outages. |

| Shipping weight | Approximately 3.8 lbs per unit, which is relatively lightweight considering its functionality. This makes it easy to handle during installation and transportation within industrial systems. |

| Shipping dimensions | The board has dimensions of 380 x 350 x 20mm, designed to fit standard CompactPCI chassis. Its compact size allows for space – efficient integration into industrial control cabinets. |

| Product life cycle status | Currently in a discontinued/obsolete state. However, it still holds value in existing systems where its functionality meets specific requirements, and spare parts may still be available through certain channels. |

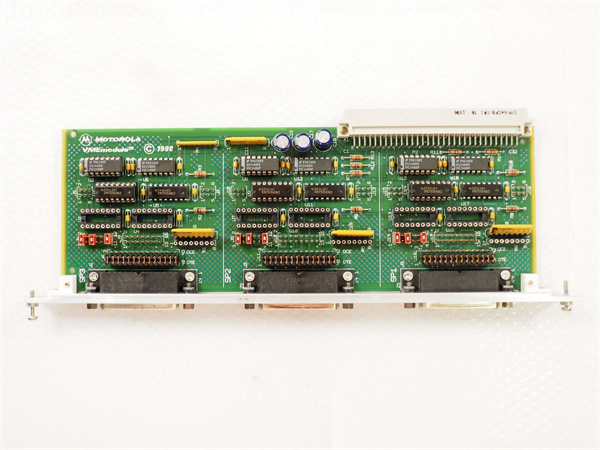

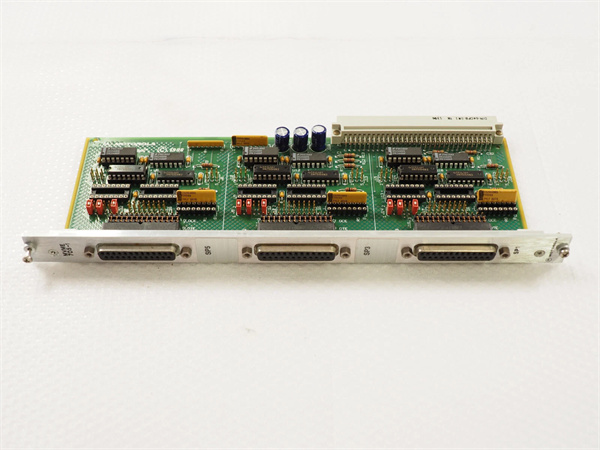

| Communication ports | Equipped with remote I/O (RIO) and an RS – 232 (printer) port. The RIO port enables seamless connection to remote devices for data transfer and control, while the RS – 232 port can be used for interfacing with printers or other serial – based peripherals. |

| Keypad function keys | Comes with 12 function keys (F1…F10), which can be programmed to perform various functions in the context of the industrial application. This provides an easy – to – use interface for operators in industrial settings. |

| Touchscreen | The touchscreen has 180 touch cells with an actuation capacity of 1.5 million presses, ensuring long – term durability. It has a resolution of 120 * 350 and a display area of 125 x 55 mm (4.54 x 3.4 in.), with a green display type. The touchscreen offers an intuitive user interface for interacting with the system. |

| Weight | The actual weight of the unit is 1.8 kg, which is suitable for mounting in various industrial equipment without adding excessive load. |

Motorola MVME-705-1

Product Introduction

The MVME – 705 – 1 serves as a powerful processing and communication hub in industrial systems. Its PowerPC series microprocessor enables efficient data processing, making it suitable for applications that require real – time data analysis and control. For example, in a manufacturing plant, it can be used to process data from multiple sensors located on the production line. The data from temperature sensors, pressure sensors, and position sensors can be fed into the MVME – 705 – 1, which then analyzes this data in real – time to adjust the operation of machinery, ensuring optimal production conditions.

The communication ports play a crucial role in its functionality. The remote I/O (RIO) port allows the MVME – 705 – 1 to communicate with devices located at a distance. In a large – scale industrial complex, it can be used to control and monitor remote equipment, such as motors and valves in a different building or area. The RS – 232 port, on the other hand, is useful for connecting to devices like printers for logging production data or to other legacy serial – based equipment that may still be in use in the industrial environment.

The touchscreen and function keys provide an operator – friendly interface. In a control room, operators can use the touchscreen to access different functions and views of the industrial process. The function keys can be programmed to quickly perform common tasks, such as starting or stopping a production line, or accessing specific diagnostic information.

Core Advantages and Technical Highlights

Powerful Processing Capability: The integration of a PowerPC series microprocessor endows the MVME – 705 – 1 with robust data processing capabilities. It can handle complex algorithms and large amounts of data in real – time. In an industrial automation scenario, it can process data from hundreds of sensors simultaneously, making it possible to make quick decisions and adjustments to the production process.

Flexible Power Input: With an input power range of 89 – 280 VAC, the MVME – 705 – 1 can adapt to different power supply conditions. This is highly advantageous in industrial settings where power quality may vary. For instance, in a factory located in an area with unstable power grids, the MVME – 705 – 1 can continue to operate reliably without the need for additional power conditioning equipment in many cases.

User – Friendly Interface: The combination of a touchscreen and function keys offers a user – friendly interface. The touchscreen’s high – resolution display and durable touch cells make it easy for operators to interact with the system. The programmable function keys enhance the efficiency of operation, allowing operators to perform tasks with a simple press of a button. In a fast – paced industrial environment, this can significantly reduce the time taken to perform operations and minimize errors.

Remote Communication: The presence of the RIO port enables remote communication, which is essential for modern industrial control. It allows for the monitoring and control of equipment from a central location, reducing the need for on – site personnel to constantly check and adjust devices. In a power generation plant, operators can monitor and control the operation of turbines and generators located in different parts of the plant using the MVME – 705 – 1’s remote communication capabilities.

Typical Application Scenarios

Industrial Automation: In a large – scale automotive manufacturing plant, the MVME – 705 – 1 can be used to control and monitor the production line. It can receive data from sensors on the assembly robots, conveyor belts, and quality control stations. Based on this data, it can adjust the speed of the production line, control the movement of robots, and perform quality checks in real – time. For example, if a sensor detects a defective part, the MVME – 705 – 1 can immediately stop the production line and alert the maintenance staff.

Data Logging and Monitoring: In a chemical processing plant, the MVME – 705 – 1 can be used to log data from various sensors, such as temperature, pressure, and chemical composition sensors. The data can be stored in its non – volatile memory and later retrieved for analysis. The RS – 232 port can be used to connect to a printer to generate hard – copy reports. Additionally, the remote I/O port can be used to send summary data to a central control room for continuous monitoring.

Operator Interface in Industrial Systems: In a power distribution substation, the MVME – 705 – 1 can serve as an operator interface. Operators can use the touchscreen and function keys to monitor the status of transformers, circuit breakers, and other electrical equipment. They can also use it to perform operations such as switching on or off equipment, adjusting voltage levels, and accessing diagnostic information.

Motorola MVME-705-1

Related Model Recommendations

Motorola MVME712 – 101: While the MVME – 705 – 1 focuses on processing and local/remote control with its PowerPC microprocessor, the MVME712 – 101 is more centered around communication. In a complex industrial system, the MVME – 705 – 1 can process the data, and the MVME712 – 101 can be used to transmit this data to other parts of the system, such as a central control server or other industrial devices. For example, in a large – scale manufacturing facility, the MVME – 705 – 1 can process production data from the factory floor, and the MVME712 – 101 can send this data to the enterprise – level management system for further analysis.

Motorola MVME162: A high – performance VMEbus single – board computer, the MVME162 can be used in tandem with the MVME – 705 – 1. The MVME – 705 – 1 can handle the user – interface and some basic data processing tasks, while the MVME162 can perform more complex calculations and control functions. In an aerospace component testing facility, the MVME – 705 – 1 can be used as an operator interface to input test parameters, and the MVME162 can process the data from the test sensors and control the testing equipment.

Motorola MVME050: An industrial power supply module, the MVME050 can provide the necessary power for the MVME – 705 – 1 and other components in the industrial system. In a harsh industrial environment, such as a mining site, the MVME050 can ensure a stable power supply to the MVME – 705 – 1, enabling reliable operation. It can also protect the MVME – 705 – 1 from power surges and other electrical issues that may occur in such environments.

Installation, Commissioning and Maintenance Instructions

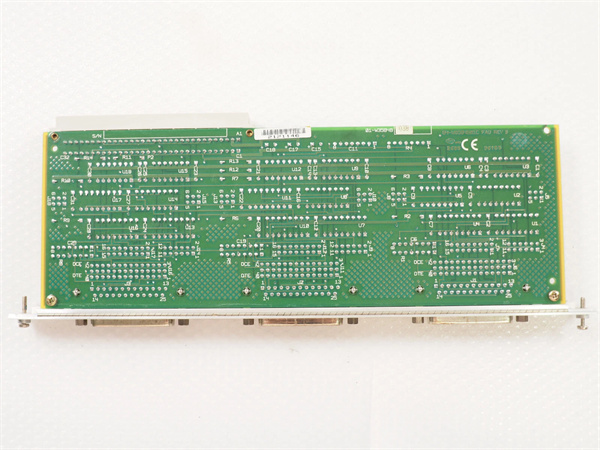

Installation Preparation: Before installing the MVME – 705 – 1, ensure that the CompactPCI chassis is compatible and provides stable power within the specified voltage range. Gather the necessary tools, such as an anti – static wristband to protect the sensitive electronic components, a screwdriver for mounting the board in the chassis, and appropriate cables for connecting to peripheral devices. Check the jumper settings on the board (if any) according to the desired configuration.

Commissioning: After installation, power on the system. Use diagnostic software (compatible with the CompactPCI system) to check the functionality of the MVME – 705 – 1. Verify that the microprocessor is operating correctly, the memory is accessible, and the communication ports are working. Test the touchscreen and function keys to ensure they are responsive. Check the connection to peripheral devices by sending and receiving sample data.

Maintenance Suggestions: Regularly check the status of the MVME – 705 – 1. Inspect the LEDs on the board (if available) to ensure normal operation. Clean the touchscreen periodically to maintain its responsiveness. For the communication ports, check the cables and connections for any signs of wear or damage. If there are any performance issues, first check the power supply and then use diagnostic tools to identify whether it is a hardware – related issue or a problem with the software or connected devices. Store spare MVME – 705 – 1 boards in a static – free environment to maintain their integrity.

Service and Guarantee Commitment

Since the MVME – 705 – 1 is in a discontinued/obsolete state, the standard warranty may no longer be applicable in the same way as for current products. However, some resellers or service providers may offer limited warranties or repair services for a certain period. It is important to check with the specific seller or service provider. For support, although Motorola may not actively develop new software or provide extensive technical support for this model, there are still third – party companies that can offer maintenance, repair, and even some level of software adaptation services. These services can help keep the MVME – 705 – 1 operational in existing industrial systems.