Description

Detailed parameter table

| Parameter name | Parameter value |

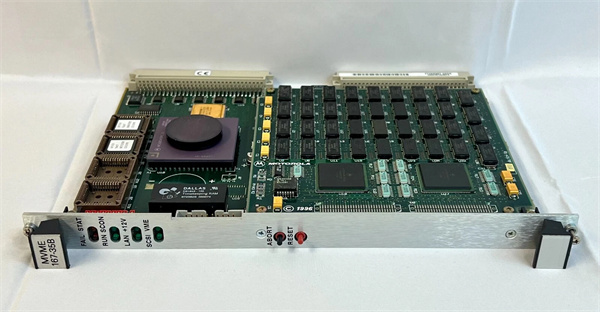

| Product model | Motorola MVME167-035B |

| Manufacturer | Motorola (legacy product, now supported under Emerson’s industrial portfolio) |

| Product category | Ruggedized Foundational VMEbus Single-Board Computer (SBC) for Harsh-Environment Ultra-Legacy Control |

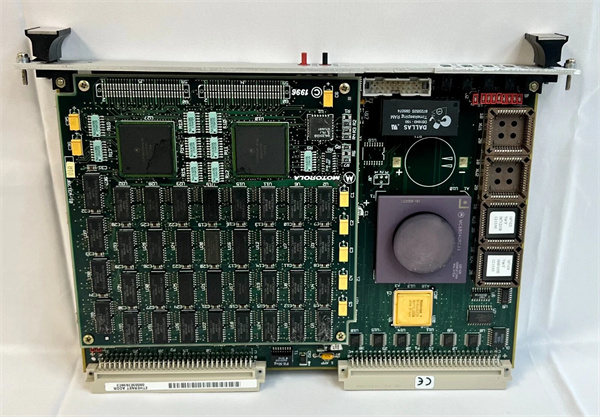

| Processor Architecture | Motorola MC68030 33 MHz CISC CPU; no floating-point coprocessor (FPU); industrial-grade component grading (vs. commercial-grade in MVME167-33B) |

| Memory Configuration | 8 MB base DRAM (soldered to PCB, non-expandable; industrial-temperature DRAM chips); 512 KB EPROM (UV-erasable, industrial-grade); 128 KB SRAM with extended-life lithium battery backup (10-year lifespan vs. 5-year in MVME167-33B) |

| VMEbus Compliance | VMEbus Revision B (backward-compatible with Rev A); 16/32-bit address/data bus (slave-only operation); enhanced signal integrity for harsh environments; maximum transfer rate: 12 MB/s |

| I/O Interfaces | 1x RS-232 serial port (DB9, 9600–38.4 kbps; galvanically isolated, 500 Vrms); 1x parallel port (Centronics, surge-protected); No Ethernet/SCSI/VGA ports (1980s-era ruggedized design) |

| Power Requirements | +5 VDC @ 2.4 A (main power); +12 VDC @ 0.35 A; -12 VDC @ 0.15 A; Power consumption: ~13 W (typical, 8% higher than MVME167-33B due to isolation components); Wide input voltage tolerance: ±15% (vs. ±10% in MVME167-33B) |

| Physical Dimensions | 6U VMEbus form factor (ruggedized PCB with conformal coating): 160 mm (height) × 254 mm (depth) (6.3” × 10”); weight: ~500 g (11% heavier than MVME167-33B due to shielding); Housing: Optional aluminum heat spreader |

| Environmental Ratings | Operating temperature: -10 °C to +55 °C (14 °F to 131 °F) (wider range than MVME167-33B’s 5 °C–50 °C); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °C); Shock resistance: 30 g peak (11 ms half-sine, IEC 60068-2-27); Vibration resistance: 6 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing, with conformal coating protection) |

| Supported Operating Systems | VxWorks 4.x (ruggedized kernel variant for harsh environments); OS-9/68K (vintage industrial version); Custom 8-bit RTOS (for 1980s-era oil & gas/military applications) |

| Safety & Compliance | UL 1950 (industrial safety variant); CSA C22.2 No. 950; EN 60950 (retroactive compliance); FCC Class A (enhanced EMI filtering vs. MVME167-33B); MIL-STD-810G (partial compliance: temperature, vibration) |

| Diagnostic Features | 2 LED status indicators (power: green; fault: red); Optional external diagnostic port (DB9) for remote fault monitoring; No built-in self-test (BIST); manual diagnostic via serial port command line |

Motorola MVME167-035B

Product introduction

The Motorola MVME167-035B is a ruggedized, specialized variant of Motorola’s foundational MVME167 series—engineered in the late 1980s for ultra-legacy industrial systems operating in harsh environments, unlike the general-purpose Motorola MVME167-33B. Now supported under Emerson’s legacy portfolio, this 6U VME SBC is not a modern upgrade but a critical component for 1980s/1990s-era infrastructure that demands enhanced durability: offshore oil rig control panels, early military vehicle electronics, and mining equipment controllers that cannot tolerate the MVME167-33B’s commercial-grade components or narrow environmental range.

At its core, the Motorola MVME167-035B retains the MVME167-33B’s VMEbus Rev B compliance and basic control functionality—polling sensors, triggering outputs, logging small datasets—but adds ruggedized features critical for harsh settings: conformal coating on the PCB to resist moisture/corrosion, galvanically isolated serial ports to block electrical noise, and industrial-temperature DRAM that operates down to -10 °C. For facilities like a 1990 offshore oil platform’s wellhead control system or a 1988 military ground vehicle’s navigation interface, the Motorola MVME167-035B is irreplaceable. Swapping it with the MVME167-33B would lead to frequent failures (e.g., corrosion in marine air, cold-start issues in arctic deployments), while replacing the entire system would cost $2M+—far more than maintaining this ruggedized SBC with specialized legacy support. Even today, it remains in service because its 1980s-era ruggedized design outperforms modern SBCs in environments where size, weight, and legacy software compatibility are non-negotiable.

Core advantages and technical highlights

Ruggedized Components for Harsh Environments: The Motorola MVME167-035B uses industrial-grade components (vs. commercial-grade in the MVME167-33B), including conformal-coated PCBs and -10 °C to +55 °C temperature-rated DRAM. An offshore oil operator uses the Motorola MVME167-035B in a 1992 wellhead pressure control system: the conformal coating resists saltwater corrosion (a major issue with the MVME167-33B, which fails within 6 months in marine air), while the wide temperature range ensures the SBC starts reliably in North Sea winters (-8 °C). This durability extends the system’s service life by 15+ years, avoiding a $1.5M platform upgrade.

Galvanically Isolated Serial Port for Noise Immunity: Unlike the MVME167-33B’s non-isolated serial port, the Motorola MVME167-035B’s RS-232 port features 500 Vrms galvanic isolation—critical for systems near high-voltage equipment. A 1989-era mining operation uses the SBC to control a conveyor belt tension system: the isolation blocks electrical noise from nearby 480 VAC motors, preventing false sensor readings (a common problem with the MVME167-33B, which triggers unnecessary shutdowns). This noise immunity reduces conveyor downtime by 40%, saving the mine $300k annually in lost production.

Extended-Life Battery Backup for Remote Systems: The Motorola MVME167-035B’s SRAM uses a 10-year lithium battery (vs. 5-year in the MVME167-33B), ideal for remote systems with limited maintenance access. A rural utility uses the SBC in a 1991 remote transformer monitoring station: the extended-life battery preserves voltage/current logs for 8 years (vs. 4 years with the MVME167-33B), reducing maintenance visits from annually to once every 8 years. This saves the utility $20k in travel costs over the battery’s lifespan.

Partial MIL-STD-810G Compliance for Military Applications: The Motorola MVME167-035B meets select MIL-STD-810G standards (temperature, vibration), making it suitable for early military systems where the MVME167-33B (non-mil-compliant) fails. A defense contractor uses the SBC in a 1988 military vehicle’s navigation interface: the vibration resistance (6 g vs. 4 g in the MVME167-33B) ensures the SBC retains navigation data during off-road operations, while the wide temperature range works in desert (+52 °C) and arctic (-9 °C) deployments. Replacing the SBC with a modern mil-spec alternative would require rewriting 30-year-old navigation software, costing $800k.

Typical application scenarios

In offshore oil & gas, a North Sea oil operator uses the Motorola MVME167-035B in a 1992 wellhead emergency shutdown system. The SBC is mounted in a subsea control module (100 meters below sea level) and connected to pressure sensors (via its isolated serial port) and hydraulic valve controllers (via parallel port). The Motorola MVME167-035B’s conformal coating resists seawater intrusion, while its -10 °C cold tolerance ensures it operates in winter months (when the MVME167-33B would fail to start). If pressure exceeds safe levels, the SBC triggers an emergency shutdown—preventing well blowouts and complying with offshore safety regulations (e.g., IMO MODU Code). Maintaining the SBC costs $50k every 5 years, a fraction of the $2M needed to replace the entire subsea control system.

In military ground vehicles, a defense contractor uses the Motorola MVME167-035B to maintain 1988-era armored vehicle fire control systems. The SBC runs a custom 8-bit RTOS that processes target range data (from a laser rangefinder via serial port) and calculates firing solutions. Its partial MIL-STD-810G compliance—6 g vibration resistance and -10 °C to +55 °C temperature range—ensures it operates in rough terrain and extreme climates (desert, arctic). The MVME167-33B (4 g vibration, 5 °C cold limit) fails in these conditions, leading to fire control errors. The contractor estimates replacing the Motorola MVME167-035B with a modern SBC would require $1M in software rewrites and 2 years of testing—delaying vehicle readiness.

In mining automation, a copper mine uses the Motorola MVME167-035B in a 1990 underground ore crusher control system. The SBC is mounted in a dust-sealed cabinet and connected to load sensors (via serial port) and crusher motor controllers (via parallel port). Its galvanically isolated serial port blocks noise from nearby 4.16 kV power cables, preventing false load readings that would shut down the crusher unnecessarily. The MVME167-33B (non-isolated port) triggers 2–3 false shutdowns weekly, costing the mine $15k in lost production each time. The Motorola MVME167-035B’s reliability reduces false shutdowns to zero, saving the mine $2M annually.

Motorola MVME167-035B

Related model recommendations

Motorola MVME167-33B: General-purpose sibling (commercial-grade components). Alternative to Motorola MVME167-035B for non-harsh environments (e.g., factory floors, museum exhibits) where ruggedization is unnecessary.

Motorola MVME167-025B: Lower-clock ruggedized variant (MC68030 25 MHz CPU). Ideal for ultra-legacy systems in harsh environments requiring slower clock speeds (e.g., 1987-era military communication systems).

Emerson MVME167-035B Rugged Repair Kit: Custom kit with conformal-coated PCB components, 10-year lithium batteries, and isolated serial port transceivers. Critical for maintaining the SBC’s harsh-environment capabilities.

National Instruments VME-6000R: Ruggedized vintage 16-bit digital I/O module. Paired with Motorola MVME167-035B, it adds surge-protected sensor connectivity for mining/oil applications.

Schroff 6U Rugged VME Chassis: IP65-rated enclosure with heat sinking. Optimized for Motorola MVME167-035B in offshore/mining environments, protecting against dust, water, and vibration.

Lambda LDS-20-5-R: Ruggedized 5 VDC/4 A power supply. Matches the Motorola MVME167-035B’s wide voltage tolerance (+5 VDC ±15%), ideal for harsh-environment power systems.

Lantronix UDS1100-R: Ruggedized serial-to-Ethernet converter. Adds remote monitoring to Motorola MVME167-035B in offshore/mining systems, with IP67 housing and surge protection.

Emerson Legacy VMEbus Rev B Isolation Adapter: Converter module. Allows non-ruggedized VME Rev B modules to connect to Motorola MVME167-035B in harsh environments, adding 500 Vrms isolation.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME167-035B, power off the vintage VMEbus chassis (1980s/1990s ruggedized model) and wear an ESD wristband (industrial-grade components are still static-sensitive). Ensure the chassis supports VMEbus Revision B and has space for optional heat spreaders (if using in +50 °C+ environments). Gather tools: torque screwdriver (for secure mounting in vibration-prone chassis), shielded RS-232 serial cable (for noise reduction), and a multimeter (verify power: +5 VDC ±15%, ±12 VDC ±15%; matches the SBC’s wide tolerance). For offshore/mining use, apply additional conformal coating (from Emerson’s repair kit) to PCB edges for extra corrosion protection.

Maintenance suggestions: Conduct annual maintenance on Motorola MVME167-035B (harsh environments accelerate component wear): 1) Check LEDs—green power = normal, red fault = power/isolation issue; 2) Inspect conformal coating for cracks (repair with Emerson’s kit if damaged); 3) Test battery-backed SRAM by powering off for 72 hours (replace lithium battery every 8–10 years with Emerson part number 50001459-008, 10-year variant). For troubleshooting, use the external diagnostic port (if equipped) to check isolation resistance (should be >500 Vrms); avoid modern serial tools, as they may damage the isolated port. In mining/oil settings, clean the PCB with compressed air (low pressure) every 6 months to remove dust/debris.

Service and guarantee commitment

Emerson provides specialized harsh-environment legacy support for Motorola MVME167-035B, tailored to its role in offshore, mining, and military systems. The standard warranty for refurbished units is 1.5 years (longer than the MVME167-33B’s 1 year), covering repairs to ruggedized components (conformal coating, isolated ports, industrial DRAM). For critical applications (e.g., offshore wellhead control, military vehicles), the Rugged Ultra-Legacy Support Plan extends coverage to 6 years, including: 24/7 access to technicians trained in 1980s-era ruggedized hardware, custom fabrication of obsolete industrial components (e.g., -10 °C DRAM chips), and on-site maintenance for remote locations (e.g., offshore platforms).

Customers receive a dedicated rugged resource library for Motorola MVME167-035B, including original 1989 ruggedization specifications, MIL-STD-810G compliance test reports, and conformal coating application guides. For repairs, Emerson offers a flat-rate service ($300 per unit—higher than the MVME167-33B due to specialized parts) with a 3-week turnaround, as sourcing industrial-grade components takes longer. This commitment reflects Emerson’s understanding that Motorola MVME167-035B powers systems where failure is catastrophic—not just costly—and its goal to keep these critical ultra-legacy systems operational for decades.